Description

|

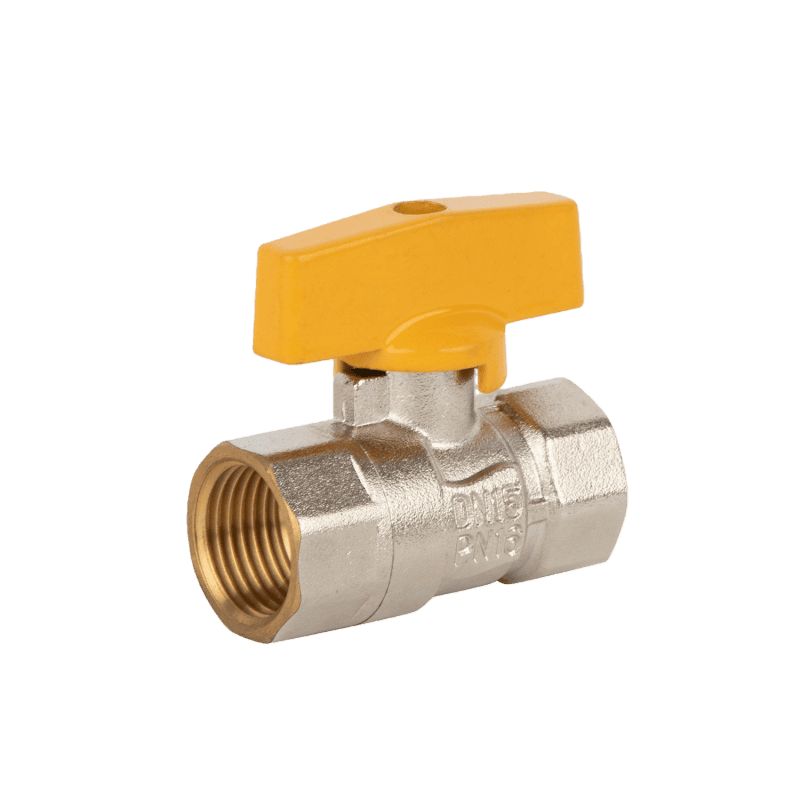

1/2″ Straight Through Type Brass Ball Gas Valve

Brass Ball Gas Valve is a straight-through brass gas ball valve, which is the core control accessory in the gas transmission system. It is widely used in residential gas pipelines, commercial kitchen gas equipment, industrial gas transmission pipelines, and other settings. It is suitable for natural gas, liquefied gas, and other gas types. The straight-through structure design ensures smooth gas circulation without obvious resistance. The rapid opening and closing of the valve is realized through the rotation of the ball. The control is accurate, and the operation is convenient. At the same time, the sealing performance is excellent, which can effectively prevent gas leakage. It is a key component to ensure the safe operation of the gas system and prevent gas leakage risk. It is also often used for maintenance and daily switch control of gas equipment.

|

|

|

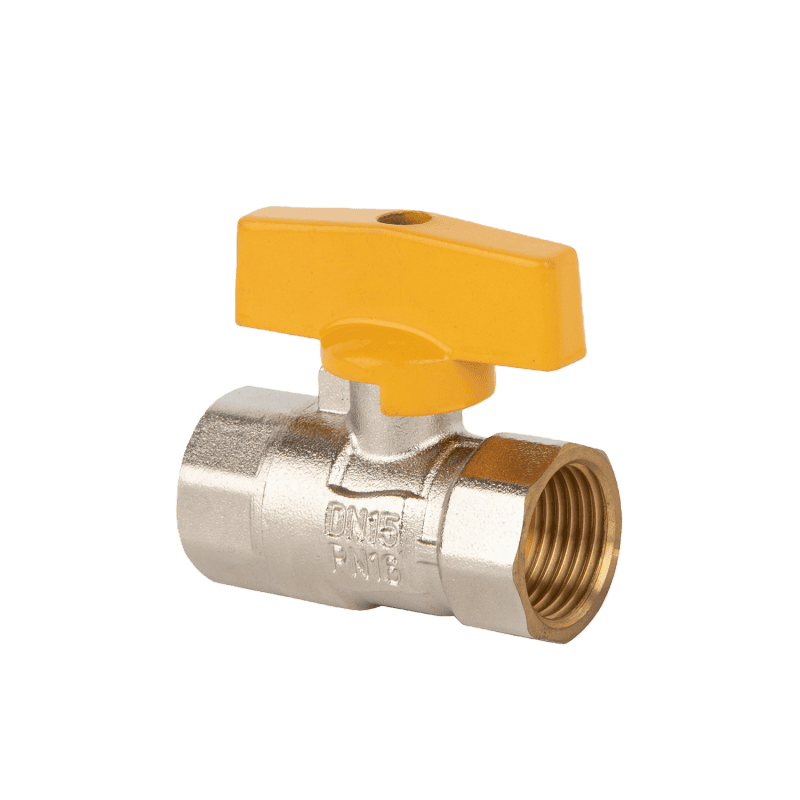

M1/2″X F1/2″ Gas Ball Valve with Butterfly Handle Gas ball valve with butterfly handle, made of brass material, is the core control accessory in the gas transmission system, widely used in residential gas pipeline, commercial kitchen gas equipment, industrial gas pipeline, and gas water heater, gas stove, and other terminal equipment connection control scenes. The double interface design of external thread and internal thread can flexibly adapt to the gas pipeline or equipment interface of the same specification, which is convenient to install and firmly connected; the butterfly handle design is labor-saving and easy to operate, and the gas supply can be quickly opened or cut off by rotating the handle. The control is accurate and efficient, and the sealing performance is excellent. It can reliably block the gas circulation, which is not only convenient for the gas switch control in daily use, but also convenient for the maintenance of gas equipment. It is a key component to ensure the safe and stable operation of the gas system.

|

|

|

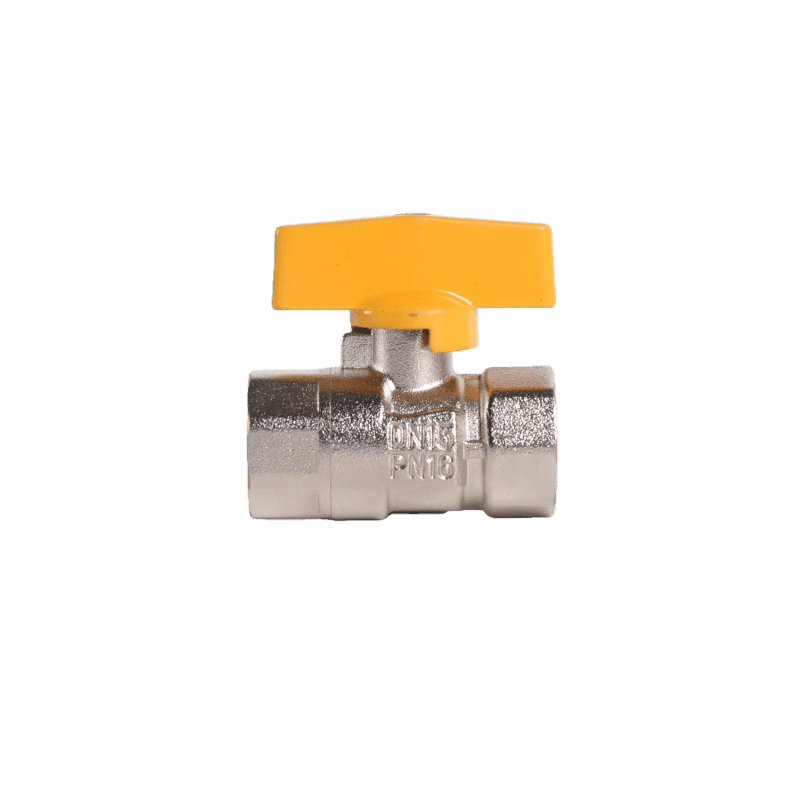

PTFE Seal Brass Gas Cock Valves

The brass gas angle ball valve is the core accessory of the gas transmission system with control and steering functions. It is suitable for a small installation space where the gas flow direction needs to be changed. Angular structure design can realize 90-degree turning of the gas pipeline, adapt to complex pipeline layout, and integrate the precise control function of the gas cock. Gas supply can be quickly opened or cut off by rotating the valve handle. Easy operation and reliable sealing performance

|

|

Pressure Relief Boiler Gas Brass Safety Valve

The special pressure relief valve for boiler gas is a core protective component in the boiler gas system to ensure operational safety. It is widely used in the pipeline system of gas heating equipment, such as industrial boilers, commercial gas boilers, and heating boilers. Built-in accurate pressure sensing mechanism, when the gas or steam pressure in the boiler exceeds the preset safety value, it will automatically open the pressure relief channel to release excess pressure, and automatically close it when the pressure drops to a safe range. The core purpose is to prevent the boiler from causing explosions, leaks, and other safety accidents due to excessive pressure. It is an indispensable safety protection accessory for boiler equipment in industrial production and civil heating.

|

|

|

Lead-free Brass Ball Valve FXM Lead-free brass ball valve accurately controls the opening, closing, and on-off of fluid in the pipeline to ensure safe use. Widely used in drinking water pipelines, food processing equipment, medical water systems, household bathroom pipelines, and industrial clean fluid transmission scenarios, suitable for water, gas, neutral liquid, and other media. Ball valve structure design makes it easy to switch operation (90-degree rotation can be completed on and off), excellent sealing performance, can effectively prevent fluid leakage, while adapting to different specifications of the pipeline system

|

|

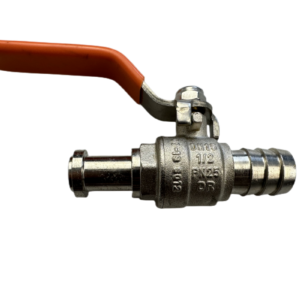

1/4 turn Lead-free press ball valves PEX Lead-free press ball valves 1/4 rotary crimp gas ball valves made of lead-free brass are the core accessories for fluid control in PEX piping systems, widely used in residential and commercial drinking water delivery systems, hot water circulation systems, and HVAC scenarios. 1/4 rotation operation mode with handle, can quickly open or cut off the fluid, labor-saving operation and accurate control, crimping interface can be quickly connected with PEX pipeline through copper snap ring and other accessories, installation without welding or gluing, adapt to narrow installation space, while the full diameter design can reduce fluid pressure loss, excellent sealing performance can prevent leakage, not only to ensure efficient circulation of the pipeline system, but also to facilitate the later maintenance of pipelines and related equipment.

|