Description

|

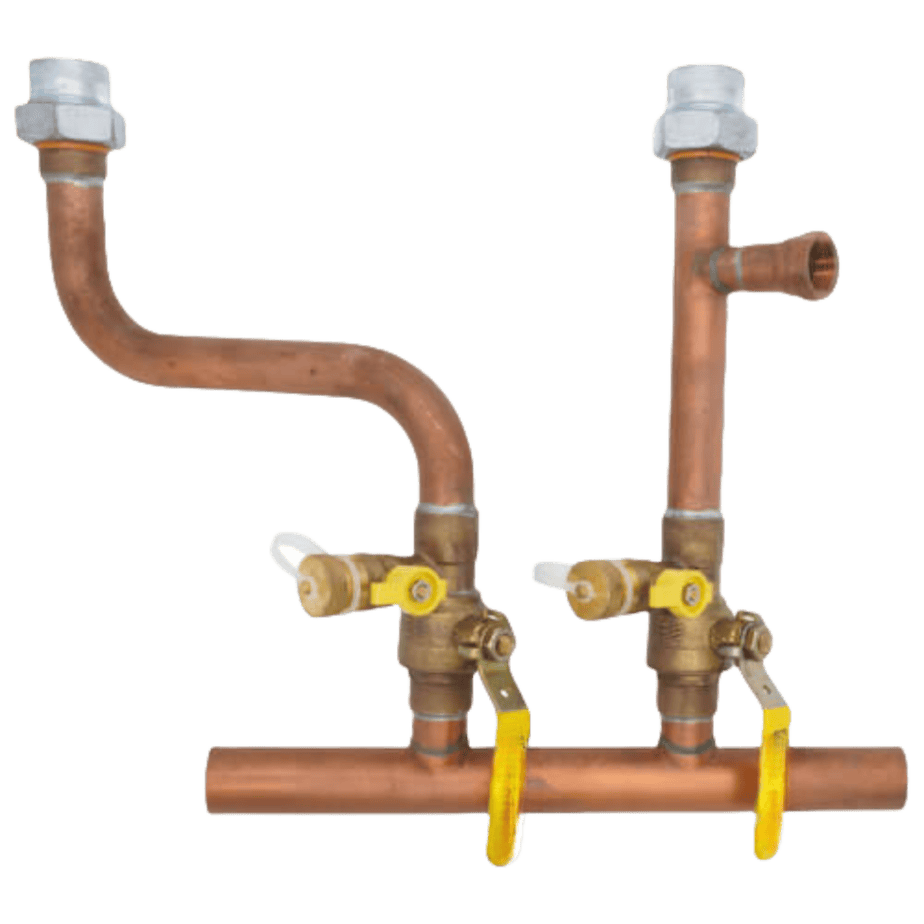

Flow Heating and Water Supply Manifolds

Flow Heating and Water Supply Manifolds are designed for use in underfloor heating systems to control the flow rate and distribution of water through the entire heating system. This manifold is installed in the center of the system. One end is connected to the supply line responsible for hot water transmission. The other end is connected to the return line that carries heat and returns it.

|

|

|

Refrigerant Manifold Pressure Gauge

A refrigerant manifold pressure gauge is a common tool used when fixing or checking air conditioners and cooling systems. It is used to see the pressure on the high side and the low side of the system at the same time. The function is to feed back the pressure state of refrigerant in the system in real time, and assist in vacuum pumping, refrigerant filling, troubleshooting, and other operations.

|

|

|

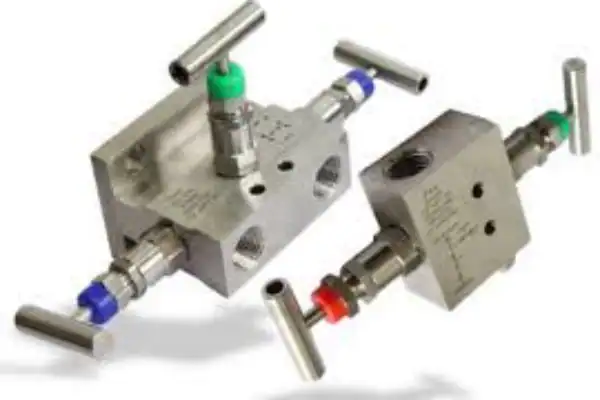

Thermostatic valve for distributors

Thermostatic valves for distributors are small temperature control parts used in heating and water supply systems. They are installed on the distributor and can sense the temperature of the water inside. This helps keep the temperature at a suitable level and makes the system run more smoothly and safely. The function is to maintain the set temperature of each branch of the distributor.

|

|

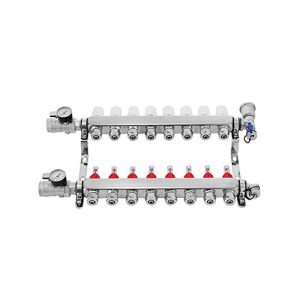

Stainless Steel Manifold A stainless steel manifold is a part used to share and control water or gas. It is made of stainless steel and has many ports on one body. These ports can connect to different pipes and devices. It is often used in factories, heating and water systems, labs, and energy equipment. The manifold helps send water or gas to many places at the same time, or control each line separately. It also makes it easier to adjust the flow and check the pressure. Using a manifold keeps the pipes neat and reduces messy piping.

|

|

|

Nickel Plating On Radiator Manifold

Nickel Plating on Radiator Manifold is a nickel plating process on the surface of the radiator manifold. It effectively resists oxidation and corrosion of the water quality. Moisture in the heating system prolongs service life. It can also enhance surface hardness and wear resistance. Reduces scratch damage and ensures radiator manifold operation in long-term medium transmission and environmental contact.

|

|

Manifold Drain Valve

Manifold drain valves are special valves installed on water or gas manifolds. They usually have a sealed connection and a simple handle to operate. The function is to quickly discharge the residual medium in the manifold and downstream pipeline. It not only avoids freezing and cracking of the pipeline caused by accumulated water in a low-temperature environment, but also removes dirt deposited in the system to ensure smooth circulation of the medium.

|