FAQs of Automatic Air Vent

1. Does the choice of float material affect the performance of the Automatic Air Vent?

In automatic air release valves, the material used for the float is very important, as it directly affects the performance and service life.

First is sensitivity. The material properties of the float need to be light and hard. The float needs to be light to be sufficiently sensitive to the opening and closing of the valve. However, overly soft materials can cause the float to deform easily, resulting in uneven air release.

Second is durability. Air release valves are often used in hot water pipes, where the temperature is high, and they are used for a long time. Materials such as stainless steel, PP plastic, or those with anti-corrosion treatment are not prone to rusting or deformation and will not get stuck even after long-term use. Ordinary plastics or iron parts may age and crack after a period of use, affecting the sealing.

Finally, there is the service life. Good materials can generally last five to ten years, being stable and reliable; poorer materials may have problems in one or two years and need to be replaced frequently.

Plumberstar commonly uses PP floats, which are lightweight, heat-resistant, and durable, and remain relatively stable when used in hot water and humid environments for a long time.

2. Do you perform 100% pressure testing on automatic air vents?

Yes, we conduct 100% pressure testing on all automatic exhaust valves before they leave the factory.

1. Testing standards and parameters: The inlet pressure of the automatic exhaust valve will be set to 1.5 times the maximum working pressure. The testing time for the automatic exhaust valve is 3–5 minutes. The purpose of testing under continuous duration and overpressure environment is to check whether the product can withstand high pressure without deformation or leakage.

2. Testing methods: The factory uses automated pressure testing equipment. Water is injected into the valve cavity to build up pressure, and high-precision pressure gauges and leak detectors are used to monitor pressure changes in real time. Any product with a pressure drop exceeding 5% or visible leakage will be marked as unqualified. It needs to be registered and then reworked or scrapped.

3. Traceability: Each tested product will have its own batch number. The pressure test data will be recorded in the quality management system to achieve full traceability.

3. Can your air vents be used in government projects?

Yes, Plumberstar’s air release valves are fully suitable for government projects! Our automatic air release valves are highly compatible with the strict requirements of government-led infrastructure, public buildings, and public facility projects.

First, the core requirement of government projects is compliance with product standards. Our air release valves meet multiple international and regional technical specifications. They have obtained CE certification, GS certification, RoHS certification, and UL certification. It enables them to be used in regions such as Europe and the United States.

Secondly, the diversification of government projects requires our automatic exhaust valves to be adaptable to multi-scenario applications. Our exhaust valves are compact in design and can be installed flexibly. They can be used both indoors and outdoors. It is more suitable for use in large-scale projects. It also supports low-carbon operation, which is in line with the energy conservation and emission reduction goals of government projects.

Finally, whether it is for government-managed public buildings, infrastructure, or historical building renovation projects, our automatic air release valves can provide compliant and reliable solutions. We can also support the customization of product parameters, according to the specific standards and technical specifications of government projects. To ensure full compliance with project requirements.

4. Can you assist with processing the export documents for the Automatic Air Vent?

Yes, Plumberstar’s air release valves are fully suitable for government projects! Our automatic air release valves are highly compatible with the strict requirements of government-led infrastructure, public buildings, and public facility projects.

First, the core requirement of government projects is compliance with product standards. Our air release valves meet multiple international and regional technical specifications. They have obtained CE certification, GS certification, RoHS certification, and UL certification. It enables them to be used in regions such as Europe and the United States.

Secondly, the diversification of government projects requires our automatic exhaust valves to be adaptable to multi-scenario applications. Our exhaust valves are compact in design and can be installed flexibly. They can be used both indoors and outdoors. The material of the exhaust valve is lightweight and corrosion-resistant, with a long service life. It is more suitable for use in large-scale projects. It also supports low-carbon operation, which is in line with the energy conservation and emission reduction goals of government projects.

Finally, whether it is for government-managed public buildings, infrastructure, or historical building renovation projects, our automatic air release valves can provide compliant and reliable solutions. We can also support the customization of product parameters. It adheres to the specific standards and technical specifications of government projects. To ensure full compliance with project requirements.

5. Can you ship to multiple destinations in one Automatic Air Vent order?

Yes, we fully support the delivery of a single automatic exhaust valve order to multiple destinations. Ideal for customers who have warehouses in multiple locations.

Order Delivery: Customers only need to place a large total order after providing a detailed multi-address. We can handle the rest. We will complete the packaging in our own factory. Once completed, the goods are split into separate shipments for distribution. Order management is simplified by not placing multiple orders.

Destination flexibility: We collaborate with professional ocean freight forwarders. We have rich experience in transporting goods. Our aim is to achieve door-to-door delivery. Give customers the best service experience. We can deliver goods anywhere in the world, including overseas countries/regions, project construction sites, and warehouses.

Tracking and after-sales coordination: each package will be assigned a separate logistics number. It enables the consignee to monitor the delivery status in real time. Suppose there is a problem with a destination. Our logistics team will coordinate with the carrier to ensure that all parties can receive goods smoothly.

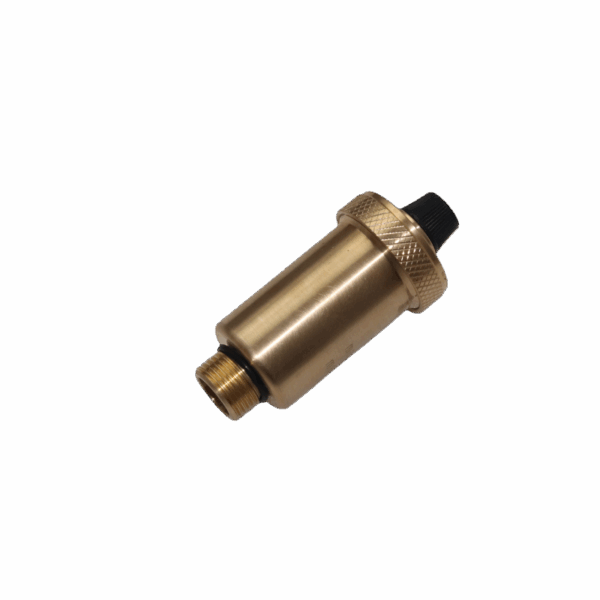

6. Are brass automatic air vents better than plastic ones?

The main difference between brass automatic air vent valves and plastic automatic air vent valves lies in their usage environments and requirements.

Brass automatic air release valves are suitable for scenarios with high reliability requirements. In high-temperature and high-pressure systems, industrial complex water quality, and public infrastructure are considered. They are heavier and more costly. However, our brass automatic air release valves have a longer service life than engineering plastic automatic air release valves. For some long-term use scenarios, brass air release valves offer higher cost performance. Of course, if they are only used in daily working conditions of 0-80°C, engineering plastic air release valves can already meet the needs of small commercial systems. It is still necessary to make a comprehensive judgment based on your usage scenarios, budget, and other aspects.

7. How fast do you respond to technical inquiries for the Automatic Air Vent?

The working hours of our technical team are 9:00-18:00 GMT+8. If you send a message within this time, you will receive an immediate reply.

For general technical issues that can be resolved online, we guarantee that they will be handled within one working day. For some complex technical issues, we will hold a meeting within four hours to propose a solution, and provide a complete solution and operation suggestions within 1-2 working days. For urgent consultations related to project progress or emergency failures, we provide a 24-hour emergency contact channel. Technical experts will respond within 1 hour, provide immediate guidance, and continue to follow up and support until the problem is resolved.