Description

|

|

Pressure Reducing Valve

This pressure-reducing valve has an internal pressure-sensing spool. It reacts to outlet pressure and adjusts the valve opening automatically. There’s an adjustment knob on top. Users can set the outlet pressure easily with it. This makes the valve fit different system requirements. It’s commonly used in water supply lines, boiler branch systems, and industrial pipelines.

|

|

|

Brass Automatic Boiler Fill Valve This brass automatic boiler fill valve is a pressure-activated water refill device. It’s made for hot water and hydronic heating boiler systems. When the system pressure drops below the set level, the valve opens on its own. It refills water into the boiler automatically. When pressure goes back to normal, the valve shuts off right away. No manual operation is needed at all. There’s an adjustment knob on it. You can set the refill pressure easily with it. It fits different boiler types and system setups perfectly.

|

|

|

Nickel-Plated Radiator Valve

This nickel-plated radiator valve is a three-way flow control fitting used in heating systems. It has three ports and is designed for water distribution and collection in radiator branch circuits. The three-port layout lets it connect the main heating pipe and individual radiators at the same time. This simplifies the pipe setup and avoids the need for extra adapters. The valve allows manual flow adjustment to control how much heat each radiator gives off. It also helps balance the system, reducing uneven heating and keeping room temperatures more stable across the whole system.

|

|

|

4-Way Fan COil Valve

This 4-way fan coil valve is used for water flow control in fan coil unit (FCU) systems. It has four ports that match the water connections between the fan coil and the main pipeline. The four-port design allows it to connect the fan coil inlet, outlet, and the system pipes at the same time. It can open or shut off the water flow, and it also supports flow direction change when needed. A white knob on the top is used for manual control. By turning the knob, the valve opening can be adjusted to control the flow rate and meet the cooling or heating needs of the fan coil. It is a key control component for water circuits in central air conditioning fan coil systems.

|

|

|

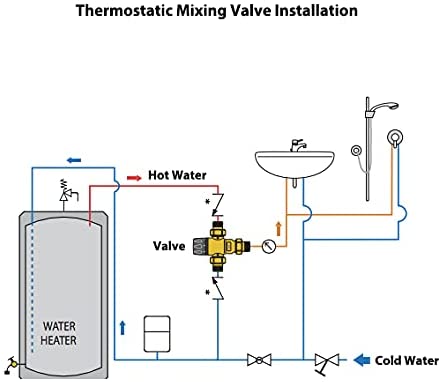

Thermostatic Mixing Valve

This thermostatic mixing valve controls and stabilizes water temperature. It adjusts the mixing ratio automatically. This keeps the outlet water temperature steady. It also prevents sudden hot or cold water shocks. There’s a control knob on top. Users can easily set the desired temperature with it. It’s usually used in shower systems, underfloor heating manifolds, and similar setups. Stable water temperature makes the use more comfortable. It also reduces the risk of scalding.

|

|

3 Way Thermostatic Mixing Valve

This 3-way thermostatic mixing valve is used to control water temperature in multi-branch plumbing and underfloor heating systems. It outputs mixed water with a stable temperature. Perfect for underfloor heating zones and bathroom systems with multiple water outlets. There’s an orange knob on top. You can turn it by hand to set the needed temperature. It’s a key temperature control part. Great for systems that need a stable and reliable mixed water supply.

|