FAQs of Stainless steel 2piece ball valve

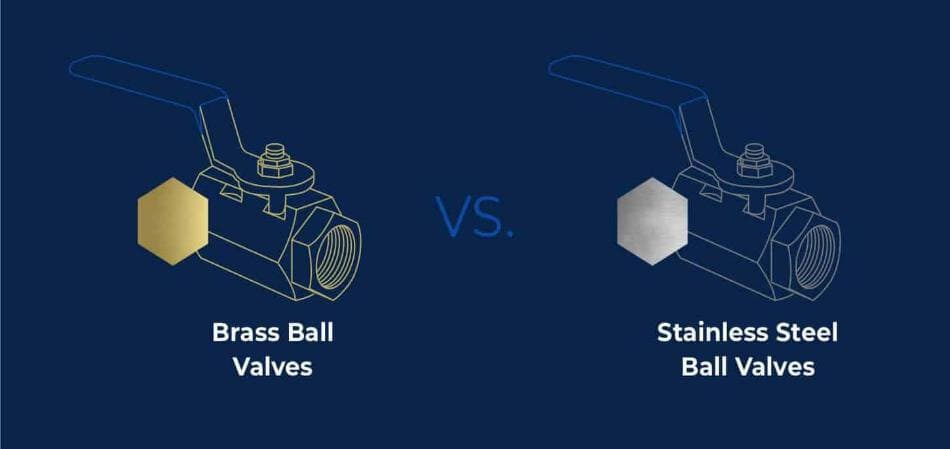

1. What material is the valve seat of a stainless steel 2-piece ball valve?

Plumberstar stainless steel 2-piece ball valves use PTFE valve seats.

PTFE seats work well in high and low temperatures. They resist acids, alkalis, oil, and many other chemicals. They have low friction, open and close smoothly, seal tightly, and last long.

They fit most media, such as water, gas, oil, steam, weak acids, and weak alkalis. They work for daily pipelines, heating, the chemical industry, and water treatment.

If you have special working conditions, we can offer other custom seats: reinforced PTFE, RPTFE, Viton, NBR, and more. They suit higher temperatures, stronger corrosion, or special media.

All valve seats pass strict seal and wear tests. They still seal well after thousands of openings and closings, no leaks or failures. They match the stainless steel valve body perfectly. This makes the whole valve more stable and durable.

2. Can the stainless steel 2-piece ball valve provide drawings customization?

Yes, Plumberstar provides drawing customization services. Our engineers can make professional drawings and produce products based on your actual working conditions, installation space, connection needs, and project standards.

We can adjust and optimize many parts of the ball valve: overall structure, connection type, port size, flange, thread standard, valve length, mounting holes, handle style, and more. We can use your original drawings, design plans, or parameters. We can also redraw 2D or 3D drawings to meet your standards, including ASME, DIN, GB, JIS, and others. We make sure the product fits your size, structure, seal, and installation needs.

Once you confirm the drawings, we make samples and mass-produce according to the final version. Bulk products will be exactly the same as the customized drawings.

If you have functional or usage requirements,our technical team can design the drawings first. We check details with you: structure, size tolerance, seal type, and pressure level. We communicate efficiently until you are satisfied.

All customized drawings are properly saved. It’s easy for reorders, changes, or technical tracing. We make sure every batch of products is stable and consistent.

3. Does the stainless steel 2-piece ball valve support third-party inspection?

Plumberstar stainless steel two-piece ball valves fully support third-party testing. We can meet all your requirements for process, material, and product quality.

We can cooperate with any third-party testing company you choose,including big international names like SGS, BV, ITS, TÜV, and also professional domestic labs.

We can conduct tests on material composition, size tolerance, pressure testing, sealing performance, appearance checks, packaging, and standard compliance. We fully follow your or the project’s standards.

What’s more, we also have our own laboratory. Before production and delivery, we conduct internal inspections. We make sure all indexes are qualified, so third-party testing can pass easily.

We provide complete documents on time as required: raw material reports, production records, drawings, parameter sheets, and factory inspection reports. This makes testing smooth and efficient.

For foreign trade, engineering projects, and bidding that require official test reports, we work closely, communicate in advance, and follow up throughout the process. We help you pass inspection, customs clearance, and acceptance without worries.

4. Can you customize the manual for stainless steel 2-piece ball valves?

Of course, Plumberstar can make professional, standard product manuals for you. They fit export and engineering projects and match your brand, market, and product needs.

- We can do professional layout and design using your information: logo, company details, contact info, product parameters, technical standards, installation steps, maintenance, and safety notes.

- We also support Chinese, English, and other languages. This works for users, customs, and acceptance in different countries.

- We can make manuals in your required format, size, paper, and printing style. They will match your packaging and brand image, making your products look more professional.

For long-term customers, we save all customized manuals. You can use them directly for later orders. This keeps your product materials stable and consistent.

5. What is the MOQ of the OEM stainless steel 2-piece ball valve order?

Plumberstar stainless steel 2-piece ball valve OEM has a flexible MOQ. It fits you whether you’re doing market trials or long-term bulk cooperation.

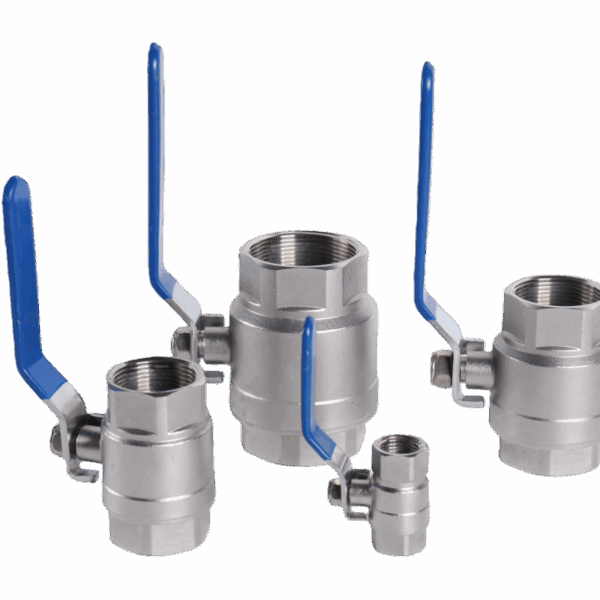

Basic OEM (logo / simple customization)MOQ: 100 pcs per sizeFor regular sizes like DN15–DN50, 1/4″–2″.Only needs small trial orders or restocks with logo engraving/labeling and package marking. Low risk for you to enter the market.

Standard bulk OEMMOQ: 500–1000 pcs per sizeFor bulk orders of regular models.Includes full OEM: logo, color box, manual customization, etc.Better overall cost, good for foreign trade wholesalers and engineering customers.

In-depth customized OEM (structure/size/material)MOQ: 1000 pcs per sizeFor non-standard sizes, special connections (flange, special thread), custom material (316L), special seal or handle. These need mold or process changes, so a higher MOQ keeps production and cost stable.

For new customers’ first order, we support small trial orders of 50–100 pcs for testing and market check. If you order multiple sizes together, we can lower the single-size MOQ when the total quantity meets the standard. This makes mixed orders more flexible.

6. Can the packaging of the 2-piece ball valve be customized?

Plumberstar stainless steel 2-piece ball valves support custom packaging. We can make professional, safe, export-standard packaging that fits your brand and market needs.

We can adjust both inner and outer packaging for you. For outer packaging, you can choose single boxes, neutral white boxes, color boxes, kraft boxes, or corrugated cartons. We can print your logo, product name, size, company info, warning signs, and instructions.

For inner packaging, we use bubble bags, foam, or EPE to protect the ball valve. It prevents collision, scratches, and moisture during shipping and storage.

We also provide export-standard packaging for sea, air, LCL, and FCL. It’s moisture-proof, pressure-resistant, and stacks steadily.

For long-term OEM/ODM customers, we save your packaging design. Later orders can use it directly, keeping your brand image consistent.

Whether you need simple logo printing, text changes, or full custom packaging,we cooperate efficiently and control quality strictly. We help you with product promotion and delivery.

7. Why should dealers choose Plumbersatr?

Plumberstar believes in long-term win-win cooperation. We focus on building stable, sustainable partnerships with distributors.

We don’t do one-time business. We never cut corners, use inferior materials, or change prices at will. We use stable quality, stable prices, and stable service to grow with you.

With our own production lines and large-scale manufacturing, we buy raw materials in bulk and optimize production. This keeps costs reasonable and gives you competitive agent prices.

When raw material prices go up and down,we first protect prices or lock them for long-term distributors. This ensures your profit and makes you more competitive.

For supply and delivery,we have fast response and stable production plans. We arrange production and shipment quickly. Urgent orders and restocks get priority. avoid out-of-stock losses and project delays. We keep supply and delivery on time.

For market support, we provide full promotion materials: HD pictures, product parameters, CAD drawings, material reports, certificates, and manuals.

We also support one-stop OEM: logo, packaging, and manual customization. We help you build your own brand, look more professional, and win customer trust.