What is the Strainer

A strainer is typically a simple, coarse mesh or perforated screen that removes large particles or debris from a fluid. For example, a kitchen strainer might remove seeds or pulp from fruit juice. A plumbing system might use a strainer to prevent large debris particles from clogging pipes or valves. Strainers are often used to protect downstream equipment such as pumps, valves, and meters.

What is the Filter

On the other hand, a filter is a more complex device designed to remove smaller particles and a more comprehensive range of contaminants from a fluid. Filters can utilize various media types, including activated carbon, ceramic, or membranes, to remove impurities. Filters are commonly used in water treatment, HVAC, and industrial processes to remove contaminants and improve fluid quality.

Note: Although there is some overlap between the functions of filters and strainers, the terms are often used to describe different types of devices with varying applications.

Strainer Vs. Filter: What is the Difference

How Does the Filter Work?

The operation of a filter depends on its design and the type of media used. However, a filter generally passes fluid through a medium that traps or removes impurities.

For example, consider a primary water filter using activated carbon. Activated carbon filters attract and adsorb impurities, including chlorine, volatile organic compounds (VOCs), and sediment. When water passes through the activated carbon filter medium, the contaminants are attracted to the surface of the carbon and become trapped.

As the filter medium becomes saturated with impurities over time, the filter’s effectiveness will gradually decrease. To maintain the filter’s effectiveness, the filter medium must be replaced or cleaned periodically.

Other filters, such as reverse osmosis filters, use a semi-permeable membrane to eliminate a wide range of contaminants, including dissolved salts, minerals, and heavy metals. These filters apply pressure to the fluid, forcing it through the membrane, trapping the impurities, and allowing clean water to pass through.

How do Strainers Work?

Strainers block larger particles or debris from passing through a system or entering downstream equipment. They are typically designed with a coarse mesh or perforated screen sized to capture the larger particles while allowing the fluid to pass through.

For example, in a plumbing system, a strainer may be installed in a water line to prevent larger particles of debris, such as rust or sand, from entering the piping and causing damage to downstream equipment, including valves, meters, or pumps. The strainer will typically be designed with a mesh or screen sized to capture the expected particles without significantly impeding the flow of water.

The effectiveness of a strainer depends on its design, the size and shape of the particles being captured, and the flow rate of the fluid. Over time, a strainer can become clogged with captured debris, reducing its effectiveness and increasing the pressure drop across the strainer. However, to maintain the strainer’s effectiveness, it must be cleaned or replaced periodically.

Strainer Mesh Guide

| Mesh Size | Micron Rating | Gap Size mm | Gap Size inch |

| 20 Mesh | 740 microns | 0.74 mm | 0.030 in |

| 30 Mesh | 500 microns | 0.50 mm | 0.020 in |

| 40 Mesh | 400 microns | 0.40 mm | 0.015 in |

| 60 Mesh | 250 microns | 0.25 mm | 0.010 in |

| 80 Mesh | 200 microns | 0.20 mm | 0.008 in |

| 100 Mesh | 150 microns | 0.15 mm | 0.006 in |

| 120 Mesh | 125 microns | 0.125 mm | 0.005 in |

| 150 Mesh | 100 microns | 0.10 mm | 0.0039 in |

Filter Design Construction

Filters are designed to remove particles and contaminants from a fluid by catching them within a filter media. Filters can be constructed in several ways, but the most common types include:

Cartridge filters: These cylindrical filters use filter media to capture particles as the fluid passes through them. Cartridge filters are often used in home water filtering systems. They can be made of paper, fabric, activated carbon, or other materials.

Bag filters utilize a filter medium, such as a bag, to capture particles as the fluid passes through them. Bag screens are often used in factories and can be made of either nylon or polyester.

Membrane filters utilize a semipermeable barrier to prevent particles from entering a liquid. Membrane filters are often used to purify water and in the pharmaceutical and biotechnology industries.

Strainer Design Construction

Strainers, conversely, are designed to remove larger particles or debris from a fluid by physically blocking them from passing through. Strainers can be constructed in several ways, but the most common types include:

- Y-strainers: These are strainers that are shaped like a Y and are typically installed in a pipeline to remove debris before it reaches downstream equipment. Y-strainers are commonly made of stainless steel, bronze, or plastic materials.

| Size | Length | Height | Kg |

| ¼” | 48 | 33 | 0.1 |

| ¼” | 48 | 33 | 0.12 |

| 3/8″ | 52 | 34 | 0.13 |

| ½” | 63 | 42 | 0.2 |

| 3/4″ | 75 | 50 | 0.28 |

| 1 ¼ | 91 | 63 | 0.56 |

| 1 ½ | 102 | 70 | 0.68 |

| 1″ | 118 | 87 | 1.33 |

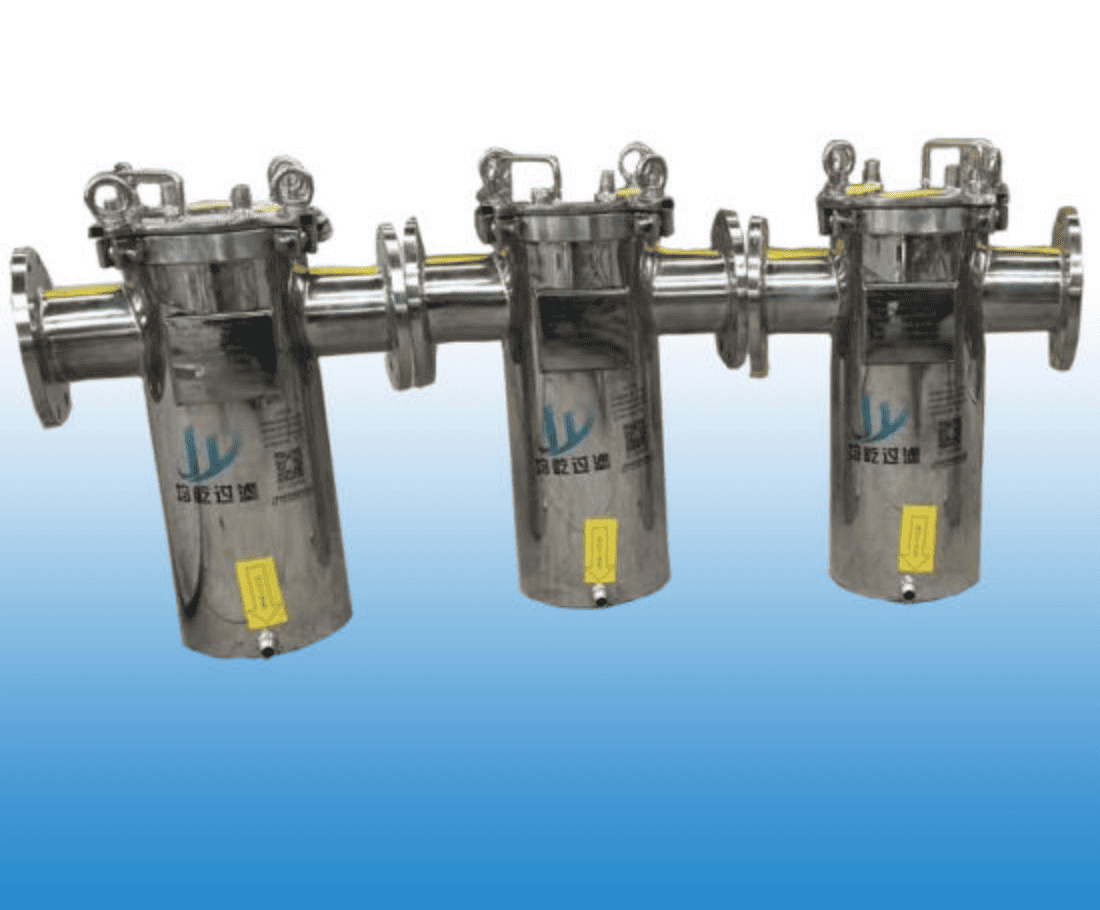

- Basket strainers: This type of strainer uses a basket-shaped screen to capture debris as the fluid passes through it. Basket strainers are commonly used in industrial applications, particularly in the chemical, oil, and gas industries.

- T-strainers: These are strainers that are shaped like a T and are typically installed in a pipeline to remove debris before it reaches downstream equipment. T-strainers are commonly made of stainless steel, bronze, or plastic materials.

- Duplex strainers:

These strainers have two parallel strainer bodies and are commonly used in applications where continuous flow is critical.

- Inline strainers: These strainers are designed for direct installation in a pipeline and are commonly used in applications with higher flow rates.

Strainer vs. Filter: Material

The material used in strainers and filters is crucial, as it can significantly impact the device’s effectiveness and durability. The choice of material can vary depending on the type of fluid being filtered or strained, the system’s operating conditions, and other factors.

Filters can be made from a variety of materials, including:

Cloth: Cloth filters are versatile and can be used to filter both air and liquids. They may store a lot of dust and dirt, and can be used more than once.

Filters composed of metal mesh are commonly used in the chemical and petrochemical industries, where high temperatures and pressures are prevalent. They have a long lifespan and can continue working regardless of the harsh conditions.

Porous ceramics are used as filters for high-temperature applications, where gases and liquids need to be filtered. They are highly stable at high temperatures and can operate effectively under harsh conditions.

Strainers Material

Stainless steel: The best stainless steel is known for its long-lasting and corrosion-resistant properties. This makes them perfect for use with acidic or corrosive fluids.

Bronze: Strainers made of bronze, commonly used in marine applications because of their resistance to seawater, are another popular choice.

Plastic: Plastic strainers are frequently employed in the pharmaceutical and food industries due to their high level of chemical resistance.

Filter vs. Strainer: Lifespan

Because they are designed to capture smaller particulates and offer a higher level of filtration, filters typically have a longer lifespan than strainers. The filter has a lifespan of 3 to 5 years. For instance, disposable paper filters usually need to be replaced every few weeks, whereas reusable metal mesh filters can last for many years with proper care.

Strainers have a shorter lifecycle than filters because they are designed to capture larger particles and are less effective at removing smaller ones. The average lifespan of a strainer is 2-3 years. A basket strainer may only last a few months in a high-flow application. However, with appropriate maintenance, the Y-strainer can last for years.

Filter vs. Strainer: Application

Filters and strainers are used in various applications to remove particles from fluids. Still, they are often used in different contexts depending on the fluid’s nature and the application’s specific requirements.

Filter Applications

When a high level of particle removal is necessary or when the particles are too fine to be removed with a strainer, filters are often used. Filters are used in many different environments.

Filters are widely employed in municipal water treatment plants to remove sediment and other impurities from the water supply before it is distributed to residents.

Filters are used in engines, hydraulic systems, and other industrial equipment to filter trash and particles from fluids, protecting the equipment from harm and extending its lifespan. Air purifiers and heating, ventilation, and air conditioning (HVAC) systems utilize filters to clean and improve the air quality.

Strainer Application:

Strainers are commonly utilized when the particles to be removed are large enough to be captured by a mesh or screen. Strainers are frequently used for;

- One common purpose of strainers is to prevent pumps from becoming clogged by dirt and other large particles.

- To filter out detritus, strainers are frequently installed in the water intake systems of cooling towers, condensers, and other industrial machinery.

Factors to Consider When Selecting a Strainer or Filter

When selecting a quality strainer and filter, several key factors must be considered to ensure the device is effective and suitable for your specific application. Here are some of the most vital factors to consider:

Type of Fluid: The fluid being filtered or strained is a critical consideration. Different fluids can have different properties that can affect the choice of a strainer or filter. For example, if the fluid is corrosive, the strainer or filter must be made from a material that can withstand the corrosive environment.

Flow Rate: The device must handle the required flow rate without causing significant pressure drop or flow restriction.

Particle Size: If the particles are tiny, a filter with a smaller pore size may be required. A larger mesh or screen strainer may be sufficient if the particles are larger in size.

Pressure Drop: The pressure drop across the strainer or filter is a crucial consideration, as it can significantly impact the flow rate and efficiency of the system. A strainer or filter with a high-pressure drop may require a more powerful pump or compressor to maintain the required flow rate.

Operating Conditions: The system’s operating conditions, including temperature, pressure, and humidity, can also influence the selection of a strainer or filter. The device must operate effectively and safely under the expected conditions.

Maintenance: The maintenance requirements of the strainer or filter should also be taken into consideration. Some devices may require frequent cleaning or replacement of filter media, while others may be more maintenance-free.

Filter vs. strainers: Why do they fail?

Depending on the application and operating conditions, filters and strainers may fail for numerous reasons. Among the most common causes of failure are:

The most frequent cause of filter and strainer failure is clogging, which occurs when the filter media or mesh becomes clogged with particulate matter. This can impact the system’s overall efficacy by reducing the flow rate and increasing the pressure drop across the device.

Bypassing is another cause of failure, which occurs when fluid can bypass the filter or strainer due to a faulty seal or a damaged component. This may cause unfiltered or unstrained fluid to pass through the system, resulting in equipment damage or system failure.

Physical damage, such as cracks or breaches in the housing, mesh, or media, can also cause the failure of both filters and strainers. This may be the result of corrosion or other factors.

Filters and strainers are susceptible to failure if overloaded with particles or residue that exceeds their capacity. This may result in device injury or a decrease in flow rate.

Chemical attack: Filters and strainers can fail when exposed to compounds incompatible with the device’s material. This may result in corrosion, deterioration, or other types of device damage. To prevent failure, it is crucial to select the appropriate type of filter or strainer for the application and to ensure that it is properly installed, maintained, and replaced as necessary. It is also essential to monitor the device’s performance regularly to detect any signs of clogging, damage, or other issues before they lead to system failure.