Nowadays, the valve is the key device for automation. Among the valves, the electric ball valve is user-friendly & works smoothly. Electric ball valves consist of an actuator & motor. The motor helps to make torque. Then, the valves can open in 4 to 5 seconds. The actuator needs 24-volt AC/DC or 230 volt AC power to function.

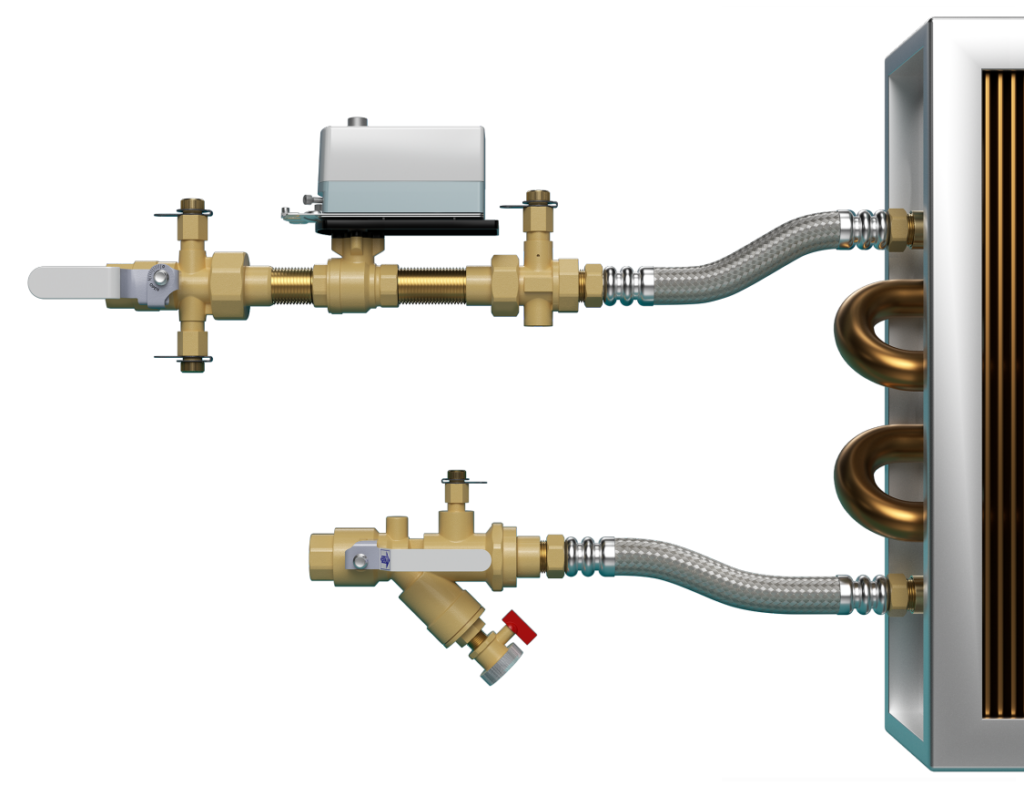

AC/DC Motorized ball valve has greater use in heating, ventilation, air conditioning, and firework. These valves are convenient for remote flow control applications & suitable for liquids and gases and often used in heating systems. Generally, the valve body is made of brass. The ball is chrome plated, and the seal is made of Teflon.

24-volt AC/DC or 230 volt AC valves are three types. Quarter-turn valve, Multi-turn valve & linear type valve. The quarter-turn valve has a 90° turn to open and close a port. Opening and closing the ports to ensure accurate fluid movement is more important.

From Joyfay International

In the heart of every modern plumbing system lies a mechanism that diligently guides the flow of water, ensuring a harmonious interaction between man and the liquid asset. But what orchestrates this seamless operation? Could the mystery conductor be the much-talked-about AC/DC Electric Ball Valve?

AC/DC Electric Ball Valves are the unsung heroes in the fluid control realm, orchestrating an efficient flow or shutoff of liquid or gas in a system. Their versatility in operating power source, alternating current (AC) or direct current (DC), makes them a valuable asset in various plumbing configurations, especially in a world leaning towards energy efficiency and operational effectiveness.

Engrossed? The world of AC/DC Electric Ball Valves is as complex as it is fascinating.

Why the Buzz Around AC and DC Operation?

The flexibility in the operation of power sources is a monumental stride in the fluid control industry. AC/DC Electric Ball Valves offer a unique proposition: the ability to operate under alternating current (AC) or direct current (DC). But why does this matter?

- Versatility: Being able to function in either AC or DC-powered environments opens up a myriad of application possibilities. This versatility is not only a testament to its adaptability but also its reliability in various operational settings.

- Energy Efficiency: The debate on energy efficiency has long raged on, but with the flexibility offered by these valves, optimizing energy usage based on the available power source is now a reality.

- Cost-effectiveness: Over time, the operational cost savings accrued due to the flexibility in energy sources can be significant, especially in large-scale industrial applications.

How Do They Fit Into Modern Plumbing Systems?

Plumberstar, a forerunner in offering bespoke valve and pipe fitting solutions, has always been at the cusp of leveraging modern technology to provide superior products. The inclusion of AC/DC Electric Ball Valves in their product lineup is a testament to their commitment to delivering innovative and high-quality solutions to their clientele, who range from wholesalers to factories dealing in mechanical equipment and hardware.

- Customization: The demand for tailor-made solutions is at an all-time high. AC/DC Electric Ball Valves can be customized to meet the specific needs of individual projects, ensuring high customer satisfaction.

- Quality Assurance: With free product testing and 100% product pressure testing, the quality of these valves is unquestionable, aligning with Plumberstar’s ethos of quality assurance and excellent service.

- Bulk Order Handling: The ability of AC/DC Electric Ball Valves to be reliably used in large quantities, without a dip in performance makes them an ideal choice for bulk orders.

How Does The International Market Perceive This Innovation?

The international market, especially countries like the United States, Germany, and Australia, have been receptive to the innovation brought about by AC/DC Electric Ball Valves. The blend of customization, quality assurance, and the ability to handle bulk orders has resonated well with overseas clients, mirroring the operational excellence they seek.

The narrative of David, a 50-year-old business owner from New Zealand who values high-quality, customizable products and good service, paints a picture of the international market’s demands. The AC/DC Electric Ball Valve stands as a solution to these demands, embodying operational efficiency and reliability.

Is This The Future Of Fluid Control Systems?

The journey of plumbing systems has seen the fusion of innovation and practicality, with AC/DC Electric Ball Valves being at the forefront. As Plumberstar continues to entrench its footprint on the global stage, the role of these valves in modern plumbing solutions cannot be overstated.

The marriage between flexibility, energy efficiency, and operational effectiveness encapsulated in the AC/DC Electric Ball Valves heralds a future where fluid control systems are reliable and in tune with modern energy efficiency demands and operational flexibility.

The tale of AC/DC Electric Ball Valves is a narrative of innovation meeting practicality, a scenario that not only benefits the industry but also sets a new standard in fluid control solutions. As the plumbing world continues to evolve, staying at the forefront of such technological innovations will drive operational efficiency and significantly impact the bottom line.

Applications & benefits of Motorized Ball Valve

The applications of AC/DC Electric Ball Valves are as diverse as they are revolutionary, affirming their place in modern fluid control systems. These valves, with their dual power source adaptability, are ushering a realm of possibilities across a myriad of sectors. Let’s delve into the tangible domains where these valves are making a significant imprint.

Industrial Automation:

- Process Control: In industries where fluid flow control is crucial, such as in chemical or food & beverage processing, these valves demonstrate their essence by ensuring precise control over process parameters.

- Water Treatment Plants: Facilitating the regulation of water flow within treatment plants, ensuring the effective treatment and management of water.

Building Automation:

- HVAC Systems: The role of these valves in Heating, Ventilation, and Air Conditioning systems is irrefutable. They aid in the efficient management of coolant flow, directly impacting energy efficiency and operational efficacy.

- Fire Suppression Systems: In scenarios of fire emergencies, having a reliable valve system is paramount. AC/DC Electric Ball Valves ensure a quick response in directing water where it’s needed most.

Marine and Offshore Applications:

- Ballast Systems: Managing ballast water in ships is a critical operation; these valves provide the necessary control to ensure the stability of vessels.

- Fuel Systems: They facilitate the precise control of fuel flow, directly influencing operational efficiency and safety.

Agricultural Automation:

- Irrigation Systems: Modern-day irrigation systems demand a level of automation that necessitates the use of reliable valves like the AC/DC Electric Ball Valves for effective water management.

- Pesticide and Fertilizer Distribution: Ensuring an evenly distributed flow of pesticides and fertilizers is crucial for modern agricultural practices. These valves offer the control required to achieve this feat.

Residential Applications:

- Home Water Management Systems: From managing the water flow to ensuring a properly functioning heating system, these valves find their application in various residential scenarios.

- Swimming Pool Systems: They assist in maintaining the desired flow and pressure in swimming pool plumbing systems, ensuring the water remains clean and fresh.

Each of these applications portrays the versatility and reliability of AC/DC Electric Ball Valves, echoing Plumberstar’s commitment to providing high-quality, customizable solutions to a broad spectrum of clients. The AC/DC Electric Ball Valves are not just a product; they are a representation of modern-day innovation tailored to meet real-world demands, ensuring the smooth operation of fluid control systems across various spheres of life.

· 24 24-volt or 230-volt electric ball valve is smart in shape.

· It can perform reliably.

· Long product life & easy to install.

· Good substitution for the solenoid valve.

· Applicable in moisture conditions.

· Vastly used in vacuum applications and irrigation equipment.

· Frequently used in drinking water equipment & industry.

· Good for use in the latest technology like gravity feed, low pressure, solar water heaters

· Applicable in households like washing machines and water heaters.

· Greater flow capacity

· Reasonable price

· Sustainable service life.

· Anti-water hammer.

Installation And Wiring Of AC/DC Motorized Ball Valve

A Motorized electric ball valve is an automatic control solution. Any voltage ranges are applicable for this. Low voltage wiring with 24 volts DC/AC actuator is widely used & a good option. It is preferable to use 230 volt AC. In this case, expense, ease of wiring, and distance are the issues. There are three wires, blue, brown & black, in the actuator. The Blue one is negative or neutral. Black and Brown’s wires are positive. The Black one is for controlling purposes.

Sometimes an electric on-off function may fail. You can run the valve in a manual process. But replacing the faulty actuator is the best solution. Valves can open or close in a manual process.

The actuator is always set up on top of the valve. It can be removed and remounted in a very easy way. Maintenance is also flexible if necessary. Setting up a 24-volt electric valve with an actuator is time-saving. We can replace the actuator only for this time.

Proper connection of 3 wires is very important for valve operation. The blue wire connects with the 24-volt transformer’s neutral connection. The Brown wire connects with the 24-volt transformer’s line connection. The black wire connects with the 24-volt transformer’s line connection.

The valve will open when the switch connection is finished. It means connecting the black wire and the 24-volt transformer line. The valve will close when the switch connection is not completed. It is the connection between the black wire and the transformer. Wiring the actuator needs a few components & parts. These are a power source, a power strip with many outlets, a regular light switch, and a 24-volt transformer. A low-voltage wire, a three-wire bundle, wire nuts, or other wires connections are also needed. If you have connections exposed to water, you need waterproof parts.

From Assured Automation

The actuator’s blue wire should be joined to the neutral of the transformer. Brown wire should be joined to the line connection of the transformer. The black wire should be joined to the light switch.

We can test the actuator’s performance by opening and closing the valve. First, plug the 24-volt transformer into the outlet. Then flip the switch off of the valve. This time, the actuator turns the valve stem to 90 degrees of the flow direction. You should look through & verify whether the valve is closed or not. The valve will be in a compact state.

Now time to check the open valve condition. Flip the switch to open the valve. Then, the actuator turns the valve stem parallel to the valve body. We should look through & verify whether the valve is open or not. The valve will be in a relaxed state.

Before starting the whole system, this type of checking is necessary. It will save time. After checking these, you can connect the valve to the system. It should function well. It is another important thing to keep in mind about the power outage situation. When power loss happens, the current state of the valve will remain the same. At the time of power restoration, it will not change itself.

Operation of 24 volts or 230-volt valve

9 to 24-volt AC/ DC & 110 to 230 volt AC Motorized ball valves are used frequently. These vales allow any flow. The flow in full gear is not an issue. This is why electric ball valves perform better than solenoid valves.

After turning on the power, the valve opens fully. It charges the internal capacitor also. A tiny amount of energy can maintain the charge of the capacitor. If power loss happens, the capacitor’s charge can proceed to close the valve. This is very much electrical & mechanical error-free for 24 volt AC/DC or 230 volt AC. Electric ball valves are always bi-directional, so media can flow in either direction.

These AC/DC valves can eliminate water hammers because they have slow response times. Few actuators are weather-resistant. We have to use caution when installing them outdoors. It is recommended that the valve be installed with the actuator up. It is necessary for a high degree of vibration.

An ideal 230-volt AC Motorized ball valve is nearly 2 to 5 inches in size. It operates at around 10 bar pressure. The Rated current is 50 to 140 mA. The output torque is near 22NM. The actuator rotation is 90 degrees.

For household or industry purposes, these valves are used widely. These make our life easier & comfortable.