The use of motorized valves reduces the hassle required to operate the valves manually. Motorized Ball Valves are the most popular and widely used among the different types of valves. Motorized ball valves are versatile devices used in a wide range of applications across various industries. They offer precise control over fluid flow and are commonly used for both on/off and modulating functions. That is why we have come to share the secrets with you to put them to good use.

Motorized Ball Valves Uses

For applications requiring continuous automatic flow control… motorized ball valves are the best option. You can use them anywhere in your home where you need automatic water control—for example, home water systems, HVAC, water filters, and other automation projects.

And if you come to its industrial uses, you cannot finish the application count. Some examples are water treatment equipment, chemical oil applications, vehicle wash systems, food processing, fire fighting systems, industrial compressors, manufacturing facilities, and so on. These valves are suitable for almost every job. However, choosing the right type for your needs would be best. Also, there are some rules to follow to use them properly.

- HVAC Systems: Motorized ball valves play a crucial role in heating, ventilation, and air conditioning systems. They control the flow of hot or cold water, glycol, or other heat transfer fluids, regulating the temperature in buildings. These valves are essential for zone control, ensuring that different areas receive the right amount of heating or cooling.

- Industrial Processes: In industrial settings, motorized ball valves are used for process control. They can handle a variety of fluids, including water, chemicals, and gases. Industries such as manufacturing, chemical processing, and food production rely on motorized ball valves to control their processes precisely.

- Water Treatment: Water treatment facilities use motorized ball valves to manage the flow of water, chemicals, and additives. These valves ensure that water is treated, filtered, and distributed properly, meeting the required quality standards.

- Irrigation Systems: In agriculture and landscaping, motorized ball valves are used in automated irrigation systems. They control water flow to different zones, helping conserve water and ensure that plants receive the right amount of hydration.

- Swimming Pools and Spas: Motorized ball valves regulate water flow in swimming pool and spa systems. They are used to direct water to different features like fountains, jets, and waterfalls, enhancing the recreational experience.

- Plumbing Systems: In residential and commercial plumbing, motorized ball valves can control water flow in individual fixtures, such as faucets and showers. They are also used for whole-house shutoff valves to control water supply to a building.

- Fire Protection Systems: Fire protection systems often use motorized ball valves to control the flow of water or fire-suppressing agents. These valves play a critical role in fire sprinkler systems, ensuring water is delivered to the appropriate areas during a fire emergency.

- Oil and Gas Industry: Motorized ball valves are used to control the flow of oil, natural gas, and other hydrocarbons in pipelines and processing facilities. They provide reliable shutoff and control in demanding and hazardous environments.

- Marine Applications: In marine systems, motorized ball valves control water and fluid flow for various purposes, such as ballast systems, bilge pumps, and engine cooling.

- Brewing and Beverage Industry: Breweries and beverage production facilities use motorized ball valves to control the flow of liquids during the brewing and bottling processes, ensuring precise measurements and consistent product quality.

- Chemical Industry: Motorized ball valves are used for precise control in the chemical industry, handling a wide range of corrosive and hazardous substances.

Motorized ball valves offer advantages like fast response times, tight shutoff, and remote control capabilities. They are vital in systems where precise control, reliability, and automation are essential. Their applications are diverse, making them a critical part of various industries and systems.

Motorized Ball Valves About

In order to use the motorized ball valves in the right way and in the right place, you need to know them.

What Is A Motorized Ball Valve?

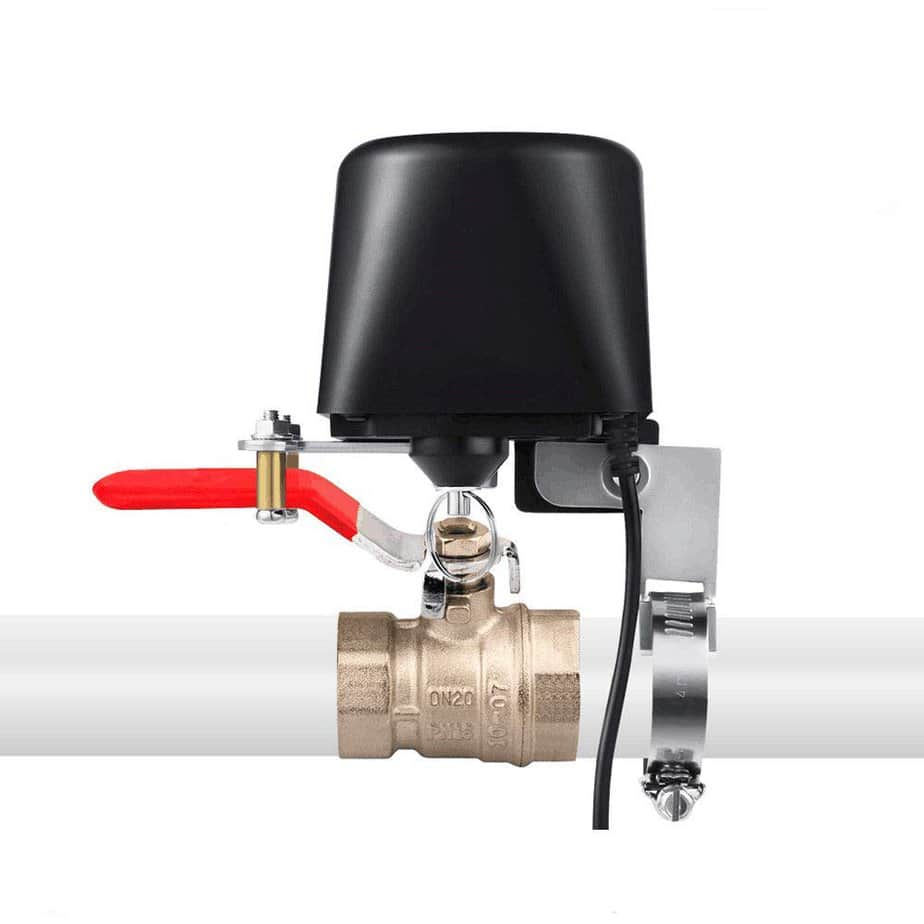

The Motorized Ball valve is an automated ball valve that uses a motor to control its mechanism. It is an integrated valve consisting of a ball valve and a motor that automatically opens and closes by energizing the motor after receiving an electric signal. Thus, it is also known as an Actuated ball valve.

Parts

You can break down a motorized ball valve into two separate parts. Those are a ball Valve Body and an Electric Motor.

The valve body is a standard ball valve. It has a steel ball with a bore at its center. It is called the rotary ball. In addition, two-valve seats surround the ball from either side. Therefore, the ball can sit properly inside the valve body and rotate without any interruption. Also, a small metal rod called steam… attaches to the ball from one end and connects the ball to the motor from the other end.

For motorized valves, the ports of the ball valve come in two variants: two ports or three ports. The two-way or two-port valves have one inlet and one outlet. The three-way valves have two inlets and one outlet or vice-versa. So you can use them any way you want.

On the other hand, the motorized part consists of a motor and an electric circuit. This is where the steam connects the ball with the motor. Also, you will see two wires outside of this part. These wires are used to supply the electric signals to the valve. Finally, a plastic cover covers the whole motorized part. Sometimes, you will see an indicator and a manual switch in some motorized ball valves outside the plastic cover.

Working Procedure

The motorized ball valves are operated by the motor that follows the electrical signals. These valves have two types of initial states: generally close and normally open.

For example, your valve is the normally closed one. When it receives the signal, the motor will start energizing. After gaining enough energy, the motor or the actuator will start rotating. Since it is a quarter-turn actuator, it will rotate up to 90 degrees to open the valve. Therefore, the ball will also start rotating, and the bore will meet the valve ports to allow media flow. Further, the reverse is true for the normally open valves.

One more important thing you should keep in mind is the indicator. If your motorized valve has an indicator, then you will see a straight line on the indicator. Remember, when the line is horizontal, it means the valve is open now. And it closes when the line is vertical.

Important Rules to Follow

· When installing motorized ball valves, be sure that it is in a horizontal position… and the part of the motor or actuator must be on top.

· The valves should not receive more than their capacity voltage. This will cause great damage to the actuator.

· In case of a power drop, you can operate the valve manually. But keep in mind that before doing this and before maintenance, make sure that the power source of the valve is off.

· Do regular checkups of the valves and ensure their functions are working well.

Buying Guide

Buying the motorized ball valves is not that hard when you know the right ways. Here is what you should follow when buying:

Ø You will see different types of materials for the ball valve body part. However, not all materials are appropriate for all uses. For example, stainless steel works well for food applications, and brass best fits industrial settings. So, think carefully, or you can take Expert Advice.

Ø If you buy the valves for your drinking water line or a food application, take the lead-free material.

Ø Keep in mind the valve running time and consider how much time you need. It can be anywhere from 3 to 25 seconds (depending on the manufacturer).

Ø As you already know, ball valves are available in different types and sizes. So, consider which types and what size you will need for your purpose.

Ø Last but not least, different motors require a different range of power to operate. Choose one that will work efficiently, even in low energy.

Moreover, you can check our motorized ball valves to buy premium quality valves at affordable prices. In our factory, you will find any valve. We also accept OEM and ODM to meet your unique requirements.

Benefits of Using Motorized Ball Valves

Here are some fantastic benefits of motorized ball valves that will inspire you to use them:

- Automated and efficient working.

- Minimal noise.

- Visual indicator.

- Suitable for all types of media and applications.

- Low power requirement and only needs power when moving the actuator.

- Pre-wired. No need to disassemble the valve during installation.

- Offers manual operation and easy installation.

In conclusion, motorized ball valves are used in nearly every application. All you have to do is use them properly and in the right place. We believe you can do it now if you have read the whole post. Good luck.