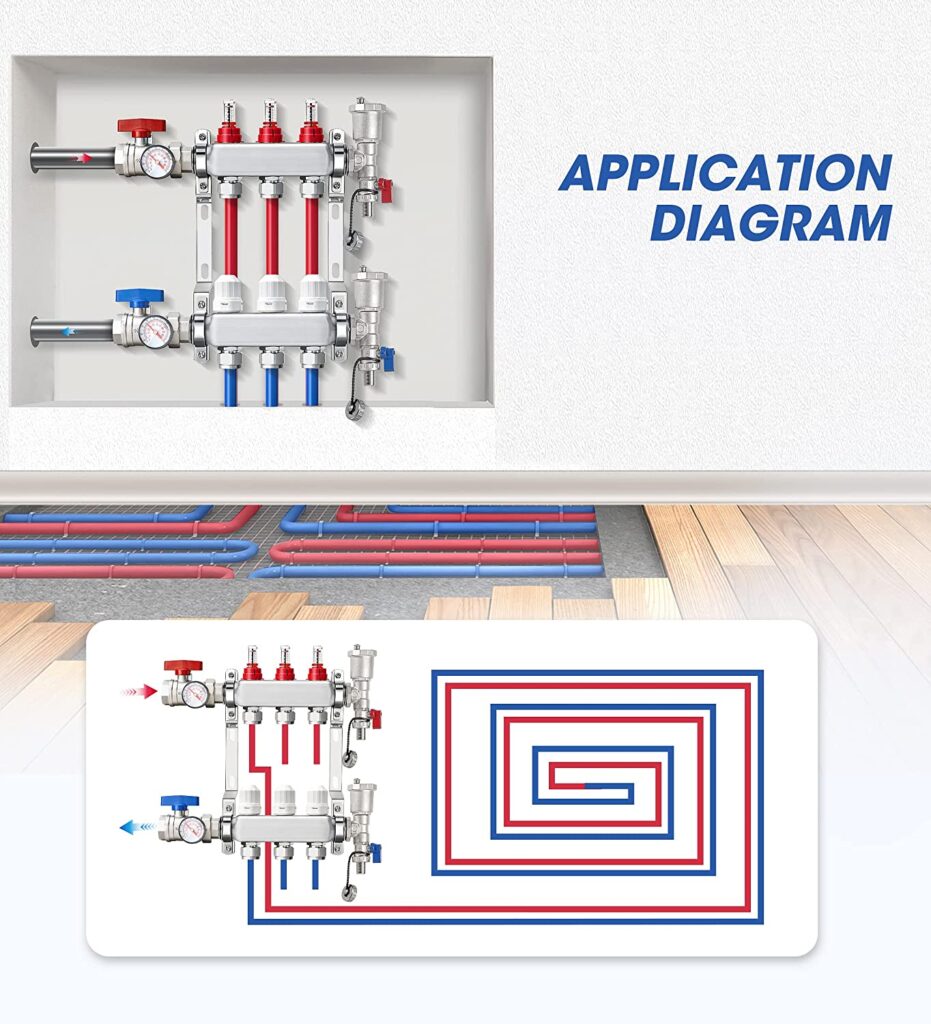

What is an underfloor heating manifold?

Are manifolds necessary for underfloor heating? Underfloor heating is two rows of taps that permit a stream. It splits the tube circuits that fix the distinct zones on the floor. With this help, the site or area remains in equilibrium and controlled conditions. Yet, the two rows have flexible valves with a small cover or cap about the size of a thimble. This thimble appears to indicate the stream rate via it. Yet, the valve turns the stream rate to decrease or increase.

It permits the framework to have the desired stream ratio in each circuit, yet if you have a 100m coil of tube installed below the floor in the kitchen, the separate 80m coil of the line in the dining room.

The pipes will reverse to the tap on the manifolds. The alterations ensured that there was the same stream in every zone. This is due to the diverse extent of the tube. There may also be a motor on the tap beneath the row. By this row, the area turns off when the heat is no longer needed in that zone.

Why are the PEX manifolds necessary for the heating system?

When it appears to be underfloor heating, it is not as simple as pumping hot water across the entire tube. Yet, you are expecting that all warm up as needed. The heat loss of the area where it moves affects the stream rate via every tube’s coil.

This means the framework must be in equilibrium to ensure the stream’s circulation is suitable. Yet, due to the difficulty of the condition, there will be distinct pipe length increases.

These heating manifolds act as the main center of the underfloor heating system. Yet, it is to describe the problems, ensuring an accurate stream of water to the pumps.

Yet it can do so in every area to warm it to the precise temperature set by the installer applying the supplied design material.

How do the underfloor heating manifolds work?

The underfloor heating manifolds are made of two rigid bar tubes. Each tube has a row of fixtures. You can have up to 12 taps on every rod. One rod has the water running to the area, while the other bar has the water moving reverse from the site. The manifold pump can run the water to the regions.

After the pump, the appliance permits water to pass through the manifold if many areas are off. A boiler requires a lower stream rate in the heating circuit, so some water is required to give the manifolds. Yet, the resistance is too high for many closed taps.

How to balance the underfloor heating system?

Change the stream meter to attain equilibrium. This will ensure that the stream rate distributed to every area is at the best level, giving consistent heat throughout the floor. The stream rate is required to alter the length in every loop. It is described in the tube installation manual and layout designs.

How to attach an underfloor heating pipe to the manifold

Ensure you cut the MLCP pipe square with a robust plastic line cutter. It is fundamental to open the inward bore of the line with a line reamer instrument. It prevents harm to the O-rings while embedding them into the monobloc fitting.

Implant the cable into the fixing association until it is home. Turn the nut until the checking opening matches the space in the grasping ring. Try to ensure that the bar is fixed as far as possible.

Tighten the nut onto the manifolds and fix it with a 27mm spanner without over-the-top energy. Hold the fitting with a spanner while fixing the pipe nut. It moves when the line links with the stream manifolds in pipe format.

Yet, it is associated more with comparing the return manifold link. Yet, it is currently an entire circuit. When all courses fit and fit, bring some margin to examine the pipework. Ensure the spacing is correct and there are no kinks in the line.

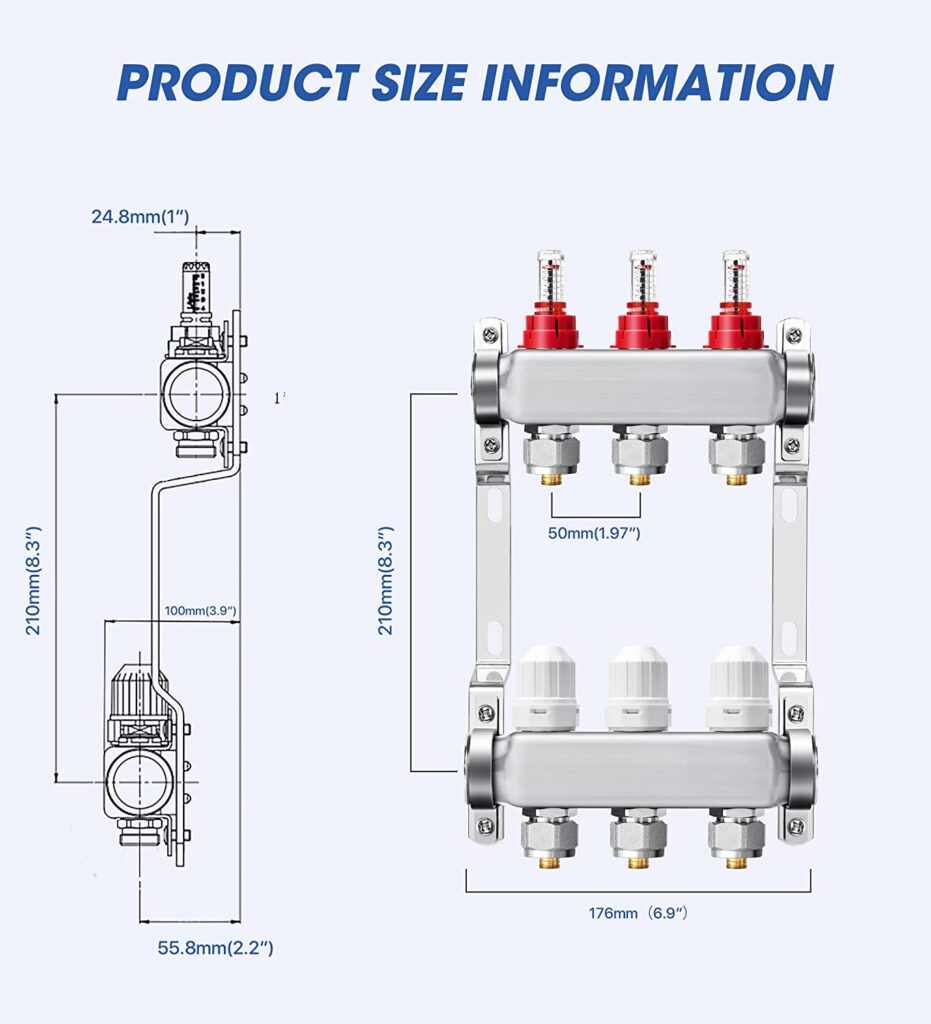

Dimensions and Ports

| Manifold Length (mm | No. of Ports |

| 192 | 2 |

| 242 | 3 |

| 292 | 4 |

| 342 | 5 |

| 392 | 6 |

| 442 | 7 |

| 492 | 8 |

| 542 | 9 |

| 592 | 10 |

| 642 | 11 |

| 692 | 12 |

Essential Parts of Underfloor Heating Manifolds

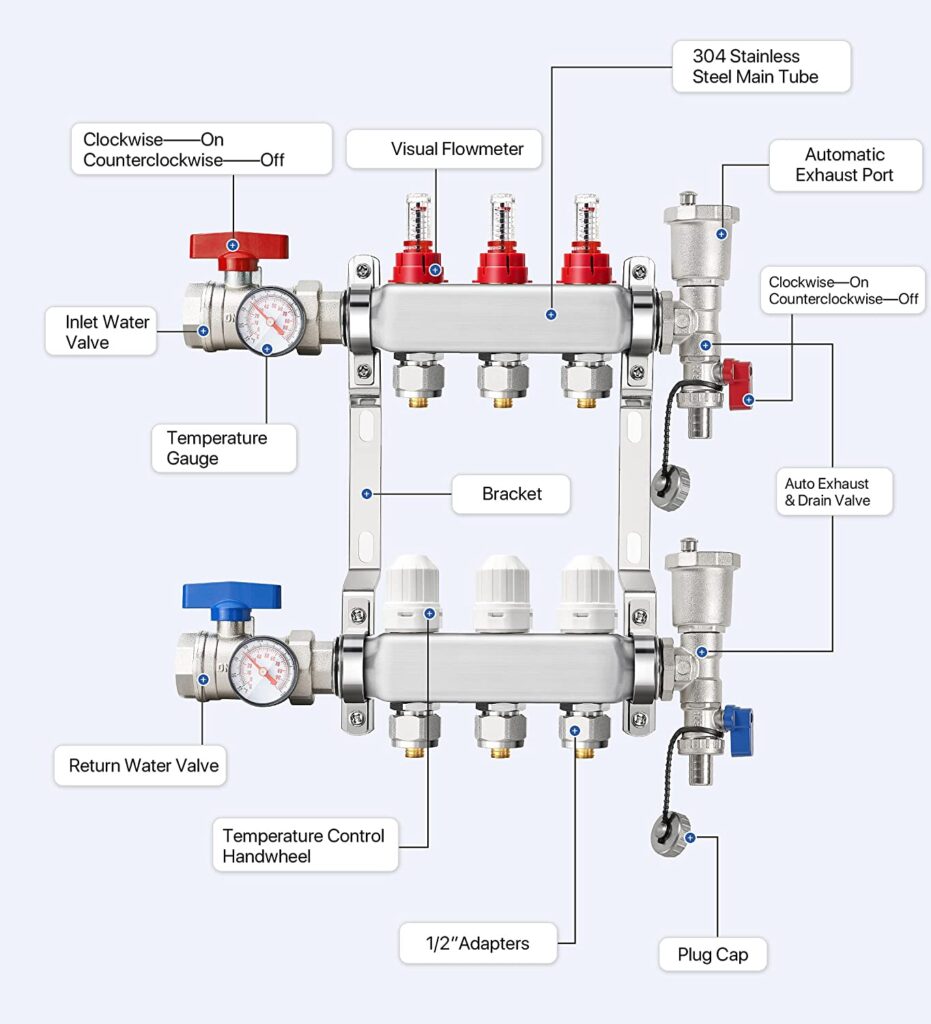

- Flow Temperature Device

The hot water feeds the stream manifold. The temperature will display on the flow temperature device.

- Drain or Filling Off Valve

The drain or filling-off valve is used to start filling and draining the underfloor heating system.

- Flow Gauge

This part of UFH displays the current stream rate for the area. It is set by applying the stream change valve. The desired stream rate circulates and is shown on a CAD drawing during the design.

- Flow Adjustment

This valve allows users to set the flow rate running through each circuit.

- Return Temperature Gauge:

It permits the differential temperature between the stream and returns to evaluation.

- Pressure Gauge

This pressure gauge is on the stream back manifold rod. It applies to assess the pressure in the pressure test.

- Manual Air Vent

It permits cutting off from the underfloor heating system.

- Main Isolating Valve

It applies to separating the manifolds during the first filling and servicing.

- Actuators

It plays a role as the gate, closing or opening to permit the water to stream through each circuit. Yet, it controls the corresponding area thermostat.

Types of UFH Manifolds

There are two main types of underfloor heating manifolds;

1) Stainless Steel Underfloor Heating Manifolds

This type of underfloor heating manifold includes return manifolds. It has a shut-off valve along with flow meters. Here are the properties of these underfloor heating manifolds.

- Stunning appearance

- Heat and fire resistance

- Corrosion resistance

- It has a distinct thermal expansion rate than brass.

2) Brass Underfloor Heating Manifolds

The Brass UFH manifold has no pump. Yet, they are fit for fitting with a heat pump framework. The flow can easily be read per set with the help of a flow meter. The upper rail is fitted with a thermostatic valve. The best quality brass is a good fit for cooling and UFH. They are;

· Stand with high-temperature

· Durable

· Less complex, so easy to install

· It builds the floor heating products more united.

How do you install the Pex underfloor heating manifolds?

Manifolds are distributed, prepared, and collected, and need mounting on sections before the fix. You can fix the manifold whenever you’ve laid your clip rails. Yet, checking the UFH framework intends to see the length and number of each loop required.

Step-1

The link with the manifold stream rail begins on one side of the manifold. Note which loop acts on the different tags provided.

Step-2

Spread the tube out, exploring the most effective route between the area and the manifold. Then, according to the framework plans, apply the line to the clip rail.

Step-3

On finishing the loop, follow a similar way back to the manifold and link with the return bar (base bar with blue covers). However, clearly note the actual loop length fix on the manifold tag.

Step-4

Track a similar process for all loops until the area is covered with a UFH pipe.

Step-5

The framework can be pressure-checked when all circles are fixed and associated with the manifold.

Note that the two manifold rails counterbalance. Yet, the lines can pass behind the lower bar for links with the main bar. I suggest applying the main line as the stream and the base bar as it moves back.

Where Should a Stainless Steel Underfloor Heating Manifold Be Set?

Underfloor heating manifolds can take up a lot of space, yet they must be available for service and inspection. Unlike your heating controls, they don’t need to be set for regular use.

Initially, the manifold must also be set where the distinct area pipes can all meet without overheating the floor.

The second attention is the nearness of the heat generator (boiler or heat pump) to the manifold. The further from the manifold the heat generator is, the greater the likelihood of heat loss. Yet, the pipes will be stiffer to weigh so that any heat loss does not clash with the heating circuits. Yet, it cracks or causes loss to the fabric of the construction.

The manifold is suitable for adding to a plant room if one is being made in a self-built home. Yet, for instance, this may depend on the layout and proximity of other technology, which is also essential in the room.

How to Consider Radiant Underfloor Heating Manifolds While Purchasing?

It is normal to assume a separate manifold for each property floor. Suppose you have underfloor heating down the stairs and radiators upstairs. In that case, you may not want a manifold for the radiator circuit if it is explored in a similar shape.

Suppose you select a manifold for the radiator circuit. In that case, the motorized controls will be isolated from the rooms, yet they do not interrupt anyone from being asleep. Assume the size of the radiators to work at the same flow temperature as the underfloor heating. In that case, it will likely connect radiators and underfloor heating circuits on the same manifold.

Still, caution must be taken to balance the system. The radiators could have less conflict than the underfloor heating circuits. Yet, to get the line to share the heat, it must exit the underfloor heating circuits and feel less than operational.

Underfloor heating has been around for a long time, but it is only recently that the general public has become alert to the profits that can be increased from such a system.

How to Specify an Underfloor Heating Manifold?

Underfloor heating manifolds are purchased separately from the other components of an UFH system. Still, you must ensure they are compatible with the pipework and all the different parts and controls. Some manifolds have fittings designed for a specific type of pipe and may not be compatible with other lines.

An accurate pass and mixing valve are also required if the temperature needs to be controlled or limited. Your installer should influence the design and ensure that the components work together.

How to adjust the underfloor heating manifold?

You must select the stream meter to set the stream rate of UFH manifolds. The flow meter turns them to decrease or increase the stream rate. Every loop on the stream rail has a flow meter. This meter will show the stream ratio in each loop. Yet, these loops apply to balance the framework at the appointing step.

Significant benefits of underfloor heating manifolds

- Better ease levels are due to a more consistent heat supply and a lower level where desired.

- Lower running costs as a consequence of improved efficiencies and the use of energy.

- The system needs cooler water than the radiators. This allows boilers to run more and creates heat sources such as solar, which are more viable for heating.

- Separate room temperature control is standard.

- Noiseless, with lower water velocities, air, and no creaking radiators.

- Cleaner, with no valves that can remove drenched carpets. There are no unseen spots behind radiators where dust and small substances collect.

- Vandal Resilient – no radiators are needed to walk out of the place.

- The material temperature of the building was kept.

- Free wall spaces. The underfloor system is inconspicuous, with no noticeable pipework. It permits walls to be magnified and furniture to be situated without fear of hiding radiators.

Disadvantages

The main disadvantages of existing buildings during fitting.

- It needs a long period to warm up and cool down. Cannot answer fast to rapid temperature deviations.

- The choice of floor finishing requires cautious concern as it may disturb the performance.

- If completed during the refurbishment phases or new build, fitting is straightforward.

Many time-saving pipework systems are now available to cover all floor types, from suspended timber floors to concrete screeds. Altering your house while living in it is possible, although very disruptive.

To simplify the installation of a current system, we need to set a range of units to cover all the framework variants we have yet uncovered.

Some Problems with Underfloor Heating Manifolds

Sometimes, the UFH framework does not operate as usual. Here are some issues with the underfloor heating.

Blockage in the system

The system must flush if the backup is due to a physical item, not by air. By cleaning the system, all the waste material will be removed.

from PEX Universe

Imbalance or Incorrect flow rate

These are set by applying the flow meter to the stream rail. The underfloor heating structure provides the accurate rate at which these adjust.

Air the system

To correct this, you must bleed the air off the framework. You can apply the air Vent on the steam rail of the manifolds.