Check valves are fixtures that let fluid flow in only one direction. Backflow prevention is a key feature of a check valve. Spring and Swing check valves are two crucial types of check valves. They prevent backflows in systems using different mechanisms as per their structure. Here is the difference between the swing and spring check valves.

Swing Check Valve:

The swing check valve allows or stops the flow of fluids by swinging a flapper. This mechanical device relies on the swinging motion of a flap or a hinged disc. The flapper turns away from the seat to allow the liquid, giving the fluids enough space to escape. For the valve to close, the flapper turns back towards the seat and blocks backflow.

The situation creates automatic valve closure on decreasing pressure in the system. The valve’s swinging operation enables it to bear a large flow capacity easily. At the same time, due to swing motion, these valves cannot perform well in horizontal or upward vertical conditions.

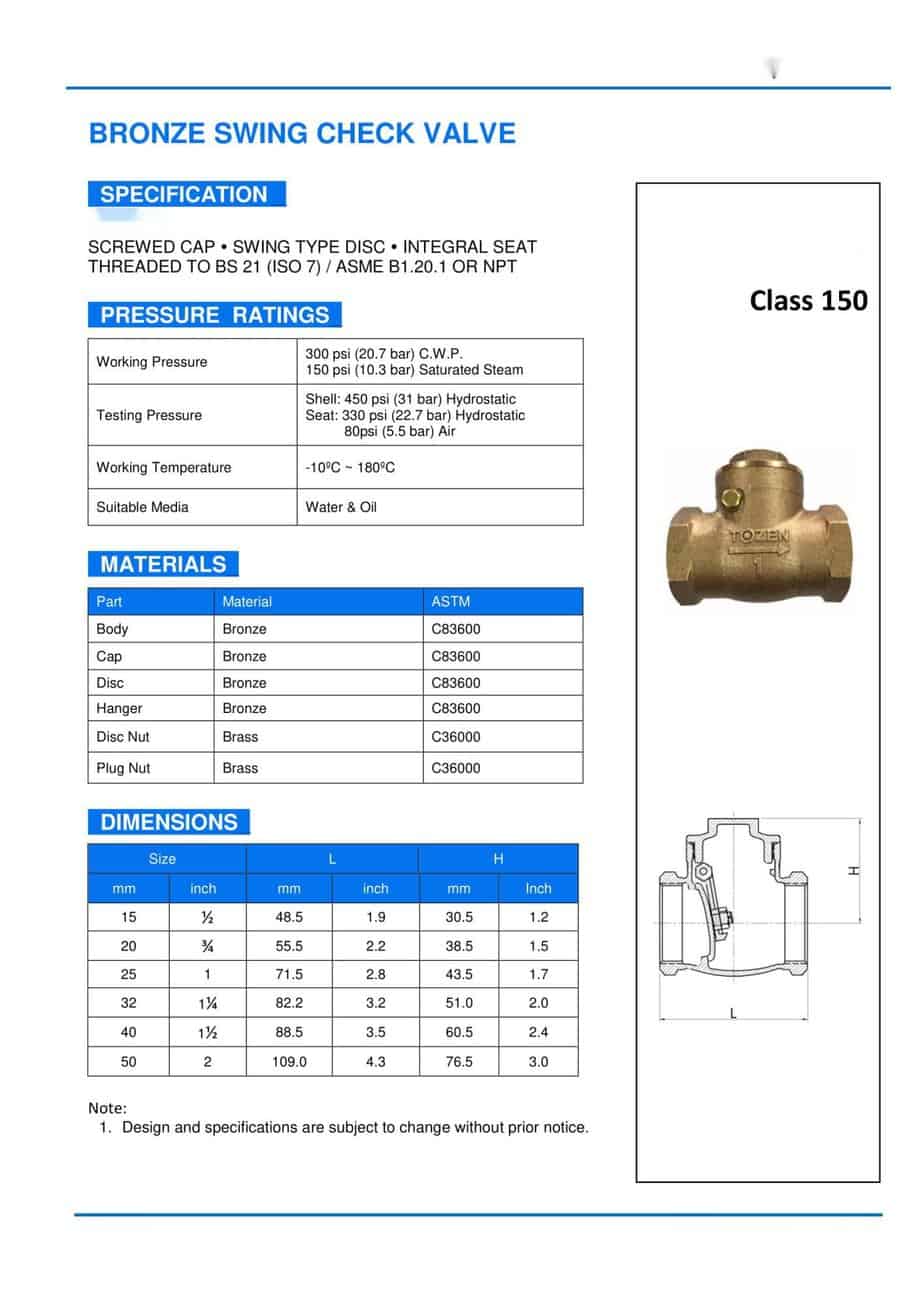

Specifications:

| Product Name | Brass Swing Check Valve |

| Size | 1/2 – 2 |

| Material | Lead-free brass |

| Finishing | Sand-blasted |

| Thread | BSP, NPT |

| Working Pressure | 200 Psi |

| Temperature | -15°C to 115°C |

| Medium | Water or Non-corrosive liquids. |

Swing Check Valves: Pros and Cons.

Swing Check valves have the following set of advantages and disadvantages.

Pros of Swing Check Valves:

●Moderate Flow Capacity:

Swing check valves are suitable for applications having moderate flow rates. This property also makes them adhere to variable flow in many systems.

●Minimum Clogging:

Swing check valves have the least risk of clogging among all check valves. This is because the swinging motion dislodges the debris and prevents blockage.

●Less Pressure Drop:

These check valves are best for applications where minimizing pressure loss is essential. They can perform far better than other check valves in such requirements.

●Low Cost:

Another advantage of swing check valves is their low cost. They give reliable performance within a very economical budget.

●Large Flow Capacity:

Spring check valves are excellent products to manage large flow capacities.

Cons of Spring Check Valves:

●Slow Closure:

Spring check valves do not offer quick closure like some check valves. It can lead to water hammering in conditions where immediate valve closure is necessary.

●Limited Reverse Flow Tolerance:

In case of high reverse flow pressure, swing check valves may not provide an effective seal. The disc gets limited at high pressure and can lead to leaks.

●Slamming:

As swing check valves are limited to high flow rates, they can be prone to slamming at high flow rates. Yet, this effect can be reduced by using a damping device.

Applications of Swing Check Valve:

A few applications of swing check valves are as follows.

Municipal System:

Swing check valves prevent flooding in the sewage system. They also block the backflow of gases and liquids through various channels in municipal systems. They also manage and avoid contamination from entering clean water.

Fire Protection System:

Swing check valves are suitable for use in water sprinklers within fire protection systems. They ensure no backflow occurs, as a fire-fighting equipment blockage can cause potential damage.

Marine Environment:

Swing check valves mark the effective working of ships by managing backflows. They prevent seawater and fuel from backflowing.

Industrial Processes:

Swing check valves are widespread in almost every industrial process. They block reverse chemical and other fluid flow in refineries and chemical plants.

Petrochemicals:

These valves are efficient in controlling various fluids in the petrochemical industry. Their primary function is to prevent mixing different chemicals and make processes go smoothly.

Spring Check Valve:

Spring check valves operate via a spring mechanism. They contain large stoppers in hollow bodies, actuated by spring pressure. When fluid flows forward at high pressure, it causes the spring to open. The situation arises when the force of fluid overcomes spring pressure. Thus, the path is open, and liquid can move across.

Specifications:

| Product Name | Water Spring Check Valve |

| Size | 1/2 -2, 1/2 -4 |

| Material | H583, CW617N, CW602N |

| Finishing | Sand-blasted |

| Threads | BSP, NPT |

| Working Pressure | 200 Psi |

| Spring | Stainless Steel |

| Temperature | -10°C TO 100°C |

Spring Check Valve: Pros and Cons.

Here is a list of the advantages and disadvantages of the Spring check valve.

Pros of Spring Check Valve:

●High Flow Rates:

Spring check valves can undertake high flow rates as they can handle large volumes.

●Quick Closure:

The spring in the valve offers efficient and quick closure in case of backflow. This property saves from hydraulic issues like water hammering.

●Flow Orientation:

Spring check valves are not limited to only vertical or horizontal flow. Instead, unlike swing check valves, they can manage fluid in any direction. They can also handle upward and downward flow because gravity does not influence the spring’s working.

●Versatile:

Spring check valves are among the most versatile check valves. Their design can be adaptable for multiple industries and suits many applications.

●Positive Sealing:

Spring provides the most reliable positive sealing in case of reverse flow. They also keep a check when the direction of backflow changes.

Cons of Spring Check Valve:

Spring Fatigue:

The spring in a check valve can be prone to fatigue over time. This can result in a reduced sealing capacity and poor valve efficiency.

Limited to Low-Flow:

Spring check valves are designed to accommodate high flow rates. Thus, they are limited to low-flow applications and may need to improve in these conditions.

Higher Maintenance:

The spring in the check valve takes more maintenance to keep working. They usually need more care and inspections than swing check valves.

Applications of Spring Check Valve:

Spring check valves can be applicable in the following industries.

Irrigation System:

In the agriculture field, spring check valves ensure a unidirectional water flow. It saves irrigation lines from contamination due to backflow.

- Aerospace:

Spring check valves are applicable in the aerospace industry to ensure the system’s safety. They prevent the backflow of hydraulic fluids and fuel.

- Automotive Industry:

In automobiles, spring check valves enable brake operation to be effective. They block the backflow of brake fluid.

- Residential Plumbing:

Residential plumbing systems use spring check valves on a large scale. They let fluid flow in one direction only in water supply lines and pumps, etc.

- Hydraulic Systems:

In various hydraulic systems, spring check valves regulate hydraulic fluids to ensure the safe operation of the system.

General Differences: Swing Check Valve vs. Spring Check Valve.

Here are some general differences between the swing and spring check valves.

| Property | Swing Check Valve | Spring Check Valve |

| Design | Compact Design | Bulkier design due to the spring |

| Closure Mechanism | Swing Disc or a Flap | Disc pushed by Spring |

| Closure Speed | Slow closure speed | Quick closure speed |

| Pressure Drop | Lower pressure drop | Moderate pressure drop |

| Range of Flow Rate | Suitable for low to moderate rates | Suitable for high-flow rate |

| Resistance to Clogging | Less prone to Clogging | Less prone to Clogging |

| Applications | Best suited for low- to moderate-flow rate applications. | Versatile and suitable for multiple applications. |

The Bottom Line:

Swing and spring check valves offer many features, making them a top choice for non-return valves. When selecting between spring check valves and swing check valves, consider application demands as your top priority. Plumberstar offers many reliable check valves curated to meet industry standards. Mark your requirements and get the most suitable check valve for your system.