Description

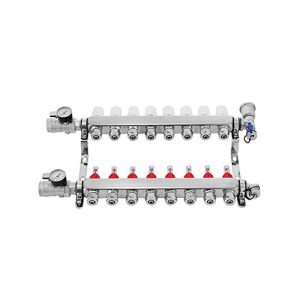

Water Distribution Heating Manifolds

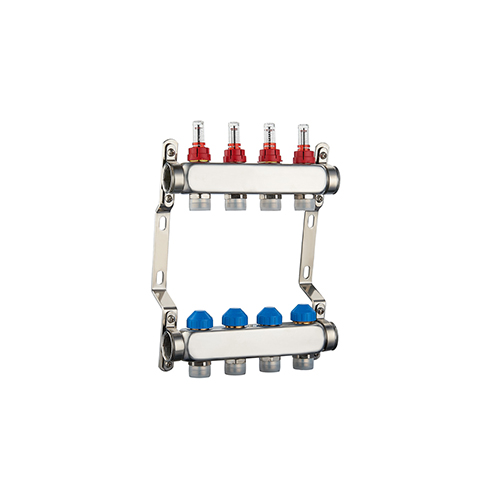

JX-0703

- Stainless steel Manifold

- Stainless steel 304

- Polishing surface treatment

- Operating temperature;-10-110℃

- Working pressure; Max 16 bar

- Connection thread; 3/4″&1/2″ loop

- Hard sealing with a flexible fitting connection.

- Manufactured from corrosion-resistant and durable Stainless Steel to last for life

- Compatible with any PEX tubing – no special adapters needed

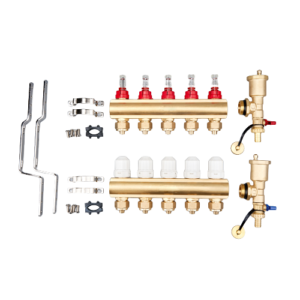

- Mount the Manifold on brackets and connect the valves and PEX tubing

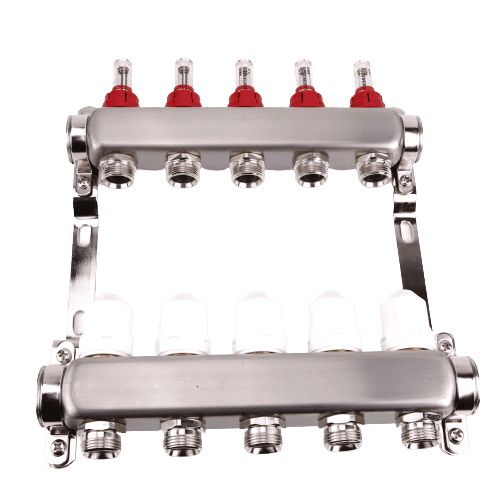

- The Manifold connects the heat source – a boiler, heat pump, or other – with the water underfloor heating circuits, regulates the incoming water temperature via the Mixing Unit and distributes this warm water throughout the floor circuits’ energy-efficient heating system.

- Manifolds are used in all underfloor heating systems above 25m2, irrespective of floor type. Manifolds are supplied complete and fixed with a wall mounting bracket. The Manifold comes complete with a drain and air vent assembly positioned on either end of the Manifold. The isolation valves are supplied separately for the supply end of the Manifold.

- How Heating Manifold Works: Underfloor heating systems comprise pipework installed. This happens within custom underfloor heating insulation panels. The pipework can be applied in various ways forming circuits. A single circuit could be for a single room or area. Many circuits could be far more significant or open areas. Each floor circuit connects to a central Manifold which allows independent control. Manifolds can control more than one circuit concurrently. It can warm different rooms to different temperatures. It can warm by using a zone-specific thermostat also. The Manifold connects the heat source with a boiler. It also connects the heat pump with the water underfloor heating circuits. It adjusts the incoming water temperature via the Mixing Unit. It also allocates warm water throughout the floor circuits. It helps with energy-efficient heating. The underfloor heating circuits are filled and purged with water. It’s because of successful installation & pipework connections. A primary heating circuit makes a connection with a heat source. Sometimes heat sources can provide the essential water temperature without overheating. There is no need to use a mixing unit at that time. The Mixing Unit adjusts the water temperature through an Actuator-controlled Mixing Valve. It also composites the heated water from the primary heating circuit. It happens because of cooler water. It occurs within the floor circuits to achieve the ideal temperature. You can configure this temperature during the installation procedure. It’ll match the designed heat requirements. Heat losses, floor construction, and any other variables determine the requirements.Underfloor circuits maintain the heated water’s flow pressure. Manifolds can support up to 120 Meters of underfloor heating pipes for one circuit. The flow rates for individual circuits are set via the Flow Gauges. It suits the specific circuit’s needs before the water goes through these pipes. The correct configuration ensures that heated zones will heat the space. Corrected setup of flow pressure and flow rates will make an accessible path of transportation. The heated water can be transported from the Manifold into the floor. Manifold’s Flow Arm can occur spontaneously. After circulating the floor circuits, the water re-enters the Heating Manifold. The Return Arm consists of Circuit Valves that are commonly mounted with Actuators. These are being opened and closed as instructed by the Thermostat via the Wiring Centre.

Wiring Centre is a combination of all electrical components. This forges a connection between the Thermostat and the heat source. It is involved with Manifold’s Actuators, Circulators, and any Valves. The actuator works to open the Commissioning Valves. It allows warm water to flow through the circuits. The Wiring Centre also controls the boiler for more heat. It opens any Manifold zone valves. So, finally, it is easy to operate the Mixing Unit Circulator. A Smart Thermostat can control the floor heating. It ensures energy-efficient heating with long-term cost savings. So It can affect your heating bills.

There are a few factors for the location choices of the Heating Manifold. The piping layout is the first consideration of all. The Heating Manifold should always be set up in a location that will reduce the amount of tubing. The manifolds should be accessible because they have valves on them. Closing a manifold in a wall or any support is a worse idea. Reasonable access to a manifold should always be available. Long-time access might not be needed.