FAQs of Tri Clamp Manifold

1. What welding process is used for the tri-clamp manifold?

Plumberstar uses TIG welding. It keeps the welding area completely away from the air.

All our welders are fully certified. They have over 5 years of experience welding high-pressure and sanitary pipes. They know how to read the molten pool. This makes sure every millimeter of the weld meets standards.

When welding, we use argon to protect the welding torch from the outside. We also fill the inside of the pipe with argon. This keeps the inner wall weld bright and free of oxidation. It meets the sanitary standards inside and outside.

After welding, we grind and polish the welds. They blend in with the pipe surface. This gives the smoothness needed for sanitary grades.

Finally, we do pickling and passivation on the whole manifold. This is a chemical process. It removes surface iron ions from welding. It also creates a thicker, denser chromium oxide protective film on the stainless steel surface.

2. What is the pressure test of the tri-clamp manifold?

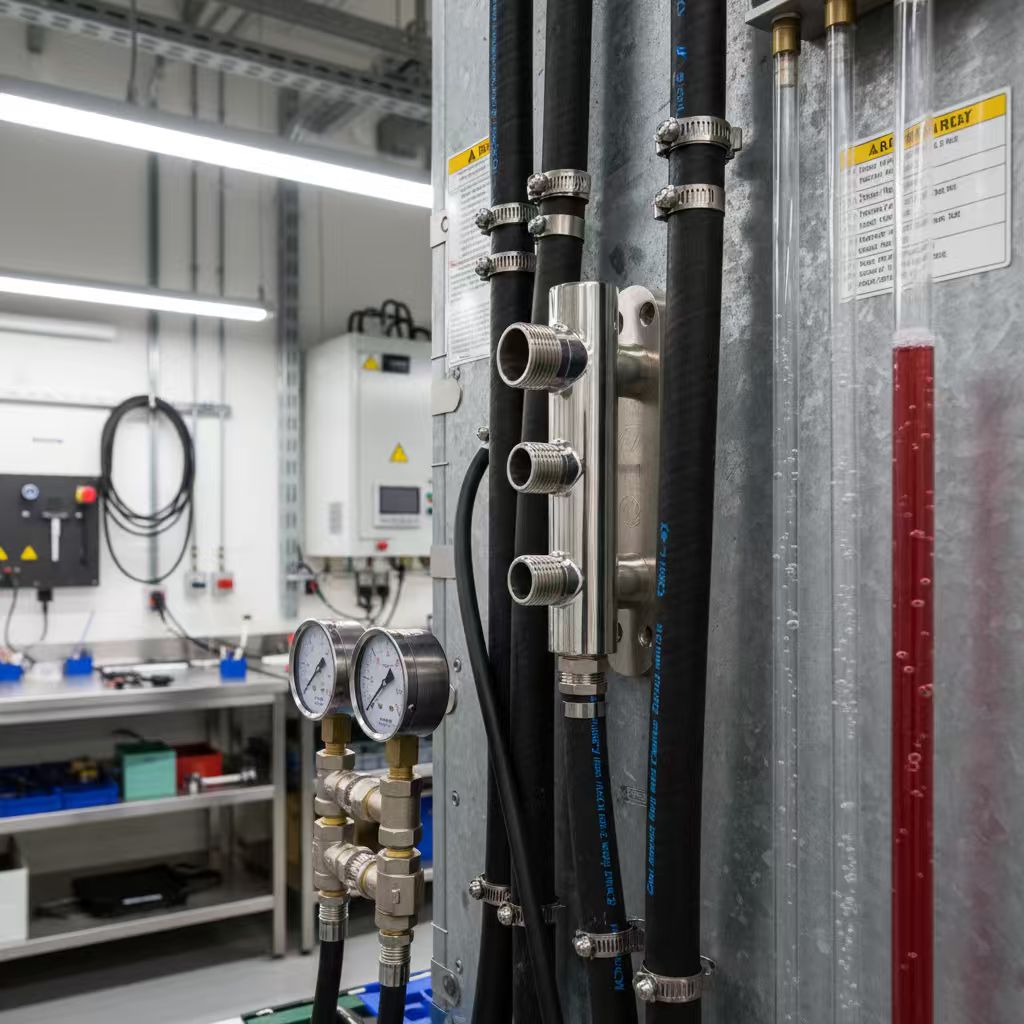

Plumberstar tri-clamp manifolds are pressure tested according to international standards. These include food hygiene, water supply and drainage, and HVAC pipeline standards. All tests are done in our own factory. Every finished product is 100% inspected before shipping.

Before testing, we fully assemble the manifold. We make sure clamp interfaces, plugs, exhaust valves, branch valves, and fittings are installed correctly. Then we fix it on a special pressure test station. We use clean water as the test medium to avoid polluting the inner wall of the pipe.

The test has two parts: the shell strength test and the overall seal leakage test.

For the shell strength test, we use 1.5 times the rated working pressure. We hold the pressure for the required time. We check for deformation, leakage, or cracks on the main body. No obvious pressure drop and no appearance defects mean the test is passed.

For the seal leakage test, we use 1.1 times the rated working pressure. We hold the pressure and check for leaks. We make sure the valve has no internal leakage when closed, and no external leakage at any connection. It meets the zero-leakage requirement for hygienic systems.

We record all test data, including pressure values, holding time, and results. Each record is linked to the production batch for quality traceability.

For customers in food, medicine, chemical, and other high-demand industries, we can test according to your standards or third-party requirements. We also provide official factory pressure test reports.

3. Can the tri-clamp manifold structures be customized?

Of course. As a professional valve customization factory, Plumberstar offers customers one-stop tri-clamp manifold customization. We cover structure, interface size, overall dimensions, and function integration.

All customization work is done in our own factory. This includes design, tooling, production, and pressure testing.

We keep the standard quick-fit clamp connection and reliable sealing. We can adjust the full structure based on your pipeline layout, flow needs, installation space, and system process. This ensures the final product fits your on-site situation.

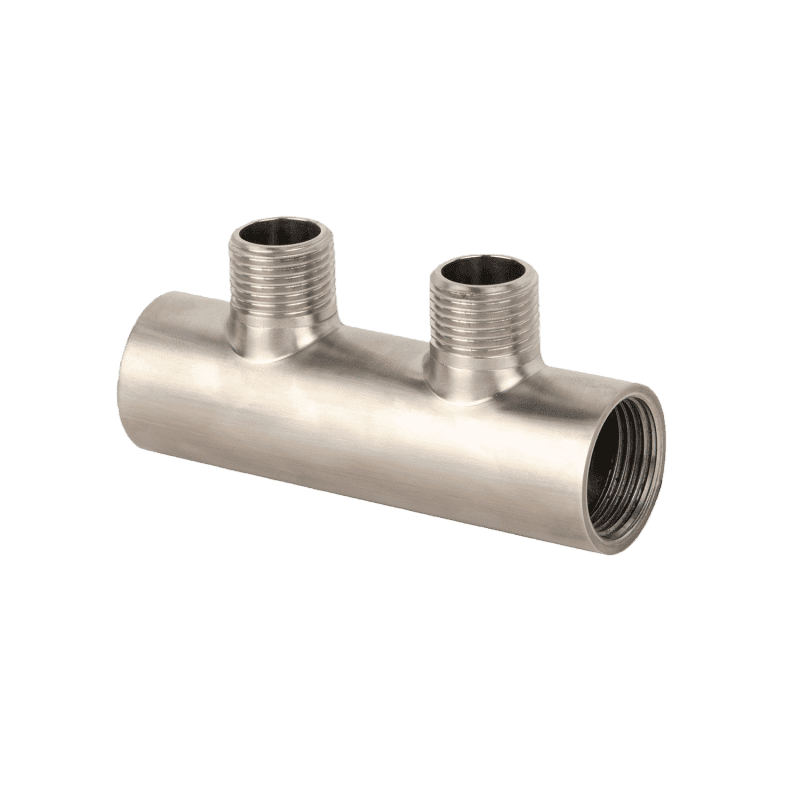

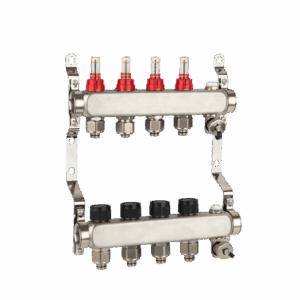

We can change the number of branches and the position of inlets and outlets to match your system. We support 2, 3, 4, 6, or more branches. This meets different pipeline directions and equipment connections.

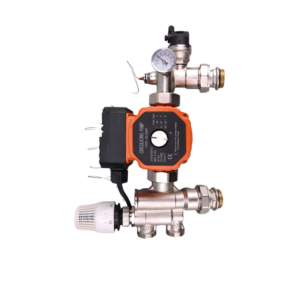

For customers with special function needs, we can add parts like exhaust valves, blowdown valves, pressure gauge ports, temperature sensor ports, and flow control valves. The result is an all-in-one multifunctional quick-fit manifold.

4. Can you provide MTRs for the tri-clamp manifold?

Of course. Plumberstar can provide full Material Test Reports (MTR) for tri-clamp manifolds.

All our tri-clamp manifolds use stainless steel from qualified mills. This includes sanitary grades like 304 and 316L. Each batch of raw materials comes with the original mill test report. It clearly shows material grade, heat number, batch number, chemical composition, mechanical properties, heat treatment, and standards.

We link the heat number, production batch, and order information throughout the process. You can trace every finished manifold back to its raw material details.

We can provide paper MTRs with the goods. We can also send electronic versions early for your pre-audit, customs filing, or third-party checks.

Plumberstar can also provide full-quality documents together. These include spectral test reports, hygiene certification reports, and pressure test reports.

5. How to ensure the center distance of the tri-clamp manifold?

Plumberstar has a full-process control system. It covers design, processing, tooling, and finished product inspection. This keeps the center distance of tri-clamp manifolds precise and stable.

In production, all manifold bodies are machined integrally by CNC. The program sets the hole position, depth, and angle in advance. Positioning accuracy is very high. This keeps the center distance error of each branch within the standard range.

We also use special positioning jigs and center distance fixtures during welding and assembly. The manifold body is fixed firmly in a standard mold. This stops joints from shifting, tilting, or moving during welding or locking. Each joint follows the designed center distance. It avoids size errors caused by manual operation.

After processing, our quality inspectors (with 10 years of experience) check each manifold one by one. They use digital calipers, height gauges, center distance templates, and 3D testing tools.

For mass production, we do first-article confirmation, in-process inspection, and full finished-product inspection. We also keep size traceability records. This ensures the center distance is consistent across the same batch and different batches.

6. What is the difference between brass and stainless steel tri-clamp manifolds?

Plumberstar offers tri-clamp manifolds in two materials: brass and stainless steel. They differ a lot in applicable scenarios, hygiene level, and pressure resistance. We’ll give you the best material solution based on your system, medium, and environment.

For hygiene and industries:Brass manifolds are mostly used for regular heating, floor heating, home cold and hot water systems. They work on common civil and construction projects. But they’re not used in high-hygiene fields like food and medicine.

Stainless steel is the standard for hygienic fluid systems. Its surface is smooth, with no dead corners. It’s easy to clean and doesn’t breed bacteria. It meets hygiene standards for food, medicine, daily chemicals, and pure water. You can use it directly for hygienic pipeline distribution and transportation.

For pressure resistance and strength, Brass uses mature casting or forging processes. It has stable pressure resistance in regular low and medium-pressure heating and water supply systems. It meets most building needs.

Stainless steel manifolds have higher strength, better impact resistance, and water hammer resistance. They’re better for high-pressure fluid transport, circulation systems, and industrial pipelines. They’re rigid, not easy to deform. They work well for industrial scenarios with long-term continuous operation.

Plumberstar brass quick-install manifolds are cost-effective. They’re good for heating and a regular water supply.

Stainless steel quick-install manifolds focus on hygiene. They’re corrosion-resistant and have a long service life. They’re suitable for industrial and high-end systems.

You can choose freely based on your system medium, pressure, industry standards, and budget.

7. Do you maintain QC documentation for traceability for the tri-clamp manifolds?

Plumberstar keeps complete QC quality control files and full-process traceable records for a long time. For every product we ship, we save written and electronic records for each step. This includes raw material incoming, production, pressure testing, and finished product delivery.

Our traceability system starts with raw materials. When key parts arrive — such as stainless steel main pipes, quick-fit joints, valves, and seals — we register all related documents. These include material certificates (MTR), furnace numbers, batch numbers, supplier info, and incoming inspection reports (IQC). We link all of them to the production batch number.

During production, we record data in real time. This includes CNC machining settings, welding records, assembly steps, tool usage, and in-process inspection data (IPQC). Every process can be traced.

For the important pressure tests of quick-fit manifolds — including shell strength and seal leakage tests — we log details for each unit. We record test pressure, holding time, result, inspector, and equipment number. This forms a full pressure test report (FQC). We do a 100% full inspection, full recording, and full traceability.

Every finished product has its own unique production batch number. With this number, you can look up the full chain: raw material batch, production process, test data, assembly staff, and shipping information.

All QC files are saved in both paper and electronic versions long-term. When you need them, we can provide a full set of quality documents at any time. This includes inspection reports, pressure test records, material reports, and certificates of conformity.