Description

|

Brass Flare Branch Tee

Brass Flare Branch Tee is the core connection fitting in fluid transmission systems (especially refrigeration, gas, water supply, and drainage pipeline), widely used in residential gas pipeline branches, air conditioning refrigeration pipeline shunts, commercial kitchen gas connections, and industrial fluid transmission pipelines. Its core purpose is to realize the shunt connection between the main pipeline and the branch pipeline. Meanwhile, the flared interface design can form a tight sealing structure with the pipeline of corresponding specifications. When installed, it is locked with nuts after the flared butt joint. The connection is firm and convenient to disassemble, ensuring the smooth flow of fluid in the pipeline system while meeting the requirements of complex pipeline layouts.

|

|

|

Fossil Fuel Fitting It is specially adapted to the connection accessories of fossil fuel (such as natural gas, liquefied gas, fuel oil, etc.) transmission systems. It is widely used in connection scenes of residential gas pipelines, commercial kitchen gas equipment, industrial fuel oil transmission pipelines, and fossil fuel power equipment such as boilers and generators. The core application is to realize the sealing connection and transition between pipelines, valves and equipment in the process of fossil fuel transportation, so as to ensure smooth fuel transmission without leakage; it can withstand the corrosion of fossil fuel for a long time, and at the same time meet the safety pressure requirements of fuel transportation system, and effectively prevent the safety risks caused by fuel leakage.

|

|

|

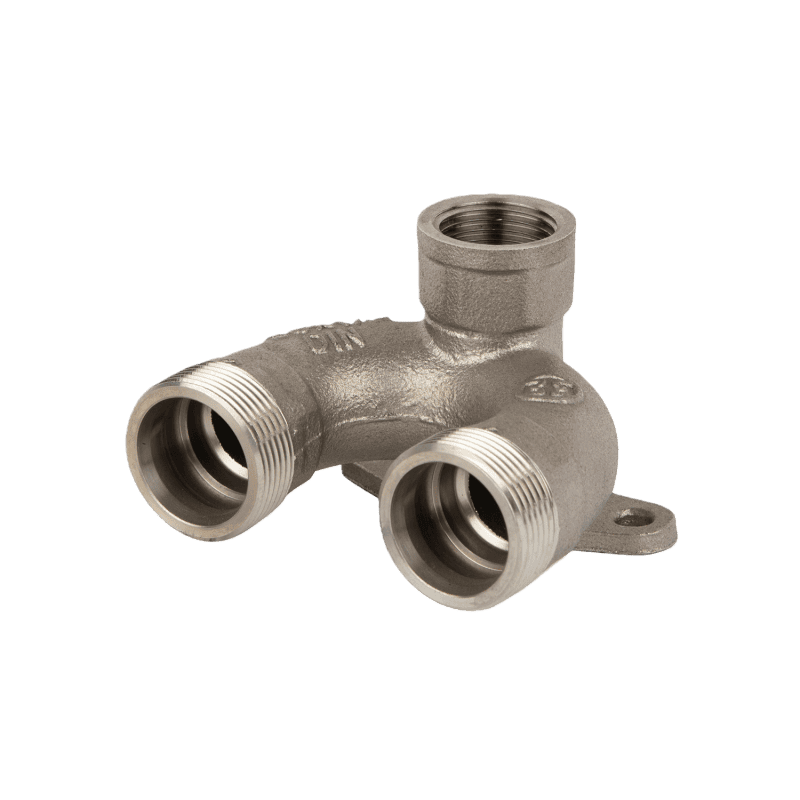

Cast Brass Cleanout Swing Tee

The rotary three-way pipe fittings with a cleaning port, made of cast brass, are the core maintenance and connection parts in water supply, drainage, and industrial fluid pipeline systems. The purpose is to realize the functions of pipeline branch connection, fluid diversion, and pipeline cleaning simultaneously. The three-way structure can facilitate the smooth connection of the main pipeline and branch pipeline through a butt joint, ensuring the circulation of water, neutral liquid, and other media. Rotary design can flexibly adjust the installation direction of branch pipes, adapt to complex pipeline layout, and reserve a seal cleaning port (with removable end cap), which can be quickly opened when the pipeline is blocked, fouled, dredged, cleaned, or inspected.

|

|

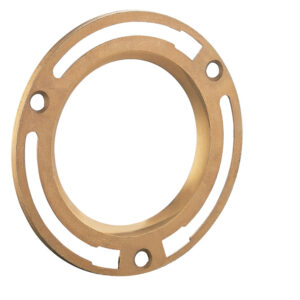

Brass Bulkhead Fitting Brass Bulkhead Fitting is the core connection fitting used to penetrate containers or walls in fluid transmission systems. It is widely used in storage tanks, oil tanks, water tanks, ship bodies, equipment boxes, and building walls. Its purpose is to realize the sealing connection and fixation when pipes pass through container walls or walls. The pipe fittings are firmly installed on the plate wall through flanges and lock nuts, which not only ensure the stable connection between pipes and containers/walls, but also effectively prevent fluid leakage from penetrating the plate. Flexible connection of internal and external pipes.

|

|

|

Bathtub Drain and overflow kit Bathtub drainage and overflow combination accessories are dedicated components of a bathroom system in the bathtub, widely used in household bathrooms, hotel bathrooms, apartment bathrooms, and other types of installation scenes. The purpose is to achieve the dual functions of quick drainage and overflow protection for the bathtub, allowing it to drain the bath water efficiently. The switch design allows for flexible control of drainage speed or temporary storage.

|

|

Brass Tubular Waste End Connection Compl Brass Tubular Waste End Connection Complete is a special drainage fitting for sinks, bathtubs, and other sanitary ware in bathroom systems. Its core use is to connect the drain outlet of sanitary ware to the sewer pipe, thereby constructing a complete and sealed drainage channel. The complete set of components includes a brass drain pipe, joint, seal, and other accessories, which can withstand prolonged exposure to sewage and effectively prevent leakage and odor backflow during drainage. Tubular structure design ensures smoother drainage, making it suitable for a variety of sanitary ware drain and sewer pipe specifications.

|