FAQs of Shower Head Holder

1. Are the valve threads of the Shower Head Holder processed before or after plating?

The threading of the Shower Head Holder is done before electroplating. There are several advantages to this:

- Ensuring thread precision: If electroplating is done first, followed by tapping/thread turning, the plating layer will be cut off. This can result in undersized threads, loose fits, and poor sealing. However, if threads are processed first and then electroplated, the plating layer will cover them evenly, making the thread dimensions more stable. This ensures a more accurate fit during installation and reduces the risk of thread slipping.

- Enhancing corrosion resistance and appearance consistency: Threads also need a plating layer to prevent rust. Processing first and then electroplating allows both the inner and outer walls of the threads to receive a complete plating layer. This avoids rusting caused by local areas without plating.

- Simplifying the process and reducing costs: Integral electroplating after one-time processing and forming is more efficient than the process of “electroplating → reprocessing → local plating repair”. It also prevents damage to the surface plating layer from secondary processing.

If customers are concerned that the threads will become tight after electroplating, the factory will reserve a tolerance for the plating thickness during processing. After electroplating, the threads will just reach the standard fitting size, without affecting installation. In very rare cases, when threads require local insulation/conductivity or high-precision sealing, electroplating is done first, followed by local processing. But this is not applicable to conventional plumbing parts like shower holders.

2. What is the thickness of the chrome plating on your Shower Head Holder?

The multi-layer plating thickness of our Shower Head Holder ranges from 15 to 25 microns. The thickness of the top chrome plating is 0.3–0.5 microns. Compared with other holders of similar price but with a thickness of 0.1–0.2 microns, it offers better cost performance. The bottom layer is also plated with 8–12 microns of copper and 6–10 microns of nickel. The 15–25 micron plating coating has scratch resistance and long-term rust resistance when used in humid environments. It meets the common requirements of the North American and European markets.

We use X-ray fluorescence (XRF) to detect the plating thickness of finished products to ensure the consistency of products in each batch.

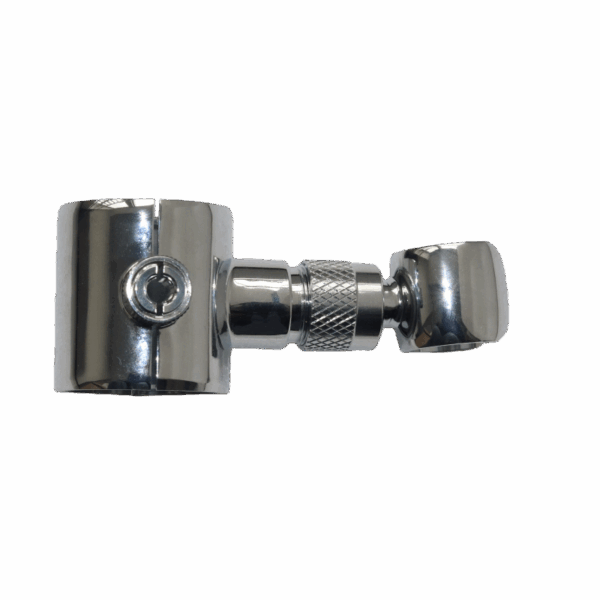

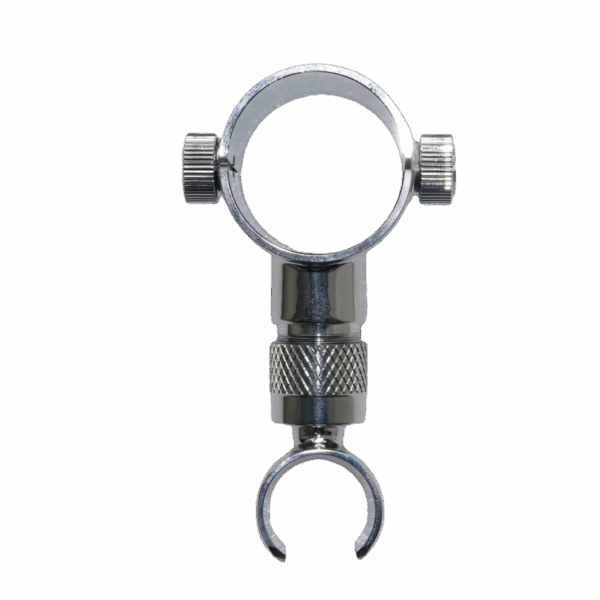

3. Do you offer adjustable shower head holders with swivel ball joints?

Yes, we can customize adjustable shower head brackets with rotating ball joints.

We can customize the rotating ball joints for you using brass or stainless steel materials. They can be designed to have 360° rotation and 45° tilt adjustment functions. The height and water outlet direction of the shower head can be freely set to meet the needs of both adults and children. Additionally, the ball joints can be equipped with reinforced locking knobs. Tightening the knob can securely fix the position. It is suitable for use in humid bathroom environments. And it supports both drill-free adhesive installation and drill-in fixed installation. It is compatible with most standard shower heads on the market and is widely used in home bathrooms, hotels, and rental apartments. The specific design drawings can be provided to you within 4 working days after we have discussed.

4. What is the range of motion for your adjustable holders?

The adjustable range of our adjustable shower bracket is designed to be flexible, which can meet the positioning needs of different shower scenarios:

Rotation angle: The angle of the shower head holder can be adjusted directly by hand. The shower head holder can achieve 360° horizontal rotation, allowing free adjustment of the water outlet direction of the shower head. It also supports up and down 45° flipping, which can flexibly adapt to shower needs at different heights, such as standing and sitting positions.

Height adjustment: The pipe clamp structure on the top can slide freely up and down on the shower rod. It can be fixed at any height after being locked by the knob, flexibly adapting to usage scenarios of different heights.

Adaptability: The pipe clamp of the bracket is compatible with most standard shower rods with a diameter of 22–25mm. Moreover, the holder is designed to be compatible with mainstream sizes of hand-held showers on the market. After installation, there is no shaking, and the positioning is stable.

5. Can we customize the Shower Head Holder packaging with our own brand and instructions?

Yes, Plumberstar fully supports custom packaging for shower head brackets.

1. Brand customization

◦ We can use offset printing, screen printing, or hot stamping to print your company name, product model, and company logo on the packaging box.

◦ You can also specify the color scheme, size, and material of the packaging. We will determine the size and material that can maximize cost-effectiveness. All custom packaging solutions will be ensured to meet international shipping standards to protect the products during transportation.

2. Instruction manual customization

◦ We will design and print user manuals in language versions that meet your requirements to adapt to the target markets (EU/USA/Australia). The manuals can include installation steps, usage precautions, warranty terms, and brand-related content provided by you.

◦ The manuals can be inserted into the packaging or attached to the surface of the product.

6. What is your factory’s defect rate for shower head holders?

The overall defect rate of mass-produced batches stably remains below 0.3%.

- Incoming material inspection: 100% quality inspection is conducted on raw materials. Unqualified materials are rejected at the source.

- In-process inspection: Dimensional accuracy tests and assembly fit tests are carried out during the machining, electroplating, and assembly processes. Deviations are corrected in real-time.

- Finished product inspection: 100% functional tests (rotational flexibility, locking firmness, load-bearing capacity) and appearance checks are performed on finished products before packaging. Unqualified products are directly rejected and reworked.

In addition, there are a very few defective products that may be missed during transportation or use. Our factory can provide replacement or after-sales solutions in accordance with the warranty agreement.

7. Are your quality standards for the Shower Head Holder the same for all export markets?

The core requirement for the quality standards of our shower head brackets is that they remain consistent across all export markets. At the same time, targeted adjustments will be made to meet regional regulations and usage needs.

1. Core Unified Quality Standards

Materials and Processes: All brackets comply with RoHS environmental protection standards. The chrome plating system and thread precision (IT8–IT10 grades) follow unified factory specifications.

Functional Testing: 100% of each batch of products undergoes inspections for 360° rotation flexibility, locking firmness, load-bearing capacity (≥2 kg), and installation adaptability. The overall defect rate is controlled below 0.3%.

Quality Management System: The production process complies with ISO 9001 standards. Complete inspection records can be traced back to each batch.

2. Regional Targeted Adjustments

North American Market: Products must meet the corrosion resistance and load-bearing requirements specified in the ASME A112.18.1 standard. Threaded interfaces adopt the NPT specification.

European Market: Additionally, comply with CE certification requirements. This includes strict testing of heavy metal content in the coating to meet REACH regulations. Threaded interfaces adopt the G/BSP standard.