Description

|

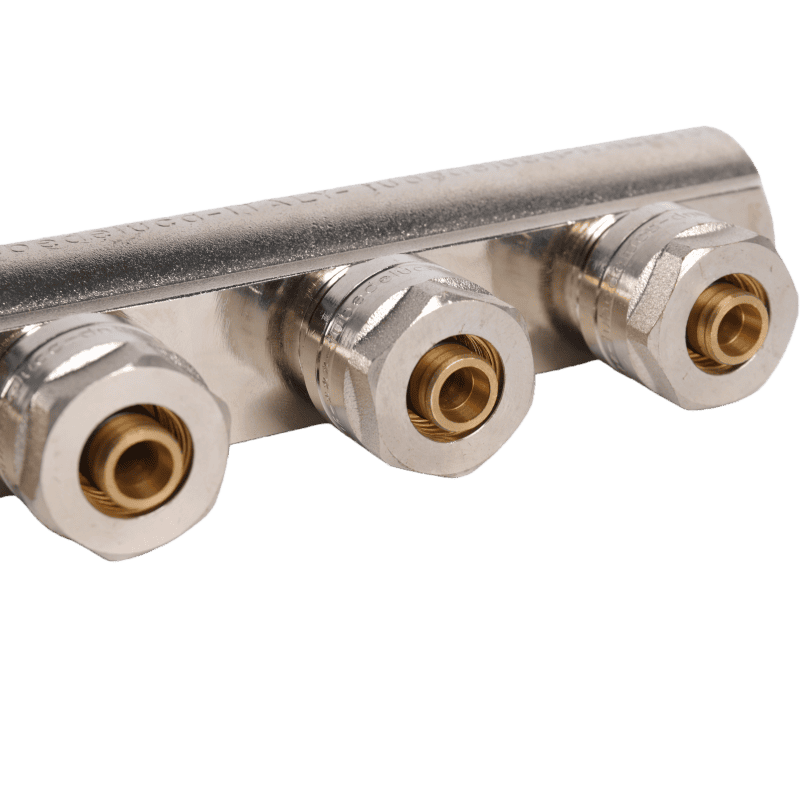

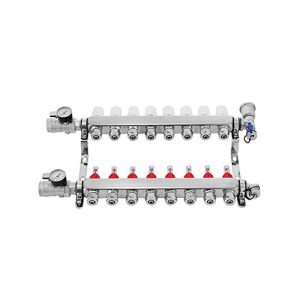

Multi-Outlet Distribution Manifold

As the core component of the end of the circulating water system, the multi-outlet distribution manifold mainly undertakes the task of accurate distribution of water medium, and collects the system water returned from the end, which can flexibly adjust the total flow of circulating water according to the actual operation demand of various heating products.

|

|

|

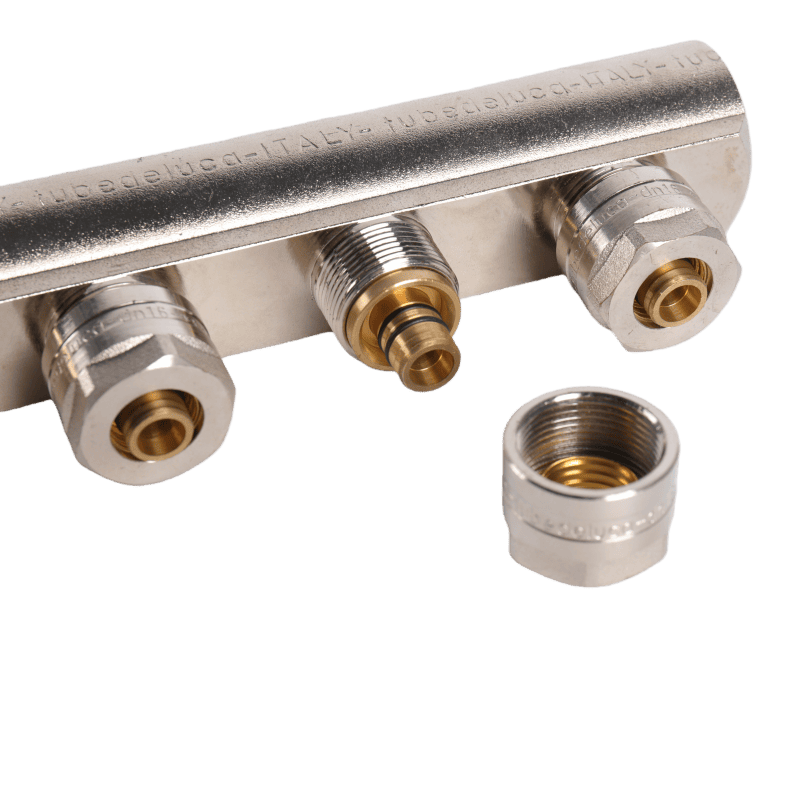

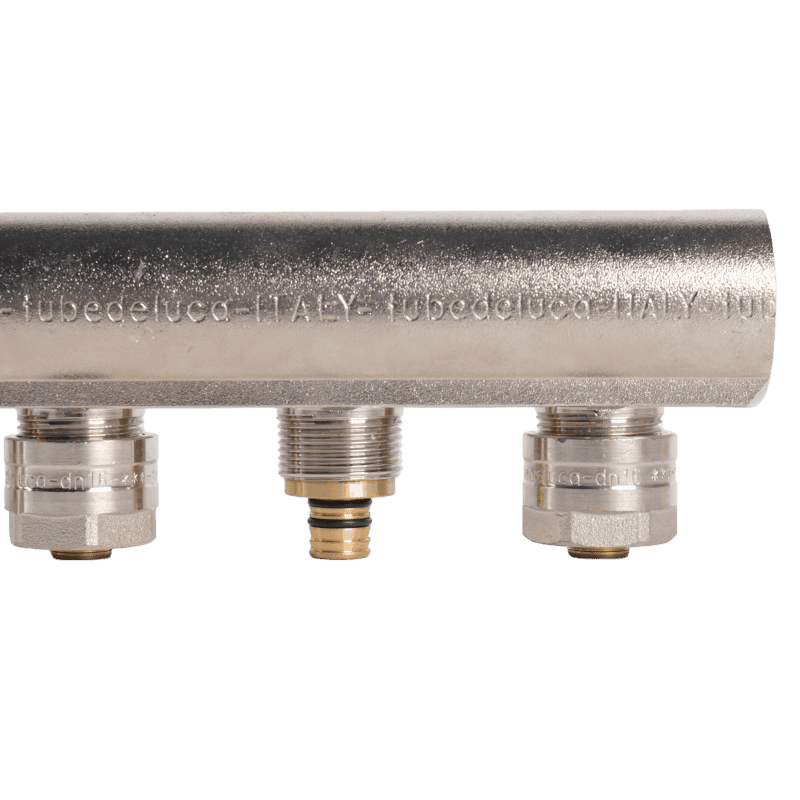

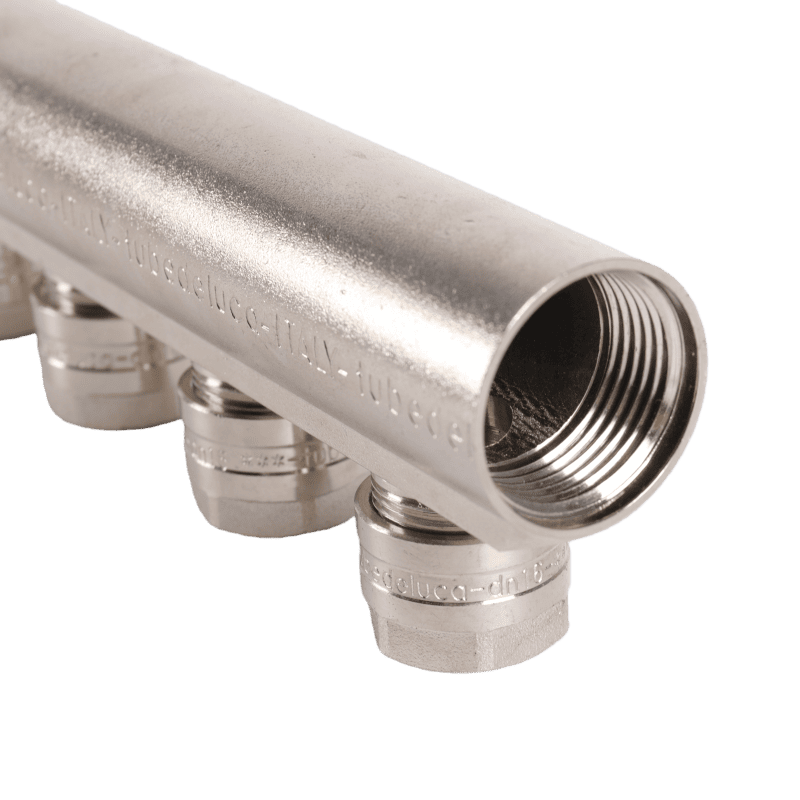

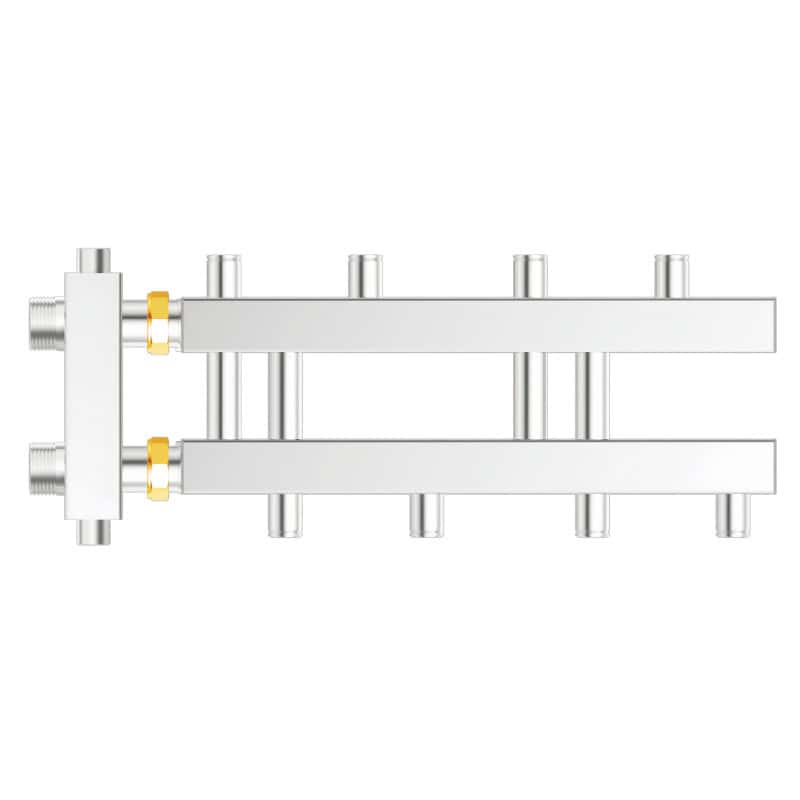

Stainless Steel Hydraulic Balance Water Separator

The function of the stainless steel hydraulic balance water separator is to distribute and converge the fluid in the circulating water system, and at the same time, realize the precise regulation of the water flow of each branch through the built-in structure to ensure the hydraulic balance of different heating/cooling terminals and avoid the problem of uneven cold and heat caused by uneven branch flow and widely used in floor heating, central air conditioning, and other heating engineering pipeline systems.

|

|

|

Mixing Tank Manifold for Heating System

It can cut off the mutual interference between the heat pump and the boiler pump (the influence of both parties can be blocked), can clearly sort out and standardize the operation process of the multi-boiler system, not only greatly improve the overall operation efficiency of the system, but also help the boiler to fully release the maximum power, and provide practical supporting services such as temperature control.

|

|

Manifold Automatic Exhaust Valve

A Manifold Automatic Exhaust Valve is a kind of valve equipment installed in a fluid pipeline. Its function is to automatically exhaust air accumulated in the pipeline, avoid pipeline air blockage, water hammer, thermal efficiency reduction, or equipment corrosion caused by air retention, and it can monitor and exhaust gas in real time during fluid flow without manual operation.

|

|

|

Square Pumping Station Pipe

Square pumping station pipeline is a kind of square-section pipeline component applied in a pumping station system, mainly used for conveying water, heating medium, and other fluids. Compared with a circular pipeline, its square structure is more convenient to arrange and install in a pumping station with limited space, which can improve the utilization rate of site space. At the same time, it can connect the pump body, water tank, valve, and other equipment in the pumping station, which plays the role of stabilizing fluid transmission and adapting system pipeline layout. It is often used for pipeline connections and system expansion of heating and water supply pumping stations.

|

|

Circular Pumping Station Pipeline

The circular pumping station pipeline is a core component of the pumping station system, characterized by its circular cross-section design. It is mainly used for fluid transportation and diversion in heating and water supply systems. Its circular structure features low fluid resistance, high pressure-bearing capacity, and stable compression and impact resistance. This extension tube increases the length of connections between system components, which is especially useful when system configuration changes are required.

|