Description

|

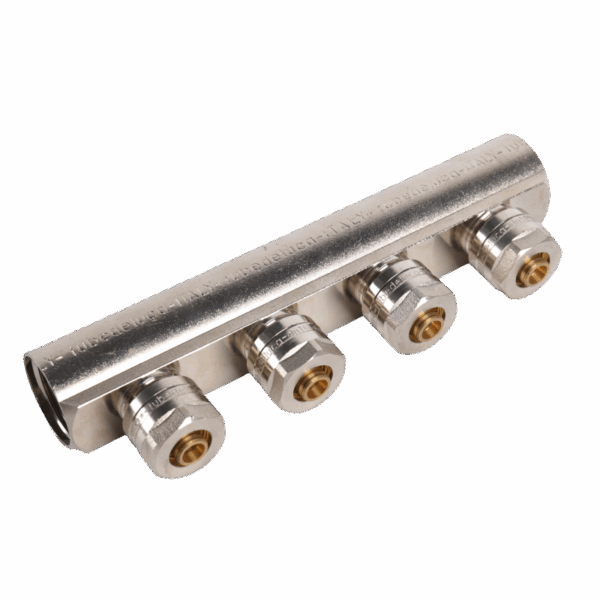

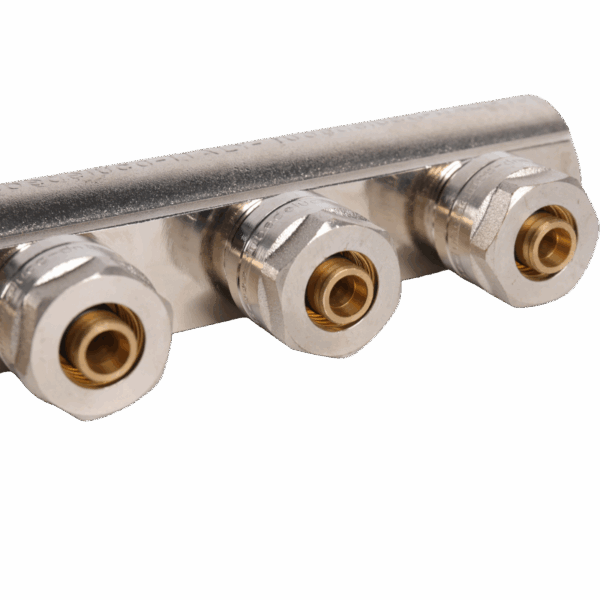

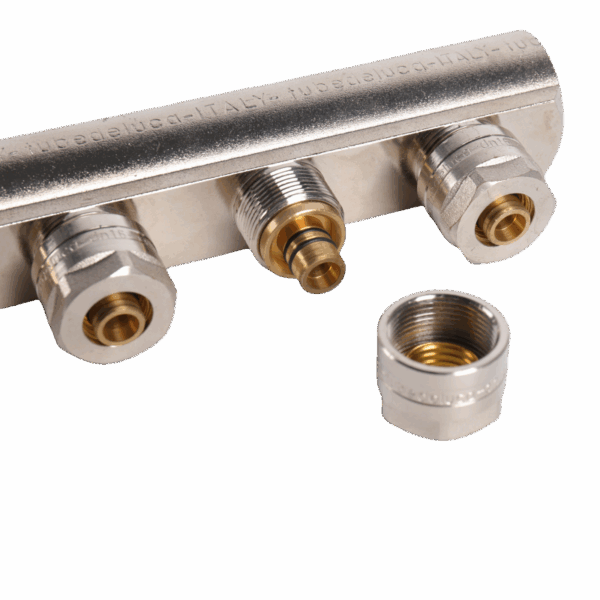

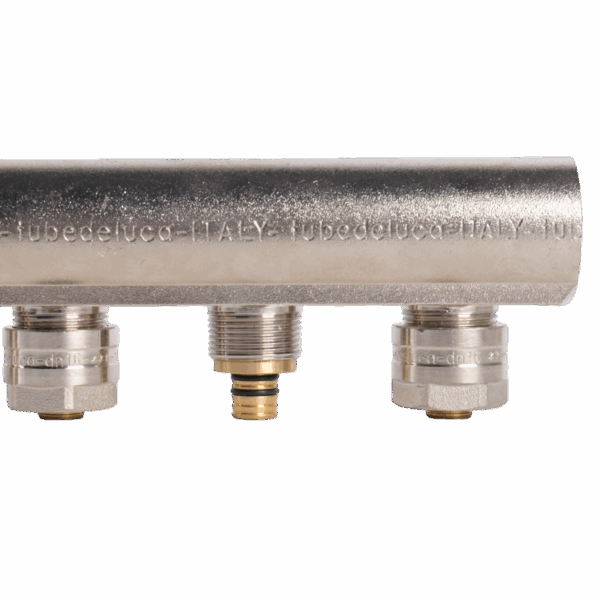

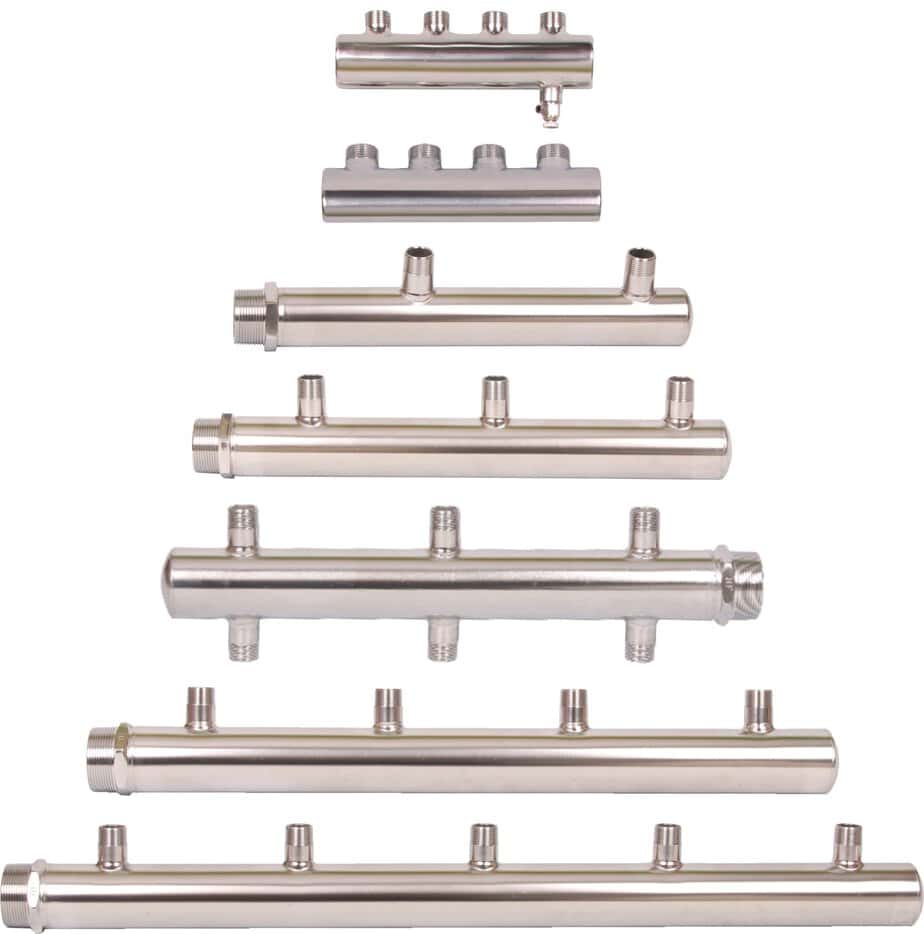

Multi-Outlet Distribution Manifold

The multi-outlet distribution manifold is an important part at the end of a circulating water system. It is used to send water accurately to different pipes and collect water returning from the system. It can also adjust the total water flow flexibly according to the needs of different heating products, helping the system work efficiently and keeping water evenly balanced in all branches.

|

|

|

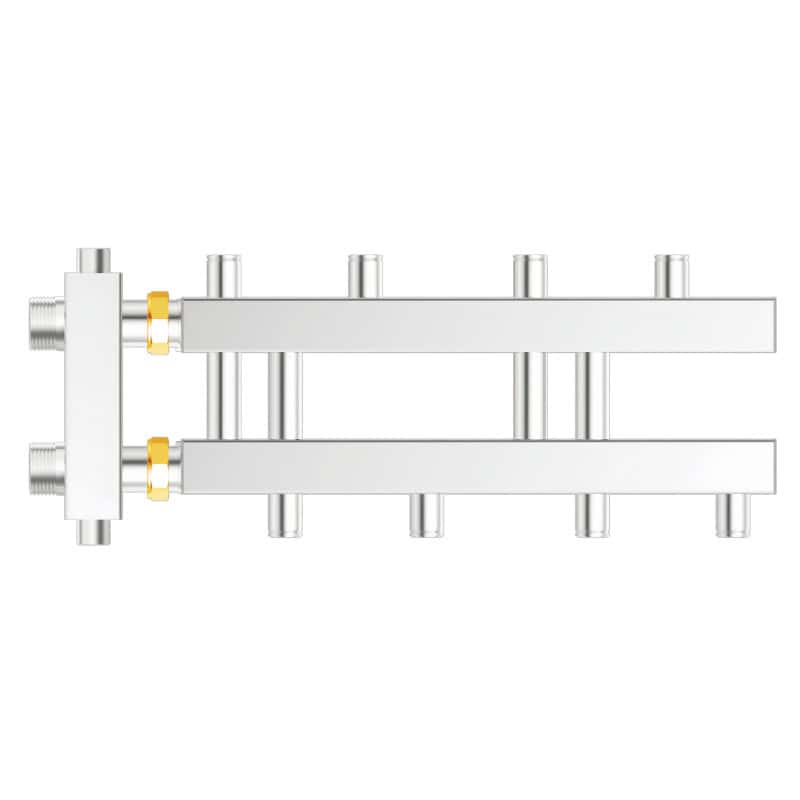

Stainless Steel Hydraulic Balance Water Separator

The stainless steel hydraulic balance water separator is used to distribute and collect water in a circulating system. It can also control the water flow in each branch with its built-in structure. This helps keep all heating or cooling terminals balanced and prevents some areas from being too hot or too cold. It is commonly used in floor heating, central air conditioning, and other heating and cooling pipeline systems.

|

|

|

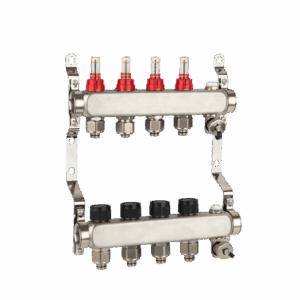

Mixing Tank Manifold for Heating System

It can separate the work of the heat pump and the boiler pump so they do not affect each other. It helps organize and standardize how a multi-boiler system works. This not only improves the system’s overall efficiency but also allows the boiler to work at full power. It can also provide practical supporting services such as temperature control.

|

|

Manifold Automatic Exhaust Valve

A manifold automatic exhaust valve is a valve installed in a pipeline. Its job is to automatically release air that builds up in the pipes. This helps prevent air blockages, water hammer, lower heating or cooling efficiency, and equipment damage caused by trapped air. It can monitor and release air while water or other fluids are flowing, without needing anyone to operate it.

|

|

|

Square Pumping Station Pipe

A square pumping station pipeline is a kind of square-section pipeline component applied in a pumping station system. Compared with round pipes, its square shape makes it easier to arrange and install in pumping stations with limited space. It can connect the pump body, water tank, valve, and other equipment in the pumping station. It is often used for pipeline connections and system expansion in heating and water supply pumping stations.

|

|

Circular Pumping Station Pipeline

The circular pumping station pipeline is an important part of the pumping station system. It has a round shape and is mainly used to carry and guide water or other fluids in heating and water supply systems. Its round design allows fluid to flow smoothly, can handle high pressure, and is strong against compression and impact. This extension pipe increases the distance between system parts, which is especially useful when the system layout needs to be changed or adjusted.

|