Description

|

304 Stainless Steel Gate Valve

Stainless steel gate valves are made of stainless steel. This material boasts excellent corrosion resistance, enabling stable adaptation to harsh operating conditions. Rotating the red handwheel raises or lowers the gate inside the valve body to control fluid on-off, featuring intuitive and convenient operation. Widely used in industrial fields, they regulate the flow of various media such as water, oil, and gas, acting as core flow control components in industrial pipelines.

|

|

|

Brass Angle Stop Valve

The brass angle stop valve is a dedicated plumbing control solution engineered to regulate water flow with Precise control and consistent performance. The valve is equipped with a striking red handwheel, featuring intuitive and easy-to-understand operation that allows for effortless use without professional skills, meeting the needs of various users. Its 90-degree valve body design enables convenient installation, flexibly adapting to narrow spaces and complex pipeline layouts while not compromising water flow efficiency.

|

|

|

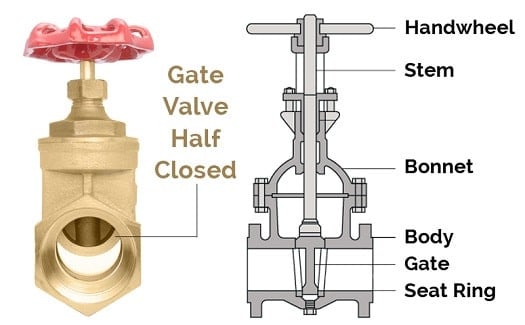

Brass gate Valve With 200WOG

Gate valves are a type of valve that controls the on-off of fluids such as water, gas, and oil through a gate-type valve core. Rotating the red wheel-shaped handle raises or lowers the internal gate to achieve fluid conduction or shutoff. With the advantages of high durability and corrosion resistance, gate valves are widely used in pipeline systems, such as being used as main water shutoff valves. Designed specifically for efficient flow control, the gate lifting mechanism enables fast and reliable conduction or shutoff of fluids such as water, gas, and steam.

|

|

Brass Safety Relief Valve

Brass safety relief valves (also known as pressure relief valves or “pop-up” valves) are core safety components installed in pneumatic or hydraulic systems, specifically designed to prevent system damage caused by overpressure. Their working principle is simple and efficient: when the pressure acting on the valve seat exceeds the preset threshold and is sufficient to overcome the internal spring tension, the valve automatically opens to quickly release excess pressure and balance the system pressure. With a wide range of applications, this valve can be matched with various systems such as hot water boilers, water heaters, pressure tanks, and pipelines.

|

|

|

Brass Angle Ball Valve

Brass angle globe valves are commonly used shut-off valves in pipeline systems, mainly designed for flow control of various liquids and gases such as water, natural gas, and crude oil. They serve as basic flow control components in industrial pipelines and are also widely installed in residential water and gas supply lines, accurately regulating the on-off of media for various indoor water and gas-consuming equipment. With their robust and durable characteristics and reliable sealing performance, they can stably adapt to high-pressure working environments and ensure flow control safety under system pressure; meanwhile, thanks to the advantages of easy operation and low maintenance costs, they are widely applied in multiple industries including chemical processes, petroleum, water treatment plants, heating, ventilation, and air conditioning (HVAC), pipeline engineering, and food and beverage.

|

|

Parameters of Pex Fitting Straight Coupling Push Fit

Push-to-connect pipe fittings are connectors that enable quick pipe connection without welding, clamps, or glue. They feature strong versatility, compatible with pipes of various materials such as copper pipes,PEX pipes, CPVC pipes, and PE-RT pipes. Suitable for potable water systems and hot water heating systems, they meet the basic pipeline needs of residential and commercial scenarios. Meanwhile, they support underground burial or concealed installation in walls, requiring no reserved access holes, perfectly adapting to the needs of concealed pipeline arrangements.

|