Description

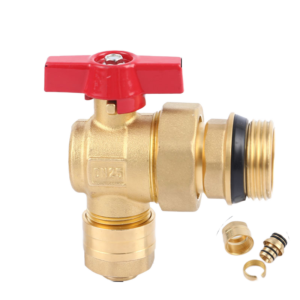

High-Pressure Stainless Steel Ball Valve For Natural Gas

JX-0412

- Connection Type: Female NPTXNPT and BSP x Female BSP

- Port Type: Threaded (ferrule, BW butt welding, SW socket welding, UBM union butt welding, etc.)

Operating Temperature: -60℃160℃

Pressure Environment: 6000PSI, up to 10000PSI max.

Drive Mode: Handle (electric, pneumatic)

Nominal Diameter: DN25 (ranges from DN6DN50)

Material: 304, 316SS, 321, Hastelloy, Monel alloyBH series high-pressure ball valve has a light torque, and the valve seat features high-pressure displacement compensation, making it suitable for harsh conditions like hydrogen energy and gas.Handle color is customizable.

Full operating pressure for any port.

Seat wear compensation function.

Various end connection types available.

Features a self-sealing anti-blowout stem with an anti-loose stem design.

Pneumatic and electric actuators are optional.

Strict gas performance testing is conducted on each valve at the factory’s maximum working pressure.

Introduction: The Growing Demand for High-Quality Valves

In today’s energy-driven world, safety, efficiency, and durability are paramount, especially in the natural gas industry. One unsung hero facilitating these attributes is the humble valve, particularly the high-pressure stainless steel ball valve.

What is a Stainless Steel Ball Valve?

A stainless steel ball valve controls flow using a hollow, perforated, pivoting ball. This valve is open when the ball’s hole is aligned with the flow and closed when rotated 90 degrees by the valve handle. Stainless steel, known for its durability and resistance to corrosion, ensures that these valves can withstand challenging environments.

Benefits of Using Stainless Steel in High-Pressure Scenarios

- Corrosion Resistance: Stainless steel, especially in high-pressure environments, resists corrosion that can compromise valve integrity.

- Durability: Able to endure high pressures without wear and tear, ensuring longer operational life.

- Temperature Tolerance: Stainless steel remains stable even at high temperatures, a common scenario in gas applications.

- Cost-Efficiency: Longer-lasting materials reduce the frequency of replacements and maintenance.

Why Natural Gas Applications Demand the Best Valves

Natural gas, while a cleaner fuel, poses risks. Any leaks or failures can result in catastrophic events. Hence, the infrastructure supporting natural gas must be of the highest quality, ensuring safety, efficiency, and the trust of consumers and businesses.

Key Features of High-Pressure Stainless Steel Ball Valves

- Full Port Design: Maximizes flow and reduces system pressure loss.

- Tight Seals: Ensures no leaks, which is critical when dealing natural gas.

- Locking Handles: Prevents unintentional opening or closing, ensuring safety.

- Blow-out Proof Stem: Further ensures safety by preventing stem expulsion due to internal pressure.

Considerations When Selecting Your Valve

- Pressure Ratings: Always ensure the valve’s pressure rating matches or exceeds your system’s requirements.

- Connection Types: Whether threaded, flanged, or welded, ensure the valve connects seamlessly with your system.

- Size: Choose the right size for your application, ensuring effective flow control.

- Certifications: Ensure the valve has been tested and certified for gas applications, emphasizing safety and compliance.

Investing in Safety and Efficiency

Cutting corners isn’t an option in the demanding world of natural gas applications. The high-pressure stainless steel ball valve is reliable, efficient, and safe for those looking to ensure their systems run optimally. Investing in quality now means fewer risks, reduced maintenance, and a long-lasting procedure that won’t disappoint you.

With the proper considerations and an understanding of why these valves are vital, businesses and contractors can make informed decisions, ensuring that future energy systems are secure, efficient, and reliable.

Stainless Steel Composition:

Stainless Steel 201:

- Contains a lower percentage of nickel compared to 304.

- Manganese is added to help counteract any loss of corrosion resistance due to the lower nickel content.

- Contains around 0.15% carbon, 16%-18% chromium, 3.5%-5.5% nickel, and 5.5%-7.5% manganese.

Stainless Steel 304:

- Known as A2 stainless in some sectors.

- It contains 18% chromium and 8% nickel, making it ultra-resistant to corrosion.

- Contains around 0.08% carbon, 18%-20% chromium, and 8%-10.5% nickel.

Stainless Steel 316:

- Known as marine-grade stainless steel.

- It cIt contains an addition of molybdenum that improves corrosion resistance, especially to chlorides and other industrial solvents.

- Contains around 0.08% carbon, 16%-18% chromium, 10%-14% nickel, and 2%-3% molybdenum.

Corrosion Resistance:

Stainless Steel 201:

- Good resistance to corrosion at room temperature, but less corrosion resistant than 304 or 316.

- Not recommended for use in environments with corrosive chemicals or high chloride exposure.

Stainless Steel 304:

- Excellent corrosion resistance for most applications.

- It can resist most oxidizing acids but may suffer corrosion in chloride-rich environments, making it unsuitable for saltwater applications.

Stainless Steel 316:

- Superior corrosion resistance compared to 201 and 304 stainless steels.

- Exceptionally resistant to chloride pitting and is often used in marine environments.

- The added molybdenum gives it higher resistance to certain types of deterioration and corrosion.

Intended Application:

Stainless Steel 201:

- Often used for indoor applications and kitchen appliances.

- Commonly used for cookware, hose clamps, and architectural decorations.

Stainless Steel 304:

- The most common form of stainless steel is used in various industries.

- They are used for home appliances, surgical instruments, food processing equipment, and even aerospace structures.

Stainless Steel 316:

- Used where high resistance to chloride corrosion is required.

- Common in marine equipment, pharmaceuticals, surgical instruments, and other high-chloride environments.

In conclusion, while 201, 304, and 316 stainless steels may seem similar initially, their different alloying elements make them suitable for various applications. Always choose the grade that best suits the specific environment and use-case scenario.