Description

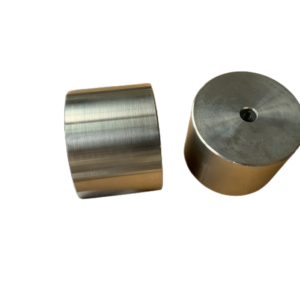

Ground Clamp

Non-Direct Burial Pipe Clamp – ½ Inch – 1 inch Pipe Range

JX-0859

High-Conductivity Ground Pipe Clamp

1- 1/4Inch – 2 inch

2 -10 Wire Range, 1/4 – 20 Screw Thread

Direct Burial Rebar Pipe Clamps for grounding to Water Pipe and Rebar

They are made from solid cast bronze and lead-free of high strength and high conductivity. Copper alloy

For Connecting Grounding Conductors to Water Pipe, Copper Tubing, Ground RodUL Direct Burial Ground Pipe, and the Clamps have screws made of solid brass

Ground clamps may not often be in the limelight, but their importance in electrical systems is paramount. This guide will take you through the basics, significance, and proper utilization of ground clamps.

Definition and Purpose:

A ground clamp is a connecting device to ensure a stable electrical connection between an object and the ground of an electrical circuit. Its primary purpose is to prevent unwanted voltage on equipment and to protect against electrical shock, ensuring safety and equipment integrity.

Materials and Construction:

Ground clamps are generally made from conductive materials like brass, bronze, or copper, which offer excellent electrical conductivity and resistance to corrosion. Some are plated with other materials to increase durability.

Different types of ground clamps

Many ground clamps are available on the market, each designed for a specific purpose. The most common type of ground clamp is the pipe clamp, used to secure pipes to a structure. Other ground clamps include the cable clamp, used to connect cables to a structure, and the wire clamp, used to secure a system. Ground clamps are used in many industries, including the construction and electrical industries. They are used to help secure equipment to a structure. Ground clamps can connect wires, pipes, and cables to structures.

Types:

- Rod Ground Clamps: Typically used for attaching grounding conductors to ground rods.

- Pipe Ground Clamps: Designed to connect grounding wires to pipes, fences, or other cylindrical objects.

- Lay-In Ground Clamps: Convenient for situations where the clamp must be installed after the grounding wire is in place.

Key Features:

- Durability: Most ground clamps are built to withstand harsh environments, especially those meant for outdoor use.

- Versatility: They can be used in various settings, including residential, commercial, and industrial applications.

- Simplicity: Ground clamps are designed for easy installation, requiring minimal tools and expertise.

Applications:

Ground clamps are crucial in electrical installations, grounding, lightning protection, and utility power distribution networks. They ensure that electrical devices and structures are adequately grounded, reducing the risk of electrical malfunctions or dangers.

Safety First:

Proper grounding is a crucial aspect of electrical safety. It allows unwanted electrical current to dissipate safely into the earth, minimizing the risk of electric shock or fire.

Maintenance and Inspection:

Regularly inspect ground clamps for signs of corrosion, damage, or wear. Ensure that connections remain tight, and replace any damaged clamps immediately. Ground clamps are vital in electrical safety, ensuring systems and equipment are properly grounded. While they may seem like simple devices, choosing the suitable ground clamp for your application and providing its proper maintenance can significantly enhance the safety and effectiveness of your electrical systems.

What is a ground clamp?

A ground clamp is a device used to ensure a good electrical connection between a metal object and the earth. This is important to prevent electrocution or damage to equipment. Ground clamps are used in many industries, including construction, mining, and manufacturing. There are several different types of ground clamps, each designed for specific applications. The most common type of ground clamp is the copper-bonded type, which is designed for use with copper pipe or tubing.

The importance of using a ground clamp

A ground clamp is an important safety device that should be used when working with electrical wiring. The clamp helps to ensure that the electrical current goes where it is supposed to go, not into your body. Using a ground clamp will also help to maintain your equipment. The clamp should be connected to the metal frame of the work area or whatever else is made of metal and is at ground level.

You must use a ground clamp if working with any electrical wiring. This will help to prevent any electricity from accidentally entering your body. While most people consider electric shocks relatively harmless, they can cause serious harm or even death.

Using a ground clamp is easy and only takes a few seconds, so there is no excuse not to use one. Plenty of resources are available online or at your local hardware store if you are unsure how to use a ground clamp.

A ground clamp is a device that connects a conductor to the earth or another large conducting body to create a safe electrical environment. The use of ground clamps helps protect people and equipment from electrical hazards. Ground clamps are an essential part of any electrical safety program. The most common purpose of a ground clamp is to protect personnel from electrical shock. This is especially important in industrial settings. For example, generators, motor control centers, and other electrical fixtures are often located outside or indoors in the middle of large spaces.

Brass Ground Clamp Vs. Bronze Ground Clamp:

The need for effective grounding in electrical systems cannot be overstated. It is a crucial requirement that ensures the safety and functionality of electrical installations. Central to achieving this is the use of ground clamps, which create a reliable connection between the grounding conductor and the ground rod. But when it comes to choosing the right material for these clamps, a debate often arises: Brass or Bronze?

The dilemma stems from the similar appearance and substantial properties both materials offer. However, delving a bit deeper into their characteristics reveals subtle differences that could be game-changers in certain scenarios.

With safety as a priority and efficiency a necessity, the choice between brass and bronze ground clamps becomes more than just a matter of preference.

What Defines Brass and Bronze Ground Clamps?

Brass and bronze, though often mistaken for each other, have distinct compositions. This difference in composition results in distinct properties, which in turn impact the performance of ground clamps made from them.

Brass Ground Clamps:

- Brass is an alloy of copper and zinc.

- It is known for its good conductivity, corrosion resistance, and machinability.

- Brass clamps are typically more malleable, making them easier to shape as needed.

Bronze Ground Clamps:

- Bronze is primarily an alloy of copper and tin.

- It is renowned for its superior corrosion resistance, especially against seawater corrosion.

- Bronze clamps are stronger and more durable, though less conductive compared to brass.

How Do They Fare In Performance?

Conductivity: Brass, having a higher copper content, generally offers better electrical conductivity, which is vital for effective grounding.

Corrosion Resistance: On the other hand, bronze stands out when it comes to resisting corrosion, making it a preferable choice in harsh environments, particularly those with salty or acidic conditions.

Durability and Strength: Bronze clamps win in the durability and strength department, ensuring a long-lasting grounding connection even under stressful conditions.

Cost and Availability: Brass clamps tend to be more readily available and might come with a lower price tag as compared to bronze clamps, which could be a determining factor for budget-conscious projects.

Which One Should You Choose?

The decision between brass and bronze ground clamps boils down to the specific requirements of your project.

- If electrical conductivity and cost are your primary concerns, brass ground clamps would serve you well.

- Conversely, bronze would be the go-to material if you are dealing with harsh environmental conditions and require a robust and durable grounding clamp.

Conclusion

Both brass and bronze ground clamps have their unique sets of advantages. Your project’s unique conditions and requirements would significantly influence your choice between the two. By assessing the environment, budget, and the level of conductivity required, you can make an informed decision that ensures both safety and efficiency in your electrical installations.