Description

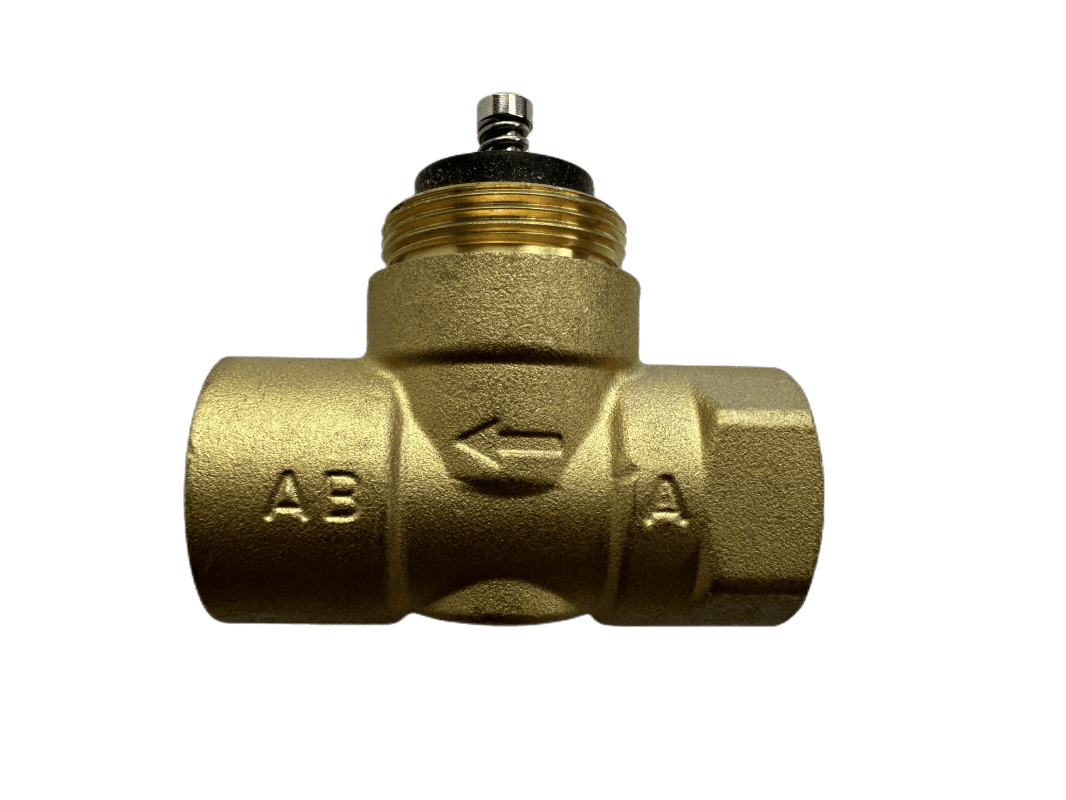

Electric Two-Way Globe Valve Body

JX-0909

BSP Threaded Straight Pipe End Connection, Stem Up Open, Brass Plug, 3/4″ Port Size

2 way and 3 way, both are welcome.

230v and 24v, DC and AC are both available.

Designed to work with either a pneumatic or electronic actuator with a 3/4-inch (20 mm) stroke, Two-way Globe Valves are available in ANSI Class 250 for Normally Closed or Normally Open action.

• Direct-coupled bonnet

• Equal percentage or linear flow characteristics

• Brass or stainless steel trim

• Factory orderable as: – Valve only – Valve and Actuator

• Accepts any 3/4-inch stroke Flowrite pneumatic or electronic actuator

• ANSI Leakage Class IV (0.01% of Cv)

• Cartridge-type packing for easy service

• Multiple end connections available

The Two-Way Brass Body of the Actuator Ball Valve is an actuator valve used in various applications. It is designed with two ports – one for the upstream fluid and one for the downstream port- to provide different pressure drop levels when actuated.

The valve is designed to provide a low-pressure drop throughout the closed, flow-restricted position and a high-pressure decline in the fully open position.

Black & Veatch has provided hundreds of these actuator valves for clients across North America. The design can be made as a one or two-port model with either a metal flange-style mounting base (to suit most piping designs) or end connections for more specific applications such as instrumentation systems, gas plants, and many others that require reliable actuation technology procedures.

What is a Brass Electric Ball Valve?

A brass electric ball valve is a type of valve that controls the flow of liquid or gas in a piping system. This type of valve works by using an electric current to open and close, allowing precise and reliable control over the flow rate. A brass electric ball valve consists of a body, handle, stem and seat, creating a tight seal when in the closed position. The body material is typically made from brass which gives it excellent corrosion resistance and durability. The handle can be manually operated or as part of an automated system with an electric motor connected to it for remote operation.

The advantages of brass electric ball valves are their low-pressure drop, fast-acting shutoff capability, and long-term reliability for various industrial applications.

Types of Brass Electric Ball Valves

Brass Electric Ball Valves are essential components of modern plumbing systems. They are versatile and reliable, providing a secure way to control the flow of liquids or gases. Several types of brass electric ball valves are available for use in different applications, each with distinct advantages and disadvantages.

The most basic type is the full port valve, which provides unrestricted flow through a pipeline when open. This type is often used in systems that require high-flow rates, such as firefighting or commercial water distribution. Another common type is the reduced port valve, which has an internal diameter slightly smaller than the full port valve; this reduces turbulence and helps conserve energy during normal operation.

Installation and Maintenance

Installing and maintaining a brass electric ball valve body is essential for the long-term functioning of any plumbing system. This type of valve is designed to regulate the flow of liquids and gases, making it an ideal choice for controlling water or other fluids within a network. However, this type of valve can be prone to leaks or failure without proper installation and maintenance.

When installing a brass electric ball valve body, it is important to ensure that the threading is correctly aligned with the associated pipes and fittings within the plumbing system. It is also crucial to ensure that all connections are securely tightened so as not to cause any leakage during operation. Additionally, for the ball valve body to run smoothly, it should be lubricated periodically according to manufacturer instructions.

Tips for Selecting the Right Valve Body

Several factors must be considered when selecting the correct valve body for a brass electric ball valve. First and foremost, it’s essential to determine which type of material is best suited for the application. Brass is one of the most commonly used materials due to its strength and resistance to corrosion. It can also be machined easily, making it ideal for intricate designs and shapes. Also, brass has excellent temperature tolerance, making it suitable for various applications.

In addition to material selection, size is another key factor when selecting a valve body. Different sizes are available depending on the flow rate that needs to be regulated or monitored. The size of the valve body must match up with other components to ensure proper functioning and performance.

Advantages of Choosing a Brass Electric Ball Valve

Brass electric ball valves are popular for many industrial and commercial applications due to their durability, reliability, and cost-effectiveness. These valves offer excellent corrosion resistance and can be used in various mediums such as oil, gas, water, air, and steam. They also provide precise control over the flow of liquids or gases and are easy to install and maintain.

A brass electric ball valve is an ideal choice for many industries because it provides superior performance at an affordable price. This valve type offers maximum leak prevention when properly installed with no additional accessories required. The material is highly durable, so you won’t have to worry about replacing it anytime soon. It’s also very resistant to corrosive agents, making it suitable for use in harsh environments like marine settings or chemical plants.