FAQs of Shower Swivel Elbow

1. What scenarios are Plumberstar’s shower swivel elbows mainly used in?

Plumberstar’s shower rotary elbow core is suitable for all types of bathroom scenes. It is not only suitable for the installation and transformation of shower pipes in family bathrooms, but also for the batch assembly of commercial bathroom spaces, such as hotels, apartments, and bed and breakfasts (B&Bs). At the same time, it can be used for the later maintenance and optimization of the shower system, such as addressing issues with shower position offset and hose winding. It can also be used with various types of shower equipment, such as constant-temperature showers and pressurized showers. It is widely used in new residential decoration, bathroom upgrades in old rooms, and engineering bathroom support scenes.

2. What are the core competitive advantages of Plumberstar’s Shower Swivel Elbow?

Shower Swivel Elbow’s core competitive advantage is reflected in its integration of multidimensional performance and practical value.

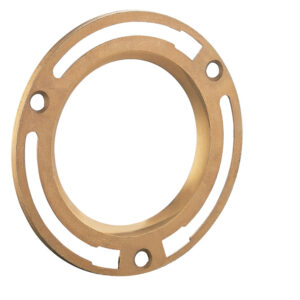

The material features a high-quality brass substrate that conforms to NSF 61 and other lead-free environmental protection standards. The surface can pass the salt spray test of the IEC 60068-2-52 standard after chrome plating and other processes. It exhibits excellent corrosion resistance and aging resistance, with a service life that can span decades.

Functionally, it supports 360° universal rotation and smooth adjustment without jamming. It can flexibly adapt to the shower angle requirements of different height groups. At the same time, it can reduce water outlet resistance by optimizing the internal structure and achieve long-term leakage prevention with EPDM seals, thereby avoiding hose winding problems.

In terms of installation and adaptation, it utilizes universal G1/2, NPT1/2, and other interface specifications, ensuring compatibility with various brand shower systems. It can be assembled without professional tools, and supports non-standard size customization to meet the needs of special scenarios.

The quality meets CE, WRAS, and other international certification standards. Each batch is strictly sealed and tested for size accuracy. In addition, it has the characteristics of high-pressure resistance (usually up to 10-16Bar) and high-temperature resistance (≤120℃). It can adapt to complex usage environments, such as high water pressure and coastal high-salt fog, taking into account the diverse needs of commercial settings, including homes, hotels, and apartments.

3. What is the thickness of the Shower Swivel Elbow coating? Can you pass the salt spray test?

Shower Swivel Elbow’s surface coating thickness follows the high standards of the bathroom industry, using a three-layer plating process of “copper priming-nickel transition-chromium cover”, in which the copper coating thickness is not less than 15μm, the nickel coating is not less than 7.5μm. The chromium coating is not less than 0.25 μm, which not only ensures adhesion of the coating but also improves its wear and scratch resistance.

The product can easily pass the salt spray test, according to ISO 9227-2022 neutral salt spray test standard, in 5% sodium chloride solution, 35±2℃ environment continuous test for more than 480 hours, the surface without rust, bubbling or coating peeling phenomenon, some high-end models exported to Europe and the United States market adopt enhanced coating technology, can pass the salt spray test for more than 1000 hours, fully meet the coastal high salt spray areas and humid bathroom environment requirements.

4. What equipment and processes are used in the Shower Swivel Elbow manufacturing process?

The Shower Swivel Elbow utilizes advanced, delicate equipment and technology throughout its entire production process. The blank stage achieves automatic cutting and upsetting integrated processing through a multi-station cold heading machine, ensuring the initial forming accuracy of the brass substrate and achieving a metal utilization rate of over 90%.

The main body molding process utilizes CNC hot pushing machines or internal and external die cold extrusion equipment, depending on the material. It cooperates with the DW25CNC automatic pipe bending machine to achieve accurate 90° bending, ensuring a curvature radius tolerance of ±0.1mm through program control.

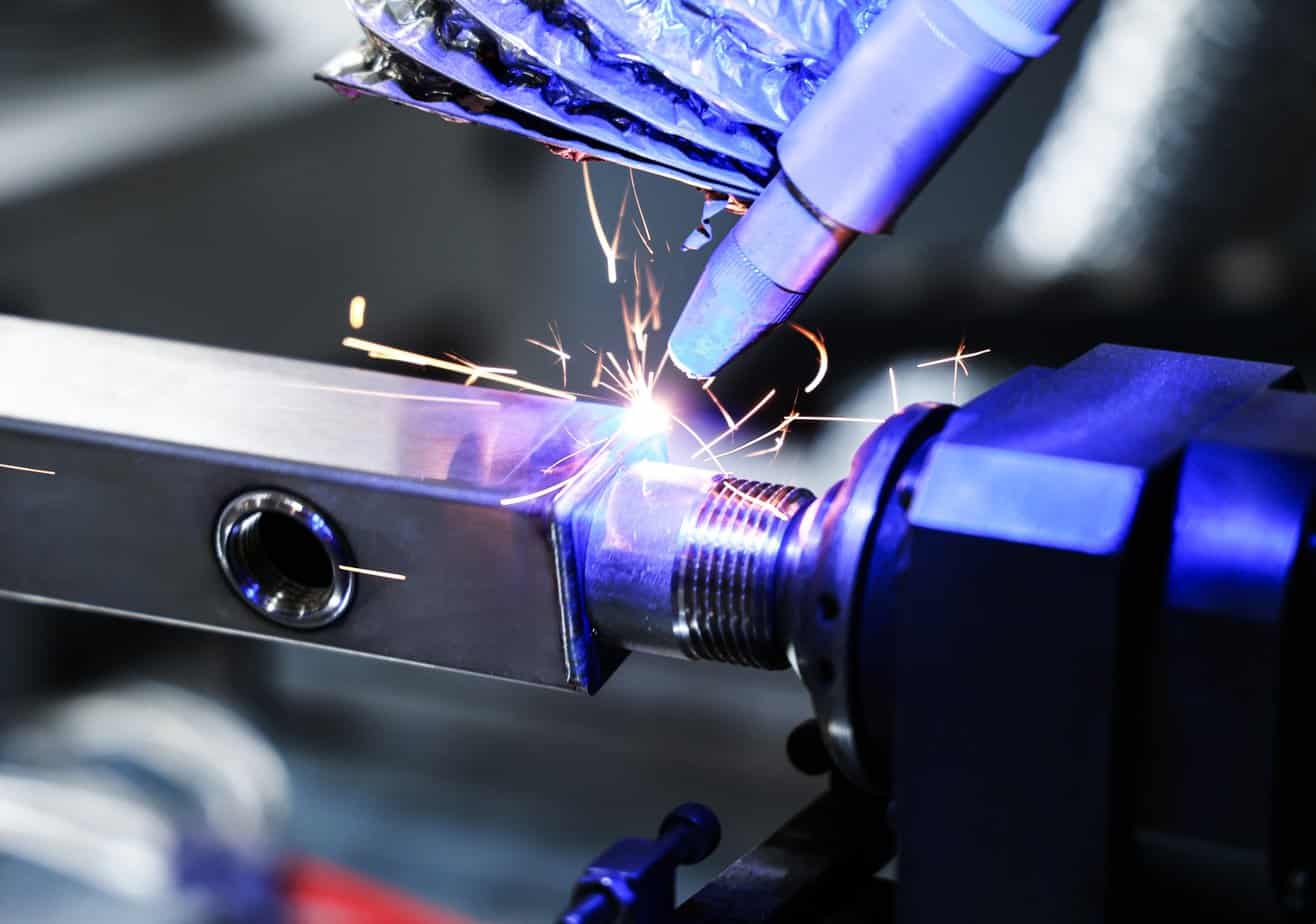

Interface processing utilizes a high-precision CNC lathe to produce threads, ensuring thread accuracy that meets the ISO 965-1 standard. Rotating parts are mirror-treated using special grinding equipment to enhance smoothness. Surface treatment utilizes an automatic pretreatment production line to complete degreasing and oxidation, followed by a multi-layer plating process (copper-nickel-chromium), with an intelligent plating bath to control uniform coating thickness.

Finally, the assembly welding is completed by a four-axis linkage argon arc automatic welding machine. The full-size detection is carried out by using equipment such as a three-coordinate measuring instrument and a thread gauge. Manual errors are reduced by relying on automatic equipment in the whole process, and the product size accuracy standard rate is stably above 99.8%, which completely meets the accuracy requirements of batch production.

5. What is the standard for Shower Swivel Elbow packaging?

Shower Swivel Elbow packaging strictly follows export transportation and industry standards, the inner packaging uses food-grade PE bag independent packaging, with EPE pearl cotton or foam liner wrapped, to prevent scratch coating or bump deformation during transportation; single or multiple combination packed in white box, color box or neutral kraft carton, box with product certificate and material description card, color box can print brand LOGO and product parameters (support multiple languages). The outer package shall be a five-layer corrugated carton that complies with GB/T 6543-2008, the export packaging standard. The carton shall be clearly marked (including name, specification, quantity, gross weight, destination, etc.) and reinforced with cross-packing tape or damp-proof wrapped film. For long-distance transportation such as sea transportation, we can also provide pallet packaging services (wooden pallets meet IPPC/ISPM 15 fumigation standards) to avoid damage; at the same time, we support OEM/ODM customized packaging, such as customer-specified brand packaging, gift box design or environmentally friendly degradable packaging materials, which fully meet the packaging compliance requirements and brand promotion needs of different markets.

6. Can you provide a proforma invoice (PI) and a commercial invoice (CI) for Shower Swivel Elbow?

Plumberstar can provide customers with proforma invoices (PI) and commercial invoices (CI) for the Shower Swivel Elbow throughout the process. The proforma invoice will be issued within 12 hours after the order is confirmed, clearly indicating the product name, specifications, quantity, Core information such as unit price, total amount, payment method and delivery date can be used for customers to apply for letters of credit, import licenses or internal approvals; Commercial invoices are prepared before shipment, strictly following customs declaration specifications, including detailed HS code (such as 8481.8000), country of origin, shipping marks, gross weight and other information, and consistent with documents such as bills of lading and packing lists. Invoice formats can be adjusted according to the customs requirements of customers ‘countries/regions to ensure smooth customs clearance. Both invoices are available in electronic and paper-stamped versions, which can be sent by mail or with the goods.

7. How many Shower Swivel Elbows can a 20-foot container and a 40-foot container hold by sea?

The number of shipping fashion cabinets should be determined in conjunction with the packaging specifications and loading methods of shower swivel elbows, using the conventional G1/2 interface brass model as an example.

If using “10 pieces/inner box, 50 inner box/outer box” packaging (outer container size 35cm×25cm×28cm), 20-foot container (internal volume of about 33.1 cubic meters, actual load of about 30 cubic meters) can carry 1200-1300 boxes, corresponding to the number of products 60000-65000;40 feet container (internal volume of about 67.5 cubic meters, actual load of about 60 cubic meters) can carry 2400-2600 boxes, corresponding to the number of products 120000-130000.

If compact packaging (20 pieces/inner box, 80 inner box/outer box, outer box size 40cm×30cm×32cm) is adopted, the 20-foot cabinet can be upgraded to 85000-90000 pieces, and the 40-foot cabinet can reach 170000-180000 pieces; the specific quantity will vary slightly due to product specifications (such as stainless steel weight increase, the total weight needs to be controlled), packaging customization requirements and loading methods. A professional cabinet packing scheme can be provided for large orders to optimize space utilization and ensure efficient storage.

8. Do you offer laser marking or casting logos on the Shower Swivel Elbow?

We offer laser marking and casting engraving, two types of logo customization services for shower rotary elbow products.

Laser marking is suitable for stainless steel, brass, and other materials. It features clear and fine marking, wear resistance, scratch resistance, no consumables, and high processing efficiency. It can accurately present brand identification, model specifications, certification information, and other content. It is suitable for small-batch customization or when a clear and sharp identification is required.

Casting engraving directly integrates the logo into the workpiece body in the product casting process. The emblem is firm and durable, with a heavy texture, and is seamlessly integrated with the product, making it suitable for large-scale, standardized production orders. Both processes can be accurately restored according to the LOGO vector diagram provided by the customer. The marking position and size can also be adjusted as needed. The specific process selection can be further communicated and confirmed with our process team, taking into account the order quantity, material characteristics, and brand display requirements.

9. Can you help reduce the overall procurement costs of the Shower Swivel Elbow for wholesalers?

We can reduce the overall procurement costs of shower swivel elbows for wholesalers through a multi-faceted approach, with the following core initiatives:

- Leveraging our large-scale production capabilities, we implement a tiered wholesale pricing strategy, where larger order volumes unlock more significant unit price discounts. Additionally, we offer extra quarterly or annual rebate programs to wholesalers who maintain long-term partnerships with us.

- We optimize our supply chain and logistics solutions comprehensively. Centralized raw material procurement helps lower production costs, factory-direct pricing eliminates markup from intermediate distributors, and we flexibly arrange consolidated container shipping or batch delivery based on total order volume to reduce per-unit logistics expenses.

- We support standardized customization and modular production, which avoids additional process costs caused by non-standard designs. Meanwhile, we provide free sample support and technical guidance to help wholesalers reduce trial-and-error costs.

- We deliver consistent quality assurance through full-cycle quality control measures, which reduce product after-sales repair rates and, in turn, lower the after-sales maintenance costs incurred by wholesalers.