FAQs of Shower Swivel Elbow

1. What scenarios are shower swivel elbows mainly used in?

Plumberstar’s shower swivel elbow can be used in many kinds of bathrooms. It works well in home bathrooms and is also suitable for large projects like hotels, apartments, and B&Bs. It is often used when fixing or improving shower systems, such as when the shower position is not right or the hose gets twisted. It can be used with different showers, including thermostatic showers and high-pressure showers. This product is widely used in new homes, old bathroom upgrades, and bathroom projects.

2. What are the advantages of Plumberstar’s shower swivel elbow?

Plumberstar shower swivel elbows are made of brass that meets NSF 61 lead-free standards. We use an integrated forging process to make them, so the valve body structure is dense with no blowholes. The surface is treated with multi-layer chrome plating. It has excellent salt spray and rust resistance, so it can be used reliably for a long time—even in humid or coastal environments with high salt spray.

The operation is smooth and easy. The elbow can be manually rotated 360° without jamming. It fits people of different heights and all kinds of shower postures, making adjustments a breeze. The internal flow channel is polished to be smooth and unobstructed. This not only reduces water pressure loss and keeps water flowing steadily, but also prevents the hose from twisting or knotting, effectively extending its lifespan.

For sealing and leak prevention, we use an EPDM sealing ring and a double-thread protection design. What’s more, every product undergoes a 100% water-pressure sealing test. It ensures no leakage under-rated pressure during the pressure holding process. We also fully check the rotation damping and sealing performance, so there’s no loosening or water leakage even after long-term use. Our product quality control is strict. Each product is shipped with a certificate of conformity and a parameter card, so the quality is fully traceable.

3. Has the shower swivel elbow passed the salt spray test?

Absolutely. We perform the ISO 9227 neutral salt spray test. The test runs continuous spraying in a 5% sodium chloride solution at 35°C for a full 480 hours. After the test, the surface has no rust spots, bubbles, or coating peeling—all up to the requirements of international standards like ASTM B117.

Plumberstar uses a multi-layer electroplating process for all our products: first, we plate copper on the brass base to boost coating adhesion. Then we plate nickel to form the core corrosion protection layer. Finally, we plate chromium to increase surface hardness and keep the surface bright and good-looking. Every plating layer has strict thickness standards to follow.

We can provide the complete test report, along with the goods, for you to check and for third-party institutions to conduct sampling inspections.

4. What is the shower swivel elbow manufacturing process?

The shower swivel elbow is made using careful machines and well-controlled steps from start to finish.

- First, brass rods are cut and shaped by automatic cold-heading machines. This helps form the basic shape accurately and reduces material waste, with over 90% of the metal being used.

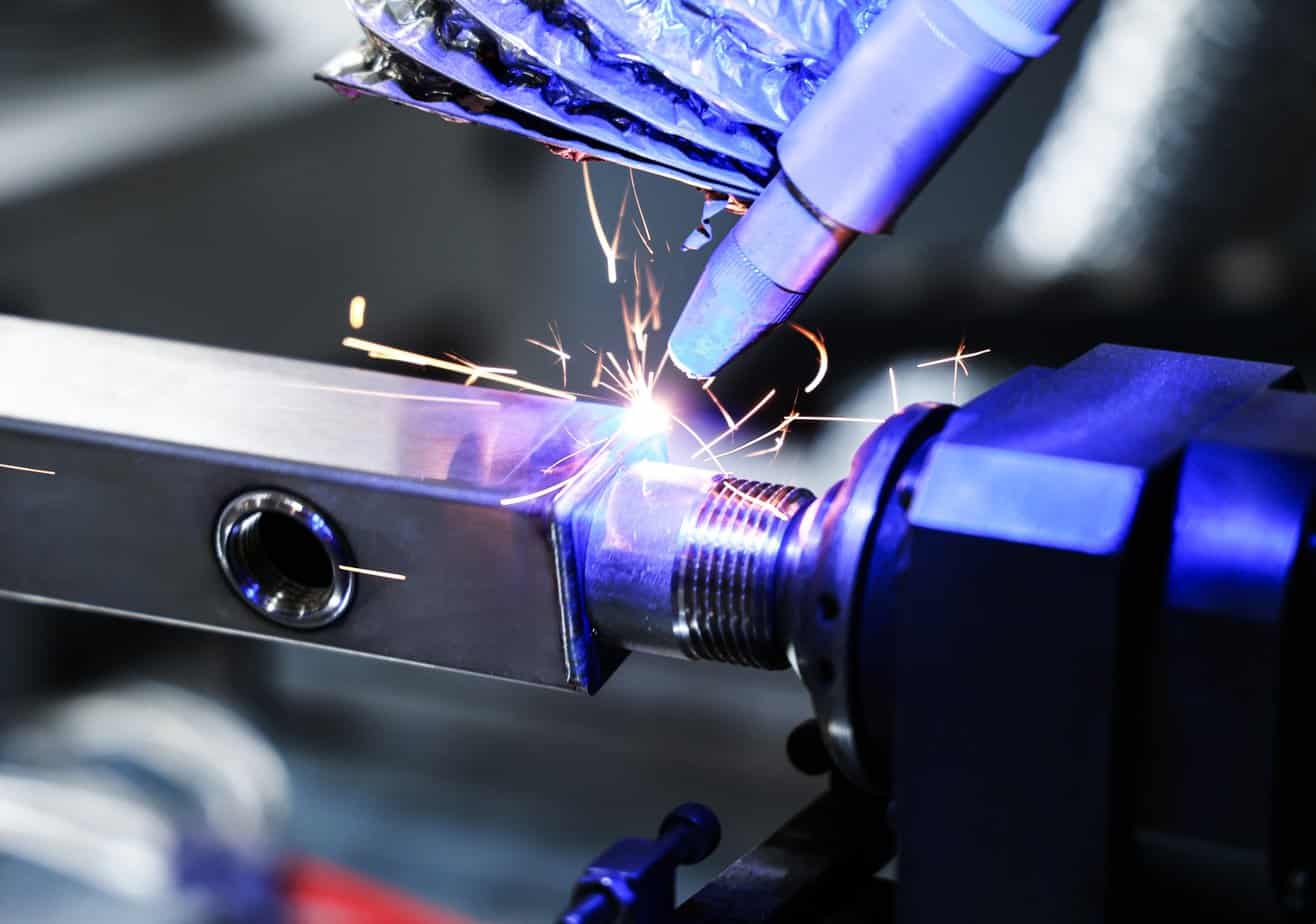

- Next, the main body is shaped by CNC hot-forming or cold-press machines, based on the material. An automatic pipe-bending machine bends the part to a 90° angle.

- Finally, automatic argon welding machines assemble the parts. Size and thread checks are done with measuring tools and gauges. Because most steps use machines instead of manual labor, mistakes are reduced, and more than 99.8% of the products meet size accuracy needs, which is very important for large orders.

5. What is the standard for shower swivel elbow packaging?

Inner Packaging: Every shower swivel elbow is first wrapped in a food-grade PE plastic bag, then covered with soft EPE foam or bubble wrap. This protects the product surface from scratches and stops damage from bumps during transport.

Products are packed individually or in small batches into white boxes, color boxes, or neutral kraft boxes. Each box comes with a product qualification certificate and a material card. Color boxes can be printed with your logo and basic product info, and we support multi-language printing too.

Outer Packaging: We use tough five-layer corrugated cartons that meet export standards. Clear marks are printed on the cartons—including product name, size, quantity, weight, and destination. Cartons are sealed with heavy-duty tape, and we can wrap them with moisture-proof film if needed.

6. Can you provide a PI and a CI for the shower swivel elbow?

Plumberstar can provide both a Proforma Invoice (PI) and a Commercial Invoice (CI) for Shower Swivel Elbow orders during the whole process.

After the order is confirmed, the Proforma Invoice is usually issued within 12 hours. It clearly lists the product name, size, quantity, unit price, total amount, payment terms, and delivery time. Customers can use the PI to apply for a letter of credit, import license, or internal approval.

Before shipment, we will prepare the commercial invoice. It will be declared in accordance with customs regulations, including information such as HS code (e.g., 8481.8000), country of origin, shipping marks, gross weight, etc., and will be consistent with the packing list and bill of lading documents.

Invoice formats can be adjusted to meet the customs requirements of different countries or regions. Both invoices are available in electronic and paper-stamped versions, which can be sent by mail or with the goods.

7. Can the shower swivel elbow be custom-logoed?

We provide two simple ways to add logos to shower rotary elbows: laser marking and casting engraving.

Laser marking works on stainless steel, brass, and similar materials. The logo looks clear and neat, does not fade easily, and is hard to scratch. It needs no ink or extra materials and is fast to do. This method is good for small orders or when you want the logo to look very sharp and clean, such as brand names, model numbers, or certification marks.

Casting engraving puts the logo directly into the product during the casting process. The logo becomes part of the body, so it is very strong and long-lasting. It has a solid, high-quality look and is best for large orders with the same design.

Both methods can follow the logo file provided by the customer. The logo position and size can also be adjusted. The final choice can be confirmed with our production team based on order quantity, material type, and how the brand logo should look.

8. Why choose Plumbersatr’s shower swivel elbow?

- First, we make products in large quantities, so we can offer step-by-step wholesale prices. The more you buy, the lower the price for each piece. For long-term partners, we also offer quarterly or yearly rebates, which help save even more money.

- Second, we manage our supply chain and shipping well. We buy raw materials in bulk to lower costs, sell directly from the factory without middlemen, and arrange shared containers or batch shipments. This helps reduce the shipping cost for each product.

- Third, we use standard designs and modular production, which avoids extra costs from special or complex designs. We also provide free samples and technical support, so wholesalers do not waste money on testing and mistakes.

- Finally, our strict quality control keeps product quality stable. This means fewer problems after sale, less repair work, and lower after-sales costs for wholesalers.