Description

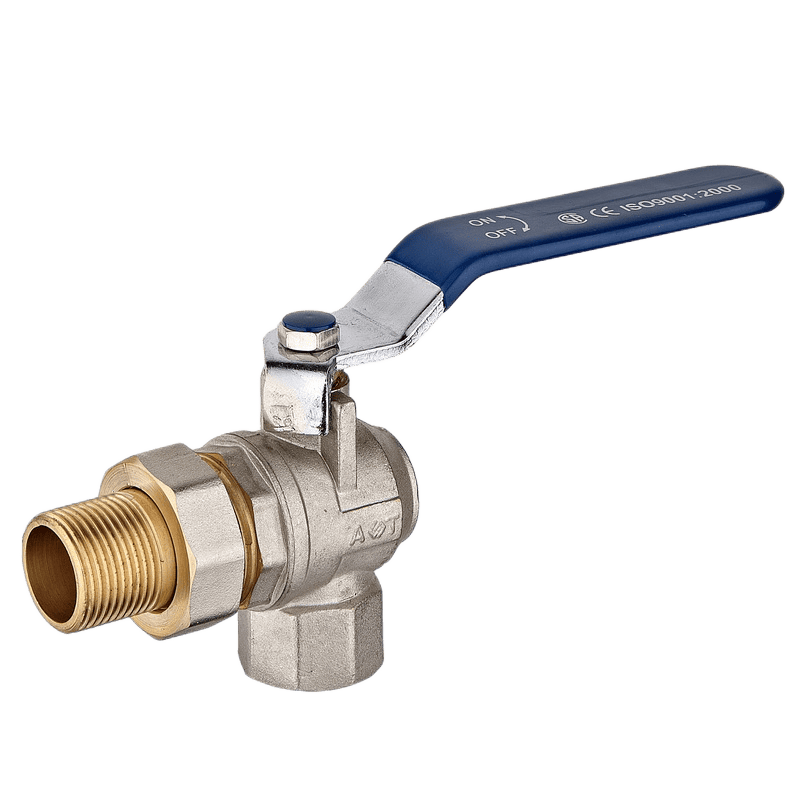

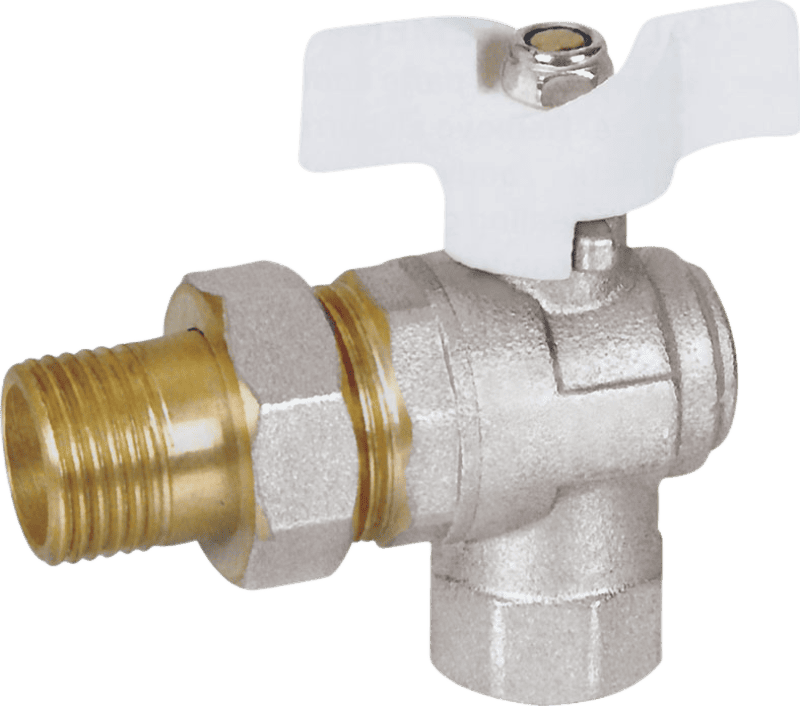

90 Degree Right Angle Ball Valve

JX-0424

- Product Features: Nickel-plated brass body and cover

- Chrome-plated Brass ball

- PTFE Sealing Ring

- Easy to install and operate

- Long service life

- Resistant to low temperature, humidity, and mechanical impacts

- Applications:cold-hot water installations, oil, and explosive gasses

- Temperature: Min. -10℃ / Max. +110℃

- Suitable for water supply systems, civil construction piping systems

90-degree valve closing range, the handle can close the valve by rotating it to either side of the valve body

What’s a ball valve?

A ball valve is a shut-off valve that controls the flow of a liquid or gas using a rotary ball having a bore. The medium can flow through or is blocked by rotating the ball a quarter-turn (90 degrees) around its axis. A long service life characterizes them and provides reliable sealing over the life span, even when the valve is not used for a long time. As a result, they are more popular as shut-off valves than gate valves. Moreover, they are more resistant to contaminated

3-way ball valve vs. 2-way ball valve: A 2-way valve is only suitable for on/off applications. The pipe is linked through two holes in a 2-way ball valve on each side. This valve has a single straight opening through which the media passes. In rare cases, variable flow systems include pressure, temperature, and flow variations. The 3-way ball valve uses one extra port. Pneumatic or electrical actuators can control 3-way valve assemblies, much as 2-way valves. These valves may divert fluid flow or mix fluids into a single exit from two inlets. Liquids from the intake ports are then mixed within the valve body. It is then transmitted through the exit port as a mixing valve. 3-way valves are far more cost-effective than many two-way valves. The effectiveness is due to the diverting and mixing. 3-way valves are ideal for heating and cooling various media. This media includes water, oils, and chemicals. It is possible by combining fluids from several inlets. These valves are often used as bypass valves in primary and secondary applications.

Uses of 3-way ball valve:

A Diverting, shut-off, and bypass are typical three-way multiport ball valve applications. These applications are with an L-type ball. T-type ball valves include sampling, mixing, bypass, purge, and uniform flow valves.

In the 3-way ball valve, flow deviates from one intake to two different destinations. It can restrict one outlet while enabling flow to continue in the other direction.

Combine two fluids from two separate sources. · It is a self-cleaning valve. Upon removing the valve from the seat, fluid washes away any accumulated dirt. It leaves the sealing surface clean.

It has a simple structure, a compact design, a small volume, and is light. It allows liquids to travel through the valve with little resistance.

A three-way ball valve operates in a simple internal design differentiation. The flow pattern or form of the port via the ball within the valve is an important design aspect. Flow-patterned valve balls with a capital L formwork in most 3-way ball valves have two flow routes or a capital T, with three flow channels.

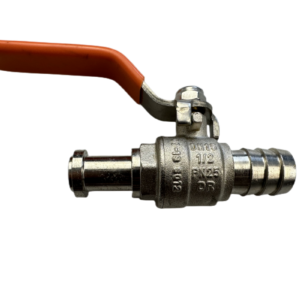

90 Degree Right Angle Ball Valve

The 90-degree right-angle ball Valve is a specialized valve that offers superior performance in tight spaces. It is often used to control water, oil, and gas flow in limited space or when other valves cannot provide the required flow rate. The right angle design means it can fit into even the most confined of areas, making it an ideal choice for many applications.

This valve has several advantages over other types of valves:

- Because of its unique design, it provides greater control and accuracy than traditional ball valves when controlling water pressure.

- Its streamlined shape allows for quick installation and low maintenance costs since fewer components are involved.

- This type of valve also features a smooth opening and closing action, which helps reduce wear on the internal parts and increase longevity.

Benefits: Compact Design, Space-Saving

Compact design and space-saving are two of the biggest benefits of using a 90-degree right-angle ball valve. When working in confined spaces, such as industrial pipes, these small size and tight radius designs offer an advantage that traditional ball valves can’t match. This type of valve features a body with a 90° bend to enable installation in tight spots, significantly reducing the total space requirements for flow control. The compact construction allows easy access to hard-to-reach areas while making it easier to monitor system performance or make repairs if necessary. Additionally, its reduced footprint minimizes pressure drop throughout the system by providing less resistance when controlling fluid flow. All these factors make this type of valve ideal for many applications where maximizing space is essential.

Types: Manual, Automated

Manual and automated 90-degree right-angle ball valves are preferred in many industrial applications. These valves have become increasingly popular due to their versatility, reliability, and cost-effectiveness. Manual models feature a hand wheel at the top of the valve to open or close the valve when needed. Automated versions also use a hand wheel and incorporate an electric motor or pneumatic actuator for remote operation. Both types offer reliable performance in various industries such as oil and gas, chemical processing, water treatment, etc. The manual model is ideal for controlling fluid flow on low-pressure systems, while automated variations are better suited for high-pressure situations where exact control overflow is required. Both options provide excellent pressure stability with minimal leakage even after repeated opening and closing cycles.

Applications: Industrial Piping Systems

Industrial piping systems are vital to many factory processes, efficiently transporting liquid and gas materials. These systems need to be constructed with the highest quality valves and fittings. The 90-degree right-angle ball valve is ideal for any industrial application because it can resist pressure, heat, and corrosion. This type of valve is renowned for its exceptional durability and reliable operation in even the most demanding industrial environments. With its unique design that allows easy installation and maintenance, this particular valve can provide a cost-effective solution to your industrial piping needs. It also has excellent sealing performance, perfect for controlling fluid flow and preventing leakage from piping systems. Installation of this item requires minimal effort and lower initial cost than other valves, making it a popular choice among valve manufacturers.

Installation Process

The 90-degree right-angle ball Valve is essential to your industrial process systems. Installation of this valve requires the utmost attention to detail and precision, as a successful installation will ensure the longevity and effectiveness of your system’s operation. Firstly, make sure that all necessary components are present before beginning installation. Ensure all mounting holes are correctly aligned and secure any other components (e.g., gaskets) needed for assembly before installation. Secondly, it is crucial to ensure that the ball valve’s orientation is appropriate for your system’s needs; proper orientation ensures that the fluid flow direction adapts correctly to pressure changes within the system during operation. Finally, position and secure any additional components.

Maintenance Tips for a 90-Degree Right Angle Ball Valve

Maintaining a 90-degree right-angle ball valve ensures its longevity and maximum performance. This type of valve is used in various applications such as chemical processing, HVAC, plumbing, and industrial manufacturing. To keep the valve in top condition, it’s important to follow these maintenance tips:

First and foremost, it’s essential to inspect the rubber seals regularly. Check for any signs of damage or wear that could lead to leaks or other problems down the line. Additionally, be sure to replace the seals when necessary; otherwise, you may experience significant issues in terms of functionality. Furthermore, check for clogs or obstructions regularly and remove them if needed.

Conclusion

Please get in touch with our team if you have any further questions or requirements. As a professional valve manufacturer-Plumberstar they are always reliable for water plumbing systems.

In conclusion, the 90-degree right-angle ball valve is a handy tool for anyone needing precise fluid flow control. Its simple design gives it tremendous versatility, and its remarkable accuracy makes it ideal for industrial and scientific applications. With the rising demand for this type of technology, the 90-degree right-angle ball valve will continue to be an invaluable tool in many different settings.