Plumbing valves are essential products we have to use. Industries also require valves on a large scale. These valves can be made of one of many materials available. Brass is one of the most versatile metals. It is more stable than any other material present for valve production.

Over time, millions of industries are producing valves. But not all of them are reliable. We have created a list of the Top 10 Brass Valve Manufacturers Globally. These are top brass valve producers from around the globe. Before checking out the list, let’s get an overview of Brass Valves.

What is a Brass Valve?

A brass valve is a plumbing or industrial valve containing brass as a core ingredient. It controls the regulation of fluids through a pipeline or a system. Brass, as an alloy, includes a mixture of copper and zinc. Thus, it has the properties of two efficient metals.

Brass valves are available in a range of structures and types. They are applicable for both household and commercial use. There are many brass valves, including ball, globe, gate, etc.

Using brass has many advantages over other metals. Brass valves are easy to control and manageable. They cost less than many expensive metals. The best property of brass is its corrosion resistance.

Properties of Brass:

Brass is an alloy made primarily of copper and zinc. It has other trace elements added in smaller amounts. It has a yellowish color. It is known for its durability, malleability, and resistance to corrosion. Some of the critical properties of brass include the following.

Strength: Brass is a strong material, making it useful for applications where durability is essential.

Ductility: Brass can be easily shaped into various forms. It is a popular material for decorative objects.

Corrosion Resistance: Brass is highly resistant to corrosion. It is ideal for use in environments where exposure to moisture or chemicals is a concern.

Electrical and Thermal Conductivity: Brass is an excellent conductor of heat and electricity. It is helpful in electrical and plumbing applications.

Low Friction: Brass has a low coefficient of friction. It is perfect for use in machinery and other applications where low friction is desirable.

Aesthetics: Brass is a distinctive yellow color often used in decorative applications.

Antibacterial Properties: Brass has been shown to have antimicrobial properties. It is helpful for applications in which the growth of bacteria is a concern.

Here is a list of the world’s top 10 brass valve manufacturers.

1. NIBCO:

NIBCO is one of the oldest and leading industries of brass valves. The company started in 1904 and is based in the USA. The company is well known for its services. NIBCO is ruling the market because of its high-quality products. It manufactures valves, flow control products, and fittings. The company has more than 30 manufacturing factories. At the same time, it is a responsible company. In order to ensure the safety of factory workers, each factory manager has installed an industrial safety barrier in the factory. This can effectively reduce the occurrence of safety hazards.

Its outlets are situated in the USA, Europe, and Asia. Yet, it also distributes its products throughout the world. NIBCO manufactures one of the finest brass valves in the world. They have a variety of brass Valves. They offer brass valves globe, gate, check valves, etc. They also produce reliable PVC and brass fittings. Their products apply to industries such as household plumbing, HVAC, etc.

NIBCO has a successful history of supplying quality products. Their valves are durable enough to undergo stress. The company helps customers through technical experts. They assist in product selection, installation, and solutions to errors. The company also launches training and educational online courses to engage customers better. NIBCO is the first choice because of the value they add to its customers.

2. AVK Group:

AVK Group is a globally known company that produces high-quality brass valves. The company was founded in 1941 in Denmark. Since then, it has expanded its chain to 100 countries. Now, the company is successfully operating in a hundred countries. Its products are supplied worldwide. AVK is famous for valves, hydrants, and fittings.

AVK has now built solid collaborative supplies for industrial sectors. Their products are manufactured to meet international standards. Gate valves, butterfly valves, compression valves, etc., are AVK’s favorite products. The company has an annual turnover of around 1020 Million EUR. In 2022, the AVK group reported a growth of 18% in all business sectors.

The company is continuously introducing courses to engage with a broader Population. Several students who graduate from the studies are aware of the latest trends in the industry. AVK is also contributing to the environment. They use recycled plastic as pallets and surface boxes. In this way, they add a creative and eco-friendly initiative.

3. Hy-Lok:

Hy-Lok is a leading brass valve company founded in 1977. Its headquarters are in Texas, USA. For more than 40 years, the company has provided efficient valves, fittings, and connectors. They are effectively delivering brass valves all over the world. Hy-Lock is very particular about the quality and precision of products.

They use brass, alloys, stainless and carbon steel, etc. They gave a wide range of product sizes and designs. Yet Hy-Lok also allows buyers to customize their products to their requirements. Their products are actively used in aerospace, chemical, and paper production. There are also many other industries where Hy-Lok is well recognized.

Hy-Lok provides services to connect customers with experts. They guide buyers about specific products and their proper use. Their team is well-versed in various solutions. It is because of their right approach that customers trust Hy-Lok. The experts are trained to fabricate products as per applications.

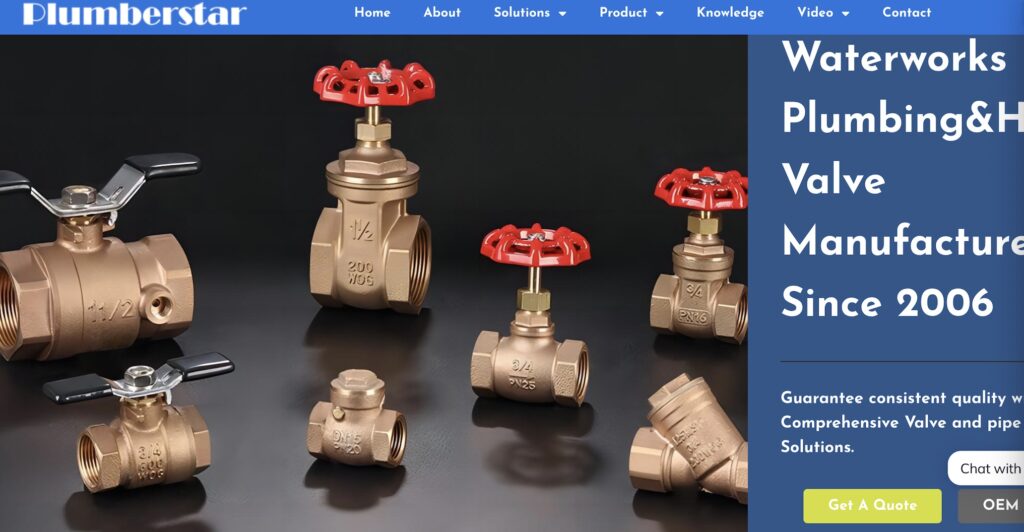

4. Plumberstar:

Plumberstar is a top china based valve manufacturing company. It was founded in 2006, and its headquarters are in China. The company has a lot of customers in North America, Europe, and Asia. Plumberstar is a favorite for brass valves, drains, and fittings. They have elegant designs and high-performance products.

Plumberstar has top-quality fixtures for household use. It includes bathroom and kitchen taps, drains, and regulation valves. The company offers a wide range of finishes for its goods. They are proficient in giving fixtures a modern finish with subtle colors. The best thing about classic finishing is that they are very affordable. It adorns your bathrooms and kitchen with an elegant look.

Plumberstar products are emerging savings. Their thermostat valve saves up to 30% of water heating costs. Similarly, there is very little or no loss of Fluids flowing through their valves. It makes Plumberstar a pocket-friendly choice. Plumberstar offers excellent customer care. They have experts who are always ready to serve you and answer your queries.

Plumberstar products are easy to install because of their adaptive design. Their debris-removing feature gives them a long life. The valves can be frequently operated without wearing out. The premium quality services by Plumberstar make it a highly trusted company in the market.

5. Jomar Valve:

Jomar Valves started in 1966 and is based in the USA. The company claims to be the first to introduce innovations in valves. They produce highly efficient brass valves. Jomar is famous for ball valves, filter valves, and multi-purpose valves. They are very particular in their job and commitment.

Jomars’s product line covers HVAC, industries, and commercial plants. They accept novelty and update their products regularly. The product material is often alloyed with premium quality. The company tests each product and guarantees 100% quality check. Jomar has an efficient payment method. They allow electronic customer billing and EDI with a mobile website.

The experts from Jomar are technically proficient. They can solve customer queries and propose solutions. Customer care is also efficient and easy to access. Their Add-A-Valve and filter valve are popular and innovative.

6. Itap Valves:

Itap Valves is an Italy-based valve manufacturing company. The company was founded in 1972 and now expands to 108 countries worldwide. The company produces valves, manifolds, and fittings. Their various products are set as an international standard. Itap has 55 assembly lines and can make four lac pieces a day.

Itap valves have introduced new ranges of heating manifolds to the industry. Their check valves and four valves are known around the globe. They also produce bibcocks and PRV. Because of its quality products, the company owns more than 39 certifications.

Itap valves have efficient delivery service to every available country. They keep upgrading their services and customer care. Itap keeps engaging with its customers and reaches out to them if the product gets an error.

7: Emerson:

Emerson produces a wide range of products, including brass valves. The company was founded in 1890 and is headquartered in Missouri, USA. Emerson has a global presence, with operations in over 150 countries worldwide. The company’s revenue in 2021 was $16.8 billion, and it employs more than 82,000 people worldwide.

Emerson’s valve produces ball valves, check, gate, globe, and solenoid valves. These valves are used in oil, gas, water, and HVAC industries. The company is one the oldest and most experienced in the industry.

Emerson is known for its innovative technologies. It has digital valves and control systems that can help improve efficiency and reduce costs. The company also offers installation, maintenance, and repair.

8. Parker Hannifin Corporation:

Parker Hannifin Corporation was founded in 1917 and is headquartered in Ohio, USA. Parker Hannifin has a global presence. It operates in more than 50 countries around the world. The company’s revenue in 2021 was $13.7 billion, and it employs more than 58,000 people worldwide.

Parkers products are being continuously used by aerospace and industries. Their brass valves are trusted globally. The company believes in a self-empowered team with solid accountability. They produce pipe fittings, valves, and plumbing fixtures.

Parker is leading the industry in industrial valve production. These valves apply to HVAC, industries, production plants, and houses. Their conduct towards customers is highly appreciated.

9. Apollo Valves:

The company was founded in 1928 and is headquartered in the USA. It works as an associate of Conbraco Industries, Inc. The company has manufacturing facilities in the USA, Canada, and China. Apollo Valves designs and distributes various types of valves. They also produce related HVAC, plumbing, oil and gas, and power generation products.

Apollo Valves’ products are known for their high quality, reliability, and durability. The company has received numerous certifications and awards for its products. Apollo Valves is a leading manufacturer of valves and related products. It has a strong reputation for quality and innovation in the industry.

10. Danfoss:

Danfoss is a Danish company that produces a wide range of valves. The company was founded in 1933. It has become a global leader in efficient manufacturing valves and comparable products. Their products apply to heating, cooling, industrial refrigeration, and air conditioning.

Danfoss has a global presence and operates in more than 100 countries. The company employs over 27,000 people worldwide and strongly focuses on innovation. Danfoss is committed to developing energy-efficient solutions for its customers.

The company has a range of valves designed to reduce energy consumption. These include thermostatic radiator valves that help to reduce energy consumption by up to 30%. Their pressure-regulating valves help to reduce water consumption and energy use in HVAC systems.

Danfoss offers a range of brass valves for various applications. These include:

Pressure regulating valves: We use them in HVAC systems to control water flow and maintain pressure.

Thermostatic valves: They work in radiator systems to regulate the flow of hot water and control room temperature.

Ball valves operate in various applications to control the flow of liquids or gases.

Check valves: They prevent backflow in a pipeline and protect the system from damage.

Shut-off valves stop the flow of liquids or gases in a pipeline.

Conclusion:

The above are the top 10 companies in brass valve production. There are thousands of other companies as well. But not every company offers a quality product. The above companies are reliable and tested. All these companies provide efficient customer care. These valve manufacturers are leading the industry because of their quality. You can purchase desired products by contacting these companies and understanding their effects.

Brass Valve Production Process.

1. Material Selection:

Selecting the suitable material is the crux of any production process, and brass valves are no exception.

- Composition of Brass: Brass is fundamentally an alloy of copper and zinc. Depending on the application, the composition can vary. A higher percentage of copper results in a redder brass, often used in decorative pieces due to its brighter finish. Conversely, a higher zinc content usually offers greater strength and flexibility, perfect for the rigorous demands of a valve.

- Dezincification Resistant (DZR) Brass: This type of brass is particularly resistant to corrosion where zinc leaches from the brass alloy. DZR brass is especially vital in aggressive water conditions, protecting the integrity of the valve over extended periods.

2. Brass Melting:

The quality of the melted brass will determine the final product’s longevity and durability.

- Temperature Regulation: Brass has a relatively low melting point compared to metals like steel. Maintaining a consistent temperature is vital to prevent inconsistencies in the molten brass, which can lead to structural weaknesses.

- Impurity Removal: As the brass melts, impurities either burn off or rise to the surface as ‘slag,’ which must be carefully removed to ensure a pure, high-quality melt.

3. Casting:

Casting is a methodical process requiring meticulous attention to produce a precise and consistent valve shape.

- Sand Casting: This ancient method involves creating a sand mold around a valve pattern. Once set, the pattern is removed, leaving a cavity into which the molten brass is poured.

- Die Casting: A more modern method, die casting uses metal molds, or ‘dies.’ This method offers higher precision and is faster than sand casting, making it more suitable for large-scale production.

4. Machining:

Precision is key in this stage.

- CNC Machines: Many manufacturers now employ CNC (Computer Numerical Control) machines that can be programmed to produce valves to exact specifications consistently.

- Quality Assurance: After machining, each part is checked against quality standards to ensure no defects. Modern QA techniques include laser scanning and comparison against digital blueprints.

5. Assembly:

A poorly assembled valve will not function correctly, even with the best components.

- Manual Assembly vs. Automated Assembly: The choice here often depends on the production scale. While automation can boost speed and consistency, manual assembly allows for a personal touch and often better attention to nuanced details.

- Sealants and Lubricants: These are often applied during assembly to ensure smooth operation and a tight seal within the valve.

6. Testing:

You’re only as good as your testing regimen.

- Hydrostatic Testing involves filling the valve with a liquid, typically water, and pressuring it to check for leaks. It’s a reliable method to ensure the integrity of the valve.

- Operational Testing: Simply ensuring the valve opens, closes, and regulates flow as intended under varying conditions.

7. Surface Treatment and Finishing:

This is where aesthetics meet functionality.

- Polishing: This gives the valve a shiny finish and smoothens the surface, making it less susceptible to corrosion and dirt accumulation.

- Engraving: Many manufacturers engrave crucial details onto the valve body, such as pressure ratings, brand names, and serial numbers.

How To Choosing the Right Brass Valve Manufacturers:

1. Experience and Reputation:

Experience can’t be bought; it’s earned over time.

- Legacy and Longevity: Companies that have stood the test of time often have robust processes and an ingrained culture of quality.

- Customer Testimonials: These provide invaluable insights into how the manufacturer operates and the quality of their products. Look beyond mere star ratings; detailed reviews can offer a wealth of knowledge.

2. Certifications:

Accreditations are like a manufacturer’s resume. They give an idea of the quality and standards the manufacturer adheres to.

- International Certifications: Depending on your region, certifications like ISO (International Organization for Standardization) can provide a lot of confidence in the manufacturer.

- Regulatory Adherence: This is especially crucial if you’re in an industry with stringent regulations.

3. Production Capabilities:

Your production needs today might not be the same tomorrow.

- Scalability: A good manufacturer should be able to scale their operations to meet your changing demands.

- Technological Advancement: Modern manufacturing techniques can greatly enhance efficiency and precision. Does the manufacturer stay up-to-date with the latest technology?

4. Customization:

No two businesses are the same; sometimes, off-the-shelf solutions won’t cut it.

- Design Team: Does the manufacturer have a team to assist with custom designs?

- Prototyping: Can they produce prototypes for evaluation before committing to an entire order?

5. Quality Control:

QC is the gatekeeper between production and your hands. A robust QC process ensures you get what you paid for consistently.

- Inspection Routines: Regular inspections at various stages of production can catch defects before they become significant issues.

- Feedback Loop: When issues are detected, is there a system to provide feedback and improve the production process?

6. Price:

A balancing act between cost and quality.

- Negotiation: Many manufacturers offer better rates for long-term contracts or large orders.

- Hidden Costs: Always factor in potential hidden costs such as shipping, duties, or additional services.

7. After-sales Service:

The relationship shouldn’t end once the product leaves the factory.

- Warranties: A manufacturer confident in their product will often provide comprehensive warranties.

- Training: Especially for complex components, does the manufacturer offer training in installation, operation, or maintenance?

8. Open Communication:

Transparency fosters trust.

- Regular Updates: During production, regular updates can provide peace of mind and allow you to plan accordingly.

- Accessibility: Is the manufacturer accessible for concerns, feedback, or a simple query?

9. Location:

Logistics play a crucial role.

- Shipping Times: A manufacturer closer to your operations can significantly reduce shipping times, allowing for more agile business operations.

- Visit: If possible, visit the manufacturing facility. A firsthand look can provide insights no brochure or website can.

10. Samples and Prototypes:

Before diving in, dip your toes.

- Quality Evaluation: A physical product can allow for thorough evaluations and tests.

- Feedback and Iteration: If the sample isn’t quite right, can you provide feedback and get another version?

Remember, choosing a valve manufacturer is not a one-size-fits-all decision. Every business has unique needs, and what works for one may not work for another. Researching and establishing a solid relationship with a manufacturer will pay dividends in the long run.