Valves are mechanical parts that can open, close, or stop the flow of water in some way. They are used to control, direct, and manage how water flows. You can make them from bronze, PVC, brass, and other things. Valves are used in homes, businesses, water systems, wastewater treatment plants, and chemical plants to control water flow, shut off water access, stop backflow, and change the water pressure within a system. A valve is a mechanical expedient that controls how fluid moves through a system or process and how much pressure it has. So, it controls how much flow and pressure there is.

Types of valves used in House Supply

- Gate Valve

- Ball Valve

- Globe Valve

- Check Valve

- Fixture Shutoff Valve

- Faucet Valve

- Pressure Reducing Valve

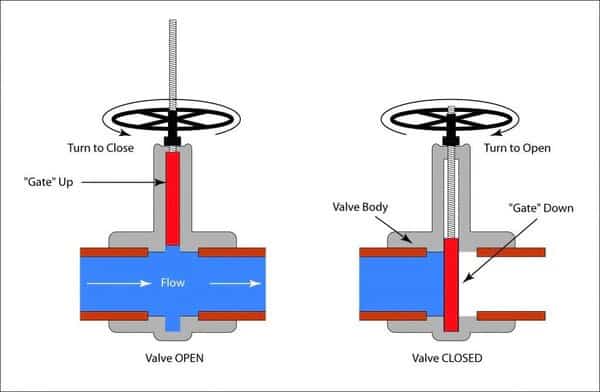

Gate Valve

The most common type of valve in plumbing systems is the gate valve. It has a metal gate in the shape of a wedge that can be moved up or down with a twist-type handle or knob to stop or start the water flow. Gate valves cannot control water flow because they can only be fully open or fully closed. It can wear out the valves to change how much water is flowing. Gate valves control airflow, fuel gas, feed water, steam, lube oil, and hydrocarbons, among other fluids.

Types of Gate Valves:

- Solid taper wedge: The split wedge disc is made of two solid pieces held together by a unique system. The disc can move to fit the surface it is sitting on. The shape of the partition disk can be a wedge or a parallel disk.

- Flexible wedge: The flexible nail is a solid disc made of one piece with a cut around the edge.

- Split wedge or Parallel disks Valve: Because it is easy to use and strong, the solid wedge disk is the most common and widely used type.

- Screwed Bonnet: The simplest design is used for cheap valves.

- Bolted bonnet: The joint between the body and the bonnet must be sealed with a gasket.

- Welded-Bonnet: This popular design doesn’t need to be decompressed.

- Pressure-Seal Bonnet: This type is used a lot in high-pressure, high-temperature situations

- Rising Stem or OS & Y Type (Outside Stem and Screw Type): When you open a mounting stem valve, the stem will move up. When you close the valve, the stem will move down. This is clear from the picture.

- Non-rising Stem type: The stem does not move upward in the growing stem. The inside of the valve disc has threads. In this plumbing valve, the thread on the stem is exposed to the fluid.

Application of Gate Valves

- Most fluids use gate valves, such as air, fuel gas, feed water, steam, lubricating oil, hydrocarbons, and most other services.

- Some special gate valves, like knife gate valves, are also used in slurry and powder products.

Advantages of Gate Valves

- Because the valve opens and closes slowly, the water pressure changes slowly, which keeps the pipe from making a banging sound from the water hammer.

Disadvantages of Gate Valves

- The valve’s seat can wear down over time, weakening the seal and lowering the valve’s effectiveness.

- The only way to raise or lower the valve is by hand, which can take a long time.

Ball Valve

The ball valve is the most reliable and common type of valve to control the water flow. The valve is turned on and off by turning a sphere with a hole in it that is attached to a lever handle. When the valve is open, the hole in the sphere lines up with the pipe, letting water flow through it. When the valve is locked, the hole in the sphere is perpendicular to the pipe. This makes it impossible for water to flow through. The valve is shut when the lever is straight with the pipe.

Types of ball valves:

- Floating: The floating ball valve has two elastomeric seats that press against the ball and keep it in place. Look at the part of the picture that is highlighted and remember it. You will see the difference when you tell me about the trunnion-mounted valve. The stem is connected to the ball by a slot at the top, which lets the ball turn a quarter of a turn. The pressure going up on the ball makes the ball move to the side a little bit, which is allowed by the shaft. This small movement to the side puts pressure on the ball, which presses it against the seat downstream. This makes the valve leakage tighter. When the pressure going up is high, it is tough to move the floating valve.

- Trunnion Mounted: A trunnion is a small shaft or extension set in the body. You can tell from the picture. In this design, the steam and the ball work together. The ball is held up by two seats that float or are loaded with springs and are always in contact with the ball.

- 3 Way: You can set up a three-way valve port based on your needs.

– One intake and two outputs

– A flow can be changed with an inlet and an outlet.

– Fluid goes straight through without going in.

Advantages of Ball Valves

- When they are closed, they make a great seal.

The disadvantage of Ball Valves

- Ball valves aren’t suitable for controlling flow precisely because they usually have hard stops (0, 45, 90 degrees).

Globe Valve

In plumbing, where water flow needs to be changed often, the Globe valve is often used to control or limit the flow. Globe valves are called that because their bodies look like globes or balls. The globe valves can be used to control water flow, and they are often found on hose bibs and other outdoor utility faucets.

Globe Valves type:

- Z types Globe Valve: Z-body cars are the most common and easiest to make. Inside the round body of the Z-shaped partitions are seats. Because the seat is set up horizontally, the stem and disc can move in a way that is not parallel to the axis of the pipe. This causes too much pressure.

- Y types Globe Valve: The Y-type design can fix the high-pressure drop in Z-type valves. This type’s angle between the pipe axis, seat, and stem is about 45 degrees. This kind of valve is used in high-pressure services and other essential situations where pressure drop is a problem.

- Angle types Globe Valve: The angle globe valve can change the flow direction by 90 degrees without using an elbow and a second pipe weld. Open the disc against the flow. Globe valves can also be used in changing conditions because they can handle the slugging effect.

- Screwed bonnet type: This is the simplest design used for valves that don’t cost much.

- Bolted bonnet: This is the most common style, and it uses a lot of globe valves. The connection between the body and the bonnet must be sealed with a gasket.

- Welded-Bonnet type: This common design doesn’t need to be taken apart. They are lighter than their counterparts with bolt bonnets.

- Pressure-Seal Bonnet type is widely used in high-pressure situations and high temperatures.

Uses of Globe Valve

- It is used in low-point drains where safety and lack of leaks are very important. If not, you can drain and vent with a gate valve.

- It can feed water, chemicals, air, lubricating oil, and almost any other service where pressure drop is not a problem.

- This valve can also be used as an automatic control valve.

Advantages of Globe Valves

- Globe valves are used where the flow needs to be changed often but don’t need to be fully open.

Disadvantages of Globe Valves

- Since the baffle slows the flow, globe valves can’t be used when fully open.

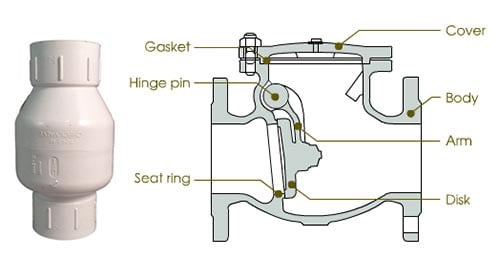

Check valve

A check valve is a plumbing valve that keeps water from going backward through a pipe system. It is also called an NRV, which stands for “non-return valve.” The pressure of the fluid moving through a pipeline opens the valve. If the fluid flow goes in the opposite direction, the valve closes.

Types of Check Valves

- Swing Check Valve: When a swing-type valve opens or shuts, the discs inside lock together. When there is flow in the line, this valve opens and closes. When there is no flow, it stops completely. The flow of air and the drop in pressure in the valve are very low. Metal-to-metal or metal-to-metal designs can be used for the disc and seat.

- Tilting Disc Check Valve: Traditional swing-type valves have some flaws that tilting disc-type valves are made to fix. Because of how the tilting disc is made, the valve can fully open and stay stable at low flow rates. When the forwarding flow is stopped, the valve can close quickly.

- Dual Plate / Dual Disc Check Valve: People also call a dual plate check valve a butterfly check valve, a folding disc check valve, a double-disc check valve, or a split disc check valve.

- Stop Check Valve: It can be used like a globe valve as either a check valve or a stop valve.

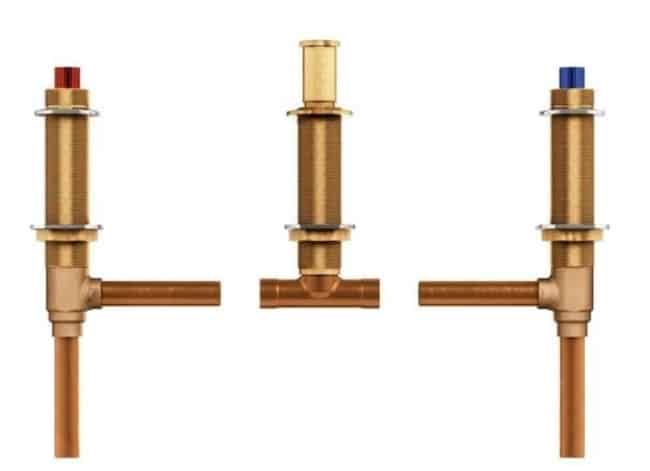

Fixture Shutoff Valve

Under-sink valves, also known as fixture shutdown or stop valves, contain a knob or handle that can be moved to regulate water flow in plumbing fixtures such as the sink, toilet, and faucet. Other names for these valves include stop valves and fixture shutoff valves. Some are perpendicular to the ground and have an angle of ninety degrees.

On the outside, shutoff valves for fixtures resemble miniature gate valves because they typically include a small knob or wheel that can be twisted to open and close the valve. This gives them the appearance of gate valves. On the interior, shutdown valves for fixtures can be fabricated with various patterns and designs.

Some people employ a straightforward washer that can move up and down against a valve seat in response to the movement of the valve handle. The diaphragm is used in the construction of the others. The flow of water is stopped via a flexible diaphragm controlled by the valve stem. This diaphragm presses down on an aperture in the valve seat.

Faucet Valve

Even though they come in a wide variety of designs, faucet valves all have the same purpose: to regulate the amount of water that flows through a sink, bathtub, or shower. There are a few different kinds of faucet valves, which are as follows:

- Ball valve type: These are straightforward and dependable mechanisms that either turn the water on or off and provide little room for managing water flow. Ball valves are an example of this sort of valve.

- Cartridge valve type: The cartridge valve is the most popular shower valve. It controls the water flow by rotating to either open or close the passageway leading to the showerhead. Cartridge valves can also be found in bathtubs.

- Ceramic disc valve type: Ceramic disc valves are a type of valve characterized by two ceramic disks that rotate in opposition. Water can flow through the valve if the holes in the upper and lower disk are properly aligned. However, if the holes are not properly aligned, the flow of water will be impeded or stopped entirely.

- Compression valve type: Compression valves are the sort of valves described here. These valves use a rod and plug to seal a hole referred to as the valve seat.

The only conventional application for this kind of valve is to regulate water flow from a sink’s faucet; however, they can also be used on the water lines leading to appliances.

Pressure Reducing Valve

Water pressure-reducing valves are put in place to ensure that the total water pressure in a plumbing system stays within acceptable limits.

They typically consist of a spring and a diaphragm that can be fine-tuned to fit within a particular limit, which is determined by the pressure of the water supply. Installing them in residences serviced by municipal water supplies that deliver water at rather high pressure is the usual practice. This is because the pressure may be sufficient to cause damage to the plumbing systems and appliances inside the home.