Gate and ball valves are the market’s most commonly used flow control valves. People generally use them to control the flow of liquids and gases. These valves serve a similar function.

However, there are main differences between them. While there’s a wide range of valve varieties, the ball and gate valves are the most popular.

Both valves perform a similar purpose. However, their structural features reveal significant differences. This post explains the gate valve vs ball valve and how to decide which one to choose.

Before moving to gate versus ball valve difference, it’s vital to know about their basic; let’s go.

What Is a Ball Valve?

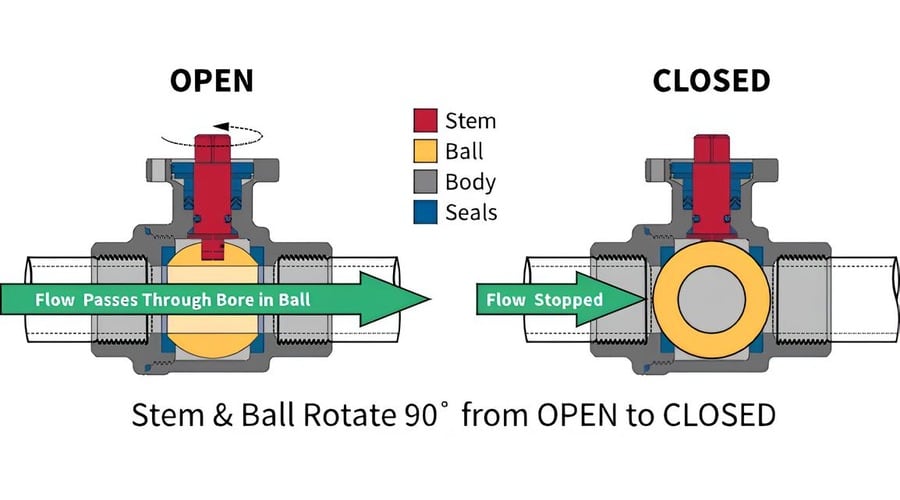

A ball valve has an opening that can turn, and a ball controls the flow of gas or liquid from one end to the other. It can let the medium run through or stop it by turning the ball 90 degrees, which is one-quarter of a turn. These gates control the flow by permitting the flow through or blocking the opening.

How Does Ball Valve Work?

It works in a way that is similar to the butterfly valve. It comprises a ball with a hole bored through the middle of it, where the spherical opening determines whether the flow is open or closed. The stem connects to the tool’s handle or actuator, and the ball connects to it. To start the fluid flow, the actuator turns about 90 degrees backward. It turns the stem, which makes the ball spin.

This kind of shutoff valve allows fluid to move through when the ball’s orifice aligns with the fluid passage. The actuator turns 90 degrees counterclockwise. The stem turns the same flow path as the ball turns 90 degrees counterclockwise, and the flow of fluid stops.

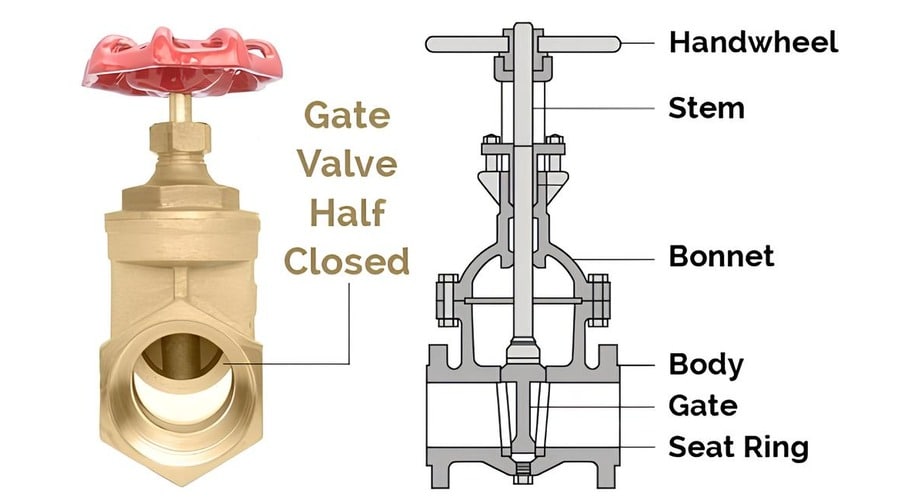

What Is a Gate Valve in Plumbing?

A kind of valve that restricts the passage of fluids. The pressure over the valve is slightly lower because of the clear passage flow. The gate valve’s open bore allows water to flow through lines to clean them. Because they turn more slowly, gate valves are better when fully open or closed.

How Does a Gate Valve Work?

It controls fluid flow by moving a gate inside the valve body. Connecting the gate to a threaded stem or handwheel that enables manual operation is common. The valve seat, body, gate, and stem are according to their order of importance.

Fully open gate valves completely raise the gate, permitting unrestricted fluid flow. In contrast, when you completely close the gate valve, the gate fixes against the valve seat and impedes the passage of fluids.

A water gate valve effectively controls the flow of water, allowing for easy stopping or starting of the flow. This is because of its ability to control the flow of water completely.

Gate Valve Vs. Ball Valve: Main Differences

Here, we will discuss both valve functions to help understand the difference between gate and ball valves.

Valve Design and Construction

Regarding liquids and gases, sluice valves are more frequently used than ball valves. This valve controls fluid flow with a ball. Conversely, gate valves employ a circular gate for the identical function. However, both valves have their uses, advantages, and disadvantages.

Valve Flow Direction

Because of their design and operation, we know how gate and ball valves work and their flow direction. Choose a gate valve for a system that blocks the flow in one direction. Additionally, gate valves work well when a lot of fluid needs to move through quickly.

Ball valves work better when flow passes in both directions. Ball valves are easier to use than gate valves. Therefore, they are a good choice when opening and closing the valve.

Operation Differences of Gate and Ball Valves

The main difference between the gate and ball valve is the operation difference. An integral part of a ball valve is a stem and a rotary ball. Rotate the stem-attached handle to open or shut the valve, which will rotate the ball. They call this valve a quarter-turn valve.

It only needs a quarter turn to open or close the handle. The handle turn is equal to 90 degrees. The handle parallel to the pipe opens the valve while having it perpendicular to the pipe closes it.

A gate valve controls the flow of media using a gate. The gate is connected to a solid disk structure by a stem. To open the valve, raise the gate and close it back to its original position. The valve has a bonnet attached to it that can be turned to move the gate.

This valve needs more than one full turn to open or close, so it’s called a multi-turn valve.

Ports

Ports are another main factor in the differences between gate and ball valves. Ports define the openings and closings of a valve. Only two ports on a sluice valve means it can work in both directions. The holes’ threading, bonding, or flanging depends on the sluice valve type and use.

On the other hand, ball valves can have more than one port. These holes may have threading, bonding, or flanging based on the type and use of the valve. Different materials can move in different directions with the help of ball valves that have three holes—the number of holes in a valve and their size and purpose matter.

The full port ball valve has a hole that matches the size of the connected pipe. A ball valve with a lowered port has a ball with a hole size smaller than the pipeline.

Valve Seal Capacity

How do you know if a valve is open or closed? The gate valve tight seals completely when closed. It makes it ideal for high-pressure applications. Additionally, it is suitable for situations that require a waterproof seal.

Ball valves have a gap in the center, allowing them to open and close quickly. But this also means they are less effective at sealing under high pressure.

Gate valves are more common since they are less expensive and simpler to maintain than ball valves. On the other hand, ball valves can withstand greater pressures but come at a higher initial cost and are more difficult to replace.

Durability

Gate valves usually last longer than ball type valves because they have fewer moving parts and are less likely to rust. Ball valves can leak over time, but they might be easier to fix if they do.

It’s up to the individual to decide what kind of valve to use. You should get a valve that can handle a lot of wear and tear. A gate valve is a good choice. A ball valve might be better if you care more about how easy it is to fix.

Space

The area of operation needed by ball valves is more prominent despite their diminutive size compared to gate valves. The only way to turn a manual gate valve is with a small handwheel, but a manual ball valve needs a 90-degree lever.

Wing or round-style handles are two examples of compact form factor substitutes for certain standard ball valves. These handles work well for small pipes, but they don’t give enough power for ball valves of significant size.

Gate Valve Vs. Ball Valve: Common Applications

-common applications

Many domestic and commercial uses exist for plumbing ball and gate valves.

Gate valves are used in slurries and dense media applications because they are easy to clean and maintain. People use gate valves in high-heat and pressure applications, such as water treatment, power plants, and mining. Slurry particles imperil rotating balls, making ball valves unsuitable for these conditions.

Older plumbing systems and uses that do not need frequent shutoff valves often include gate valves. People use gate valves because large water supply pipes have fewer obstructions and allow water to flow straighter. Shutoff ball valves are becoming more common for modern plumbing systems that often need to shut off.

Fire protection systems and marine applications use ball-type valves. Don’t use in food, drink, or pharmaceutical industries applications, as they cause contamination.

Gate Vs. Ball Valve: How to Select?

There are many differences between gate valves and ball valves to consider. Here are some of the most important factors for selection:

Flow: Gate valves can handle more flow than ball-type valves.

Temperature: Ball valves can handle higher temperatures more effectively than gate valves.

Space: Ball-type valves are smaller than gate valves.

Pressure: Both valves can handle high pressures, but gate valves work better when the pressure increases.

Considering these criteria, ball valves are usually the best choice for low-pressure, low-temperature situations with limited space. Gate valves work best where flow is more important than room, like in high-pressure and high-temperature situations.

Which Is Better, The Ball Valve Or The Gate Valve?

It is application-dependent. If you’re concerned about sealing or longevity, have a lower flow rate, or need more than two ports, a ball valve is the way to go. Consider a gate valve if you’re looking for a cheaper, better, and more space-efficient option for more significant flow rates.

What Is The Difference Between A Ball Valve And A Gate Valve?

There is a significant distinction in the operation. An irrigation gate valve opens and closes an opening by raising and lowering a solid disk. When you turn the handle of a ball valve, it opens and closes by rotating a ball—the orifice—with a hole in it 90 degrees.

What Is A Ball Valve Used For?

It is common practice to utilize a ball valve as a shutoff valve because of its ability to regulate flow.

A Gate Valve Works In What Condition?

Applications with slurries, high flow rates, cost sensitivity, and shutoff needs are perfect for gate valves.

Wrap Up with Gate Valve Vs Ball Valves

In summary, we found that the main difference between them is operational difference. Ball valves can be partly open to control flow, while gate valves can only be fully open or the valve is closed. Moreover, gate valves are cheaper and easier to fix than ball valves. Ball valves, on the other hand, last longer and are less likely to leak.