What is a strainer?

A strainer is a pipe fitting that liquid flows through to clean, filter, or separate it from solids. It can also strain the liquid or any device that acts as a sieve or filter to keep solids from mixing with a liquid stream or flowline. Strainers catch scales, rust, dovetail joints compound, and weld metal in pipes. It protects machinery and processes from their harmful effects and reduces downtime and maintenance.

To protect expensive and essential equipment like pumps, flow meters, steam traps, control valves, etc., you must use the proper strainers in the right places (usually upstream).

Types of Plumbing Strainers

Plumbing strainers play a pivotal role in maintaining the efficacy of fluid systems. They prevent debris and foreign particles from infiltrating and causing damage or blockages. Their importance is underpinned by the myriad of types available, each tailored for specific applications. Let’s explore these strainers in depth:

Y-Strainers:

Description: A Y-strainer is aptly named for its resemblance to the letter ‘Y’ when viewed from the side. Its design is simplistic yet highly functional. At its core, a mesh or perforated filtering screen captures and holds unwanted particles as fluids traverse through. The construction allows for a smooth flow while ensuring filtration. Its design also facilitates easy removal and cleaning of the screen, promoting longer service life.

Applications: Y-strainers are versatile and integrate well within numerous setups. Regardless of industry, they’re primarily deployed in vertical and horizontal pipeline systems. From petrochemical plants to domestic water systems, the Y-strainer is a silent workhorse ensuring contaminants stay at bay.

Basket Strainers:

Description: As the name implies, a basket strainer has an internal basket-shaped mesh or perforation. This basket captures debris and is easily accessible for regular cleaning or replacement. The design emphasizes maximizing the surface area for filtration, ensuring a higher debris-holding capacity.

Applications: Primarily suited for liquid pumping systems, basket strainers find their place in settings where substantial amounts of debris are anticipated. They are common in manufacturing facilities, power plants, and even upscale residential properties with extensive plumbing.

T-Strainers:

Description: T-strainers, similar in naming convention to their Y-counterparts, mimic the letter ‘T’ shape. Though not as widespread as Y-strainers, they are purpose-designed for specific applications, primarily where contaminants are known to be abundant.

Applications: Their stronghold is predominantly within industrial settings. Due to their design, they are adept at handling high-contaminant scenarios, making them invaluable in sectors like wastewater treatment or chemical processing.

Cone Strainers:

Description: Crafted predominantly from mesh, cone strainers adopt a conical shape. Their purpose is temporary but invaluable during specific operational phases, particularly during system startups.

Applications: Their utility shines when a system is initiated, capturing construction remnants or residual debris within the line. Consider them the initial guardians before regular strainers take over the long haul.

Duplex Strainers:

Description: A feat of design, duplex strainers host twin baskets within. This double-barreled approach ensures no disruption in the operation, even during maintenance phases.

Applications: They are the filter of choice for systems that cannot afford downtime, like cooling or fuel lines in critical infrastructure.

Plate Strainers:

Description: Simplistic in their make, plate strainers are essentially perforated plates that facilitate fluid flow while straining out the larger debris.

Applications: Ideal for larger pipelines and ducts, they play a pivotal role in industries where the quality of the fluid can be compromised by larger debris, such as in agriculture or specific manufacturing processes.

Inline Strainers:

Description: As direct as their name suggests, inline filters are positioned right within the flow line. They are the embodiment of efficient design combined with practical functionality.

Applications: Their range of applications is vast, from domestic plumbing setups to specialized industrial processes. Their primary job remains consistent: ensure that the fluid flows free of contaminants.

Foot Valve Strainers:

Description: Foot valve strainers multitask at the bottom of the suction lines. Not only do they strain out debris, but they also play a pivotal role in preventing backflow.

Applications: Their value is unmatched in pump systems and similar machinery where maintaining a prime is crucial for efficient operation.

Y Type Strainers

The filter leg of a Y-type strainer connects to the main pipe at an angle, giving the filter its “y” shape and name. This type is often used in lines with pressure, such as steam, liquid, gas, vacuum, or suction.

Y-shaped strainers usually can’t hold as much dirt as basket-shaped filters, so they must be cleaned more often. It is usually not a problem on steam systems, except when rust or debris can get in right after the system is turned on.

Specification of Y Type Strainers

| End Connection | Flanged or Threaded |

| Size | 0.5-inch to 24-inch |

| Filtration Rating | 1 micron to 1000 microns |

| Pressure Rating | Up to 100 PSI |

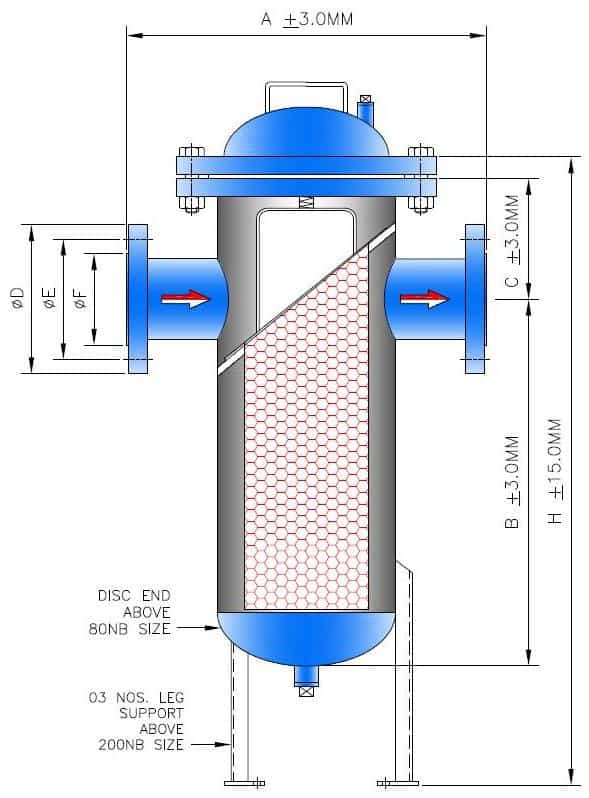

Basket Type Strainers (T-Type)

This filter works best with large particles and pipes that must be cleaned often. Most of the time, basket strainers are used at pressures above 1,500 PSI. This strainer has been given different names, such as the tee, T, or pot types. Also, the basket-type strainers lower the pressure less than the Y-type strainers.

This filter has a more extensive straining area, meaning it can hold more particles. The other benefit of this filter is that it can save more debris, so it won’t need to be cleaned as often. One problem with the basket-type strainer is that it can only be put in pipes that run parallel to each other.

Also, the base of the strainers must be strengthened for the bigger basket strainers. The basket strainers have a cover at the end that can be removed to make the filtering element easy. This makes it easy for them to change the filter or clean it when it gets full of debris.

Much condensation is collected when this strainer is put into the steam system. A drain stopper and a steam trap on the steam strainers catch the droplets.

Specification of T-Type Strainers (Basket Type)

| Pressure Rating | 125 PSI, 150 PSI |

| Size Range | 40mm (1½”) To 300mm (12″) |

| Body | Brass |

Application of T-Type Strainers (Basket Type)

Basket strainers can only be put on parallel pipes, and the base of a larger, bulkier basket strainer must be made stronger.

The basket strainer’s cover can be removed so that the filtering part is easy to get to if it needs to be changed (due to stocked-up debris). When basket-style strainers are used on steam systems, they can collect a lot of condensates. So, steam strainers usually have a stopper for the drain and a steam trap to catch the droplets.

Duplex/Twin Strainer

As the name suggests, the duplex or twin strainers use two strainers to do the job. This is also a basket strainer, but it is called something else. When many things happen simultaneously, and it’s hard to clean between processes, the duplex filters are a good choice. When you have two strainers, the straining process can be moved to the other basket when the first one is complete.

So, the strainer ensures the filtering process will continue until the first basket is cleaned or replaced. This filter has either plug-type valves or ball-type valves. This makes changing the water flow from one basket to another possible. These filters can only be put in pipes that are parallel to each other.

Also, they are great for pipes that are big or bulky. These filters are also great for pipelines or programs that must run constantly. When one basket gets full, the other is ready to take over.

Specification of Duplex/Twin Strainer

| Pressure | Up to 2500 psi |

| Temperature | Up to 560 0C |

| Mesh size | 37 – 6730 microns or Mesh 3 – 400 (US) |

| Material body | Iron, Bronze, Carbon Steel, and Stainless Steel |

| Material mesh | Stainless Steel |

| Connection | Flange Flate Face (FF) & Raised Face (RF), Ring Type Joint (RTJ), Threaded, Buttweld, Socketweld |

Application of Duplex/Twin Strainer

Basket strainers can only be put on parallel pipes, and the base of a larger, bulkier basket strainer must be made stronger.

The basket strainer’s cover can be removed so that the filtering part is easy to get to if it needs to be changed (due to stocked-up debris). When basket-style strainers are used on steam systems, they can collect a lot of condensates. So, steam strainers usually have a stopper for the drain and a steam trap to catch the droplets.

Back Nut Strainers

A back nut filter looks like a rear nut on its top half and is attached to the plumbing system at the bottom of the sink. Its nut is good for the draining system of a house sink because you can turn it.

Standard Size of Back Nut Strainers

| Bigger Size (inches) | 4.3×1.2×3.1 |

| Smaller (inches) | 3.4x1x2.3 |

For example, if strange things got stuck in the filter and stopped the water from going where it was supposed to go.

In this case, the stuck particles will fall out when the rear nut of the filter is turned.

Flange Strainers

The flange filter is one of the sink strainers that are the most expensive. It is one of the sink strainers with a lot of great features. It works as a filter, back nut, removal, and water stop. This makes it a sink strainer that does everything. Most flange filters are black with a matte finish.

It has a rubber ring under the cover to keep water out. To stop the water from flowing, push the nut into the drainage system so that it sticks. It has dimensions of 3x3x3, 4x4x4, or 5x5x5 inches.

Advantages of Flange Strainers

- Easy to put up and take down

- It can fit some sinks that have garbage disposal hooked up to them.

Double Cup Strainers

A strainer with two cups is something special. There are a lot of rubber and steel rings in it. It can be changed because it has two strong strainer cups and a rear nut filter. Most of the time, one cup is attached to the hole for the drain. The second one goes on top of the one that is linked. It can be taken off to clean.

The top cup is a wall, and the bottom holds things. It is usually built and made to keep the sink’s drainage system clean and debris-free. A two-cup filter will not let anything significant through.

Stainless steel & brass are used to make the most of this filter. It keeps rust from building up. It is 4x3x1 inches. Installing it is easy, and you won’t need a plumber’s help.

Advantages of Double Cup Strainers

- Very durable

- Stops debris from entering your pipe

- Calm to clean

- Can stop sewerage water flow

Level Strainers

You should get a level strainer if you want a standard sink strainer. The level strainer doesn’t use a specific machine system or any other rubber technology. It is 6x4x1 inches. It only has a big net to keep big and small things from falling into the sink.

The level strainer works with a circular plastic stopper that stops the water flow when needed… It seems to have a simple structure and no nut system. Some level filters have an extra rim that stops water. A level strainer is the best way to keep drains from getting clogged.

Advantages of Level Strainers

- Very Reasonable

- Easy to put up and take down

- It can stop any trash, no matter how big it is

Drain Strainer

Drain strainers work very well and can stop food waste and other solids from going down the drain. Drain strainers have a substantial metal screen or mesh that keeps things from going down the drain.

This filter is the most popular type because it is the easiest to use. Just put it on the drain, and it will easily filter food. But you should know that a drain strainer can’t stop water from going through. Like level filters, there is no way to permanently attach them to your drain, so they might float when your sink is full of water.

Stopper Strainer

The stopper strainer sounds precisely like a flash strainer with a built-in stop. Most stoppers have a screw in the middle that separates or connects them. It is 6.1x5x6.1 inches.

When the plug is in place, water can freely flow through the drain, and the strainer catches debris. When the sink is plugged in, the water stays there until the plug is pulled out.

Advantages of Stopper Strainer

- Very Reasonable

- Easy to put up and take down

Temporary Strainers

Temporary strainers are the best choice when money is tight because they cost less. Between the pipe and flanges are these strainers.

There are three types of temporary filters, each with a simple shape.

- Flat

- Conical

- Truncated

Most of the time, these filters are lower to the ground than basket strainers. The strainer tends to get messed up because so many things are going through at once.

Special Type Strainers

Several other particular types of filters on the market are also used for different things. The strainers are grouped based on their obvious features and the pipe systems. In some situations, you need to use a certain kind of filter.

- Magnetic Strainer

Magnetic filters work well to stop pump seals from wearing out too quickly. Magnets make a magnetic field, which draws iron molecules to it. Iron molecules cause pumps to rust, which causes them to break.

- Offset Strainers

Offset strainers work better on pumps close to the ground and require filters. The output of this strainer is low, but the intake is high. Even though the pump is close to the ground, there is less chance of contamination.

- Micronic Strainers

Micronic strainers use a very small mesh to eliminate particles as small as 5 microns. People use this kind of strainer to do things like separate water from fuel.

- Reducing Strainers

With reducing strainers, you don’t need reducers. You can reduce the pressure drop by cutting the pipeline size using these strainers.

Material of Construction

Cast iron is the most common material for strainer bodies because it is cheap. It is used in systems where the water pressure and temperature aren’t too high and where there aren’t a lot of thermal or mechanical shocks. Cast iron is mainly used for more extensive potable water lines and many systems that don’t use potable water.

Bronze: For use in brackish, salty, and seawater, bronze is the best choice. It is often used to get water that can be drunk.

Carbon steel is used in places with high temperatures and pressures and where the material needs to be resistant to thermal and mechanical shocks.

Chrome-moly steel: It is used when temperatures and pressures are high.

Stainless Steel: Often, stainless steel is used where erosion is a big problem.

Strainer Screens

Strainers are of two types:

- Perforated Screen

- Mesh Screen

Perforated Screen

The sheet is rolled into a tube and welded together in a few places. These screens usually have holes between 0.8 mm and 3.2 mm in Size. So, screens with holes can only be used to clean out general pipe debris.

Mesh Screen

A grid or mesh is made from small pieces of wire. It is usually put on top of a screen with holes, which acts as a cage for the mesh. You can make much smaller holes using a mesh screen instead of a perforated screen. It is possible to make holes as small as 0.07 mm. After that, they are used to get rid of tiny particles that would otherwise get through a screen with holes.

Key points for choosing proper Strainers

Flow Velocity

Flow speed and a pressure drop directly affect each other. The flow rate is likely to be slower if the material is thick.

Open Area Proportion

How long the strainer can work well before it needs to be cleaned is based on the ratio of open area to capacity. This factor also affects how much pressure loss there is inside the strainer.

Knowing how much the strainer is open is important because it shows when the mesh needs to be cleaned or replaced. When a strainer gets clogged, the pressure drops by a lot. When the Open area proportion is high, the media has a lot of particles or is very sticky.

Mesh Size

The Size of the mesh determines how much the strainer can filter. The smaller the mesh, the more force it can hold. Count how many holes there are in one inch to find the mesh size of a screen. On the other hand, a 10-mesh screen has ten holes over that one-inch line.

The plus sign shows that molecules with a diameter more significant than that number can’t get through the mesh. A number with a minus sign means only particles smaller than that number can get through. For example, a +400 mesh means molecules 37 microns wide can’t get through. Molecules with a diameter of fewer than 250 microns can get through a -60 mesh.

Link Between Strainer Kinds and Pipe Alignment

Pipes are only sometimes set up so that they are horizontal. Only when the flow is going downhill can the tubes be in a straight line.

On the other hand, the best strainers for vertical pipes are the Y-type or tee-type basket strainers. This makes it easy to catch the particles and ensures the trash doesn’t flow back upstream.

On the other hand, the strainer is placed as low as possible so debris can be flushed out easily.