Numerous individuals think that pressure relief and pressure safety valves are interchangeable. Although they exhibit similar appearances, they operate on a fundamental level. Safety valves prevent system operation until the pressure falls below the maximum operating level.

Without stopping the operation of the system, relief valves regulate pressure increases. If the system pressure exceeds the pressure limit set for these valves, the system will stop. This post discusses the pressure safety valve vs the relief valve.

What Does a Safety Valve Mean?

Safety valves are devices designed to prevent failure. It contains the pressure from rising above a certain level via automatic operation. They are in boilers, power services, petrochemical, and water heater systems. When the pressure reaches a certain point, the PSV will stay open until the pressure goes back down.

The media pressure exceeds the pressure of the pressure safety valve. After this, the media comes into contact with the complete closing mechanism. It consists of a poppet or disc.

It increases the surface area against which the media circulates. So this raises the pressure applied to the closing mechanism and causes it to open quickly.

Different Types Of Safety Valves

Typically, there are three types of pressure safety valves. These are bellow pressure safety valve, direct acting PSV, and pilot operated safety valve.

Bellows:

Using the bellows above the poppet, the bellows PSV diffuses and decreases back pressure. Backpressure is a pressure build-up at the valve’s outlet, which may flow back into the valve.

Direct-acting:

A spring supports the closing mechanism of a direct-acting pressure safety valve. The adjustable or non-adjustable spring regulates the pressure setpoint.

Pilot operated:

The pilot controls the pressure setpoint of the pilot-operated pressure safety valve. This type of pressure safety valve enables a response pressure closer to the system’s working pressure.

What Is A Relief Valve?

In proportion to the control system pressure, a pressure relief valve regulates the system pressure. It secures devices sensitive to pressure against the negative impacts of overpressure.

A relief valve begins to work before the system’s pressure becomes unsafe. Pressure increases are slowed. When the pressure from the system reaches the setpoint of the relief valve, the valve becomes completely open. It halts the build-up of extra pressure within the system. Various applications contain standard pressure relief valves.

Types of PRVs

These are different types of pressure relief valves: balanced pilot-operated, electrical, direct-acting, and remote-controlled.

Direct-acting:

The direct-acting relief valve reduces system pressure. It possesses a solitary spring-supported pop that operates to a direct-acting safety valve. You can either adjust the spring, or it cannot be adjustable.

Electric:

An electric PRV system uses solenoid valves to permit or restrict flow between relief valves. This setup enables quick changes to the system’s pressure setpoint.

Pilot-operated safety valve:

A pilot-operated pressure safety valve and a pilot-operated RV are similar in design. The pressure setpoint shows less difference when comparing the direct-acting relief valve to the cracking pressure.

Remote-controlled:

A direct-acting pressure relief valve manages a remote-controlled relief valve’s adjustable pressure setpoint. Connecting the two valves via a narrow conduit acquires it. Now, let’s understand the difference between pressure relief and safety valves.

Difference Between PSVs and Relief Valve

Before buying the safety and PRV from a reliable valve supplier or wholesaler, you must understand the differences between these valves. Here are the main PSV and PRV differences: function, design, operation, and setpoint.

1. Designing for Safety Relief Valve Versus Pressure Relief Valve

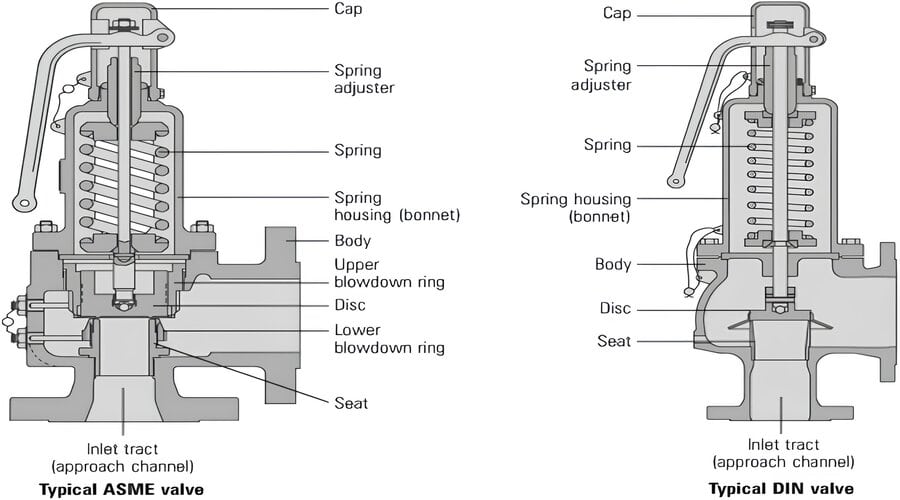

The designs of essential safety valves and relief valves are identical. A seat-mounted disc supported by springs maintains the valve’s closure. It is held until the system pressure reaches the valve’s designated pressure. You can fix the spring in place or adjust it to alter the valve’s set pressure.

The disc is the primary design element that gives rise to the operational variations. A small round object on a valve remains in place. It stays there until the pressure becomes strong enough to push it up. This pressure must overcome the resistance of the spring.

When you close the valve, the pressure cannot interact with the rim of a safety valve. When the safety valve ruptures, the pressure exposes the lip.

As the pressure interacts with a greater surface area, the disc experiences an increase in force. This initial expansion causes the disc to become approximately 60% completely ajar. As pressure rises, the disc expands until it is entirely open.

2. Operation of Relief Valve Vs Safety Valve

The operational difference between a pressure safety valve and a pressure relief valve is misinformation. Industrial settings often use two distinct varieties of valves: safety valves and relief valves. Although both valves perform vital functions, they function in different ways.

The pressure relief valve opening is proportional to the increase in pressure beyond the setpoint. Gradually, the orifice closes. Safety valves will open immediately after the system pressure reaches the predetermined threshold.

3. Setpoint Of Pressure Safety Valve Vs. Pressure Relief Valve

Another difference between a pressure relief valve and a safety valve is setpoint. The PRV starts the opening process at the precise pressure called the “setpoint.”

Assigning pressure to setpoints is not the correct interpretation. We configure the setpoint of a pressure relief valve to the minimum pressure rating attainable. It indicates the lowest system pressure at which we can detect an overpressure.

When the pressure surpasses the setpoint, the valve will start the process of opening. The setting point is set in pounds per square inch (PSIG) and must stay within the most allowable operating pressure (MAWP) limits. The standard setpoint for pressure safety valves is approximately 3%. Above the working pressure, the setpoint for relief valves is 10%.

4. Function Of Pressure Relief Valve Vs Safety Valve

A pressure relief valve protects a component or system against excessive pressure. In contrast, the function of a PSV is to prevent damage from over-pressurization. Various industries utilize both varieties of valves. However, each has distinct advantages and disadvantages.

Typically, systems use PRV when even minimal over-pressure can result in adverse effects. On the other hand, systems that could have bad effects from over-pressurization need safety valves. Selecting the appropriate valve type for a given application is critical, as both have benefits and drawbacks.

Relief valves close once the pressure reduces below the opening pressure. Safety valves function similarly, securing the apparatus against excessive pressure build-up. However, someone needs to close safety valves to keep them open manually. It is installed when a closed valve is unsafe, such as in a gas or liquid line.

For more details about PRVs, click here.

Can We Use Pressure Safety Valves and Relief Valves Interchangeably?

No, the pressure safety and relief valve are not interchangeable. Both types of valves are seal butterfly valves. These serve safety purposes, and they have distinct functions. A relief valve regulates the pressure within a system. However, a safety valve releases excess accumulated pressure.

Distinguishing between these two varieties of valves is vital. Using the incorrect valve for its intended function could result in serious issues. Always seek professional help when unsure about which form of valve to use.

Safety Valve Vs Relief Valve: Bottom-Line

A few essential distinctions distinguish a safety valve from a pressure relief valve. Relief valves are intended to release pressure from a system when it becomes too low. The safety valves are designed to reduce pressure when it becomes too high.

Safety valves are designed to open at a designated pressure, whereas relief valves are designed to open at a specified vacuum level. PRV can be utilized repeatedly.

However, safety valves are designed for single use only. Select a reliable valve manufacturer that aligns with your unique business requirements.