Choosing an experienced supplier is crucial. Ball valve suppliers who have been around for a while have shown they can handle industry ups and downs and always provide what their customers need.

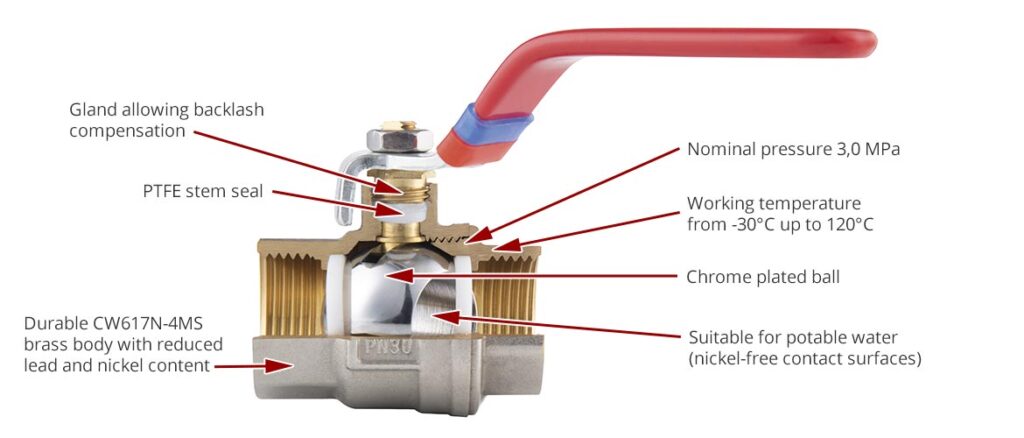

Treatment of Material:The way in which raw materials, such as brass, stainless steel, or any other metal, are handled may have an impact on their performance, in addition to the sourcing process. Processes like alloying or even unique treatments may be used to increase the lifetime and durability of materials.

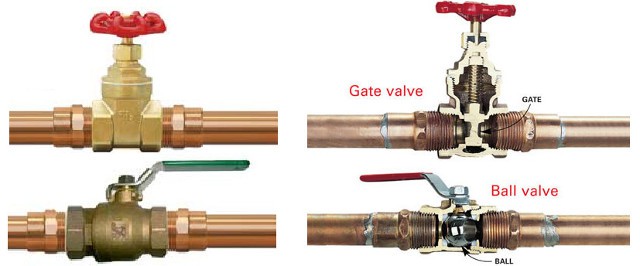

Standards and Product Quality:We will not compromise on quality. Ensure the ball valve supplier’s products are certified and up to industry requirements. Quality assurance procedures and material selection influence valve performance

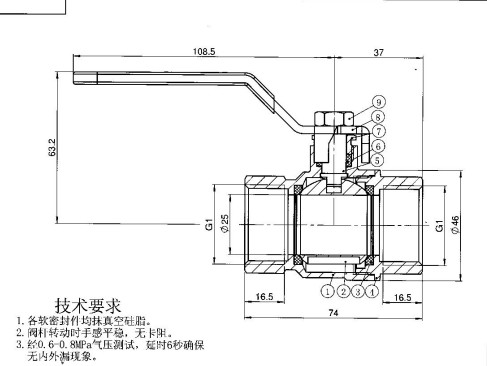

Technical Support and Customization:Solutions tailored to your specific operating demands may be necessary. To ensure the valves fit your needs, look for a source offering technical assistance and customization options.

Exploring Potential Wholesalers:

Look online first and Inspect the supplier’s website, read reviews, and check ratings. You may learn a lot about a supplier’s strengths and shortcomings from customer interactions.Communicate and inquire with prospective vendors face-to-face. Get to know their offerings, services, and personalization choices. Customer happiness is their priority, so they communicate quickly and clearly.

Learning About Price Structures: Evaluate price quotations from various vendors. Prices that look too low should raise red flags. Get a feel for the price system, and make sure you ask about any hidden fees.

Assessing Supplementary Service Options: Think about adding value with services like maintenance, technical support, and post-purchase help. These services improve things in the long run and improve the whole thing.

Fame on a Global Scale: It’s not enough to have qualifications; these certifications must be recognized globally. Marks such as ISO, ANSI, or C.E. are trusted by people worldwide and are easily recognizable. Certifications emphasizing safety standards are particularly important for valves intended for critical applications. Inspect their commitment to safety by looking at their safety milestones, any violations, and the steps they take to fix them.

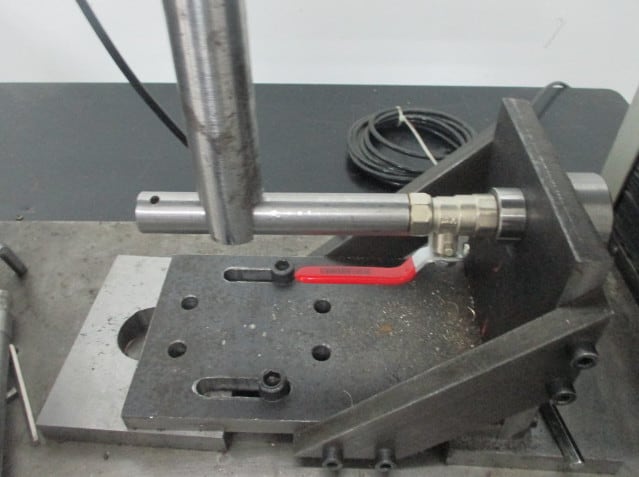

Understand what the ball valve supplier’s testing protocols are. We guarantee the valves’ dependability under diverse situations by thoroughly testing them, including pressure and leakage tests. To keep projects on schedule, logistics, and timely delivery are of the utmost importance. For on-time order delivery, inquire about the supplier’s shipping and delivery procedures.

Research and development priorities: Technological If a provider spent a lot of money into R&D, they want to be the first to market with new technologies.