What is bronze?

Before moving to our main topic, bronze ball valve vs. bronze gate valve, understand the term “bronze.” Bronze is not a pure metal. It is an alloy of tin and copper. However, lead, aluminum, nickel, or zinc are added to gain qualities and performances suitable for various industrial uses. Moreover, it is a solid and malleable material that does not crack quickly.

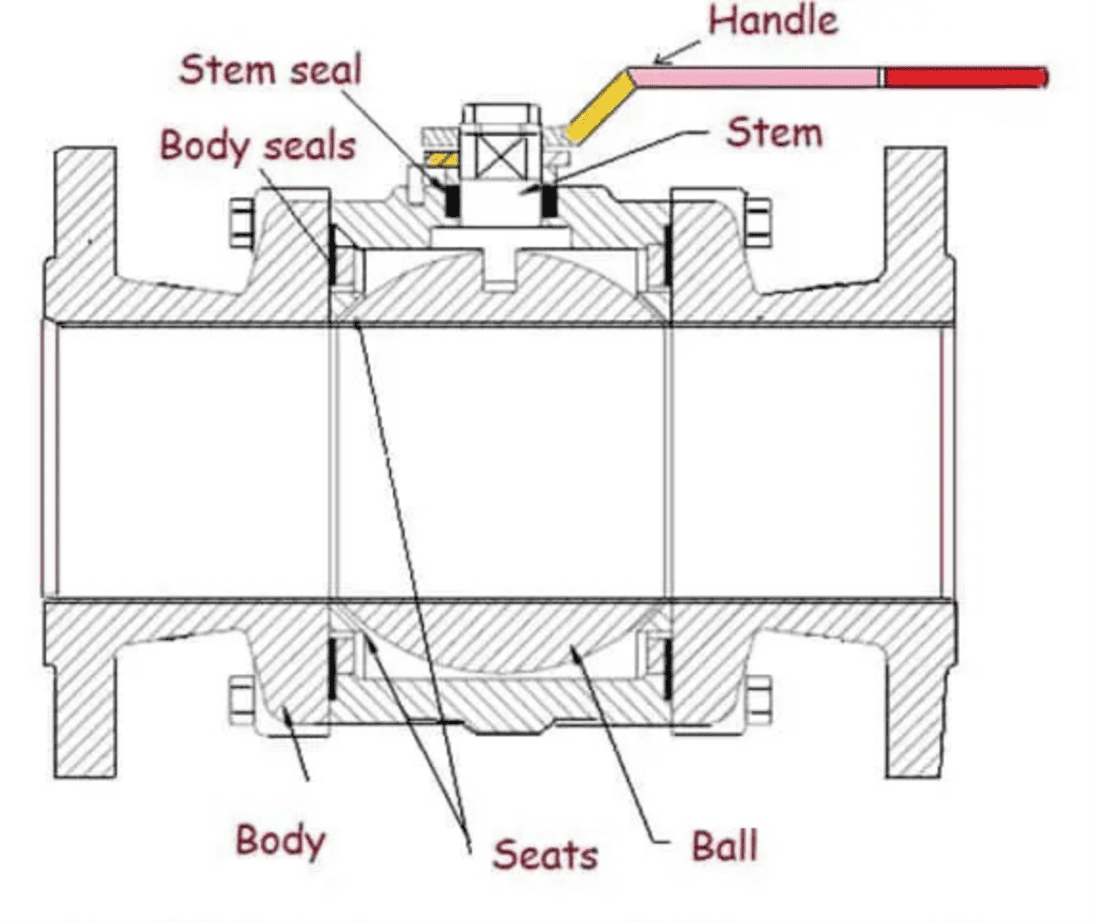

What is a bronze ball valve?

The bronze ball valve controls flow direction, shut-off, and safety relief valves. When the hole is in line with the flow direction, fluids or gases can pass through. In contrast, when the ball is rotated 90 degrees, the flow is stopped. In both cases, the handle acts as a visual indicator of the condition of the valve. The valve is open if the handle is parallel to the valve. When the handle is perpendicular to the valve, the valve is closed.

Benefits of bronze ball valves

There are numerous advantages to using bronze ball valves in your processes. Not only are they durable, but they are also suitable for high-performance applications. Among other advantages, bronzes are resistant to corrosion. This material can withstand extreme heat, pressure, and various situations. In addition to being highly malleable and ductile, it is an excellent material for valves. Additionally, copper’s outstanding antimicrobial characteristic makes it perfect for water and chemical systems. If you want to acquire

Bronze Gate Valve

The PN20 pressure rating makes it appropriate for oil, water, steam, inert gas, and air use. The maximum operating temperature for bronze gate valves ranges from -20 to 180⁰C. It also has an integral seat free of asbestos. ASME, BS, EN, ASTM, and other industry specifications make the bronze gate valves.

Bronze gate valve features

- It can be used to make relatively small gate valves for low-pressure purposes.

- Simple to operate with, strong, and resistant to corrosion

- More expensive than PVC but less costly than stainless steel and brass

- Bronze is more corrosion-resistant than cast iron but less resistant than PVC or brass. It costs more than PVC but less than brass or stainless steel.

- Most of the time, bronze gate valves are used on water pipes and equipment pipelines with pressures of less than 300 psi (20 bar) and temperatures between -20° C and 150°

Bronze gate valve applications

Bronze has a good amount of lead, so it’s rarely used for drinking water applications. Bronze is often used in low-pressure manufacturing to control the flow of fluids. It works well with air, steam, and gas. The material is also used in marine and HVAC systems.

Bronze Ball Valve Vs. Bronze Gate Valve

Selection standards

Before deciding between a bronze ball valve and a bronze gate valve: A gate valve has two ports, whereas a ball valve may have more than two.

Flow Capacity:

Since bronze gate valves often have bigger diameters than bronze ball valves, they can give greater flow capacity. Opening and shutting speed: Due to its quarter-turn on/off function, a ball valve is better suited to applications requiring rapid opening and closing speed or during emergencies. A bronze gate valve takes more significant than 360° rotations to operate, making it slower than a ball valve.

Pressure:

Both ball and gate valves are suited for applications with low pressure. However, a gate valve is preferable for applications involving high pressure. This is due to the rapid opening and closing of the ball valve, which might result in a water hammer.

Cost:

Generally, a ball valve is more expensive than a gate valve with the same specs. In contrast, ball valves are often more resilient and require less care than gate valves. Therefore, a ball valve may be more cost-effective over time.

Bronze Gate Valve vs. Bronze Ball Valve: Working Mechanism

The working mechanism of a bronze ball valve

The media flow is controlled by a ball valve hollow sphere in the center. You can understand how the ball valve works by rotating the shaft or stem by a quarter of a turn. The stem of the valve will be perpendicular to the ball.

Fluid can flow through when the stem is appropriately angled concerning the ball disc. The media’s ability to flow laterally is critical to the shut-off process. When a ball valve is configured correctly, fluid pressure acts on the valve or the seat to build a seal.

Ball valves come in two varieties: full port and reduced port. When a ball valve is “full port,” its diameter equals that of the pipe installed. As a result, the working torque and pressure drop are kept to a minimum. But there’s also a reduced port type, where the valve’s port is smaller than the pipe’s.

TECH2SECRET

The working mechanism of a bronze gate valve

The gate or disc must be raised for media to flow through a gate valve. These valves restrict flow in one direction and negatively impact pressure. Handwheels were commonplace on gate valves. The packaging is attached with a handwheel.

The stems of gate valves might be of two distinct types. Rotating this hand wheel raises the stem into the environment and opens the gate. Another type of gate valve is the non-rising gate valve. The stem is threaded into the wedge, revealing its side to expose it to the media.

By releasing its seal, the gate valve expands the passageway. The media can fill the space along the flow path, making it anything but linear. The flow rate would be irregular if the gate valve was employed as a throttle. There will be vibrations as a result of this. The vibration damaged the disk.

Bronze Gate Valve vs. Bronze Ball Valve: Valve Design and Construction

Gate and ball valves have similar purposes, but their structures are distinct.

Ball valves allow for unrestricted flow of the medium they are used with. Also, the ball valve design permits it to keep working even after heavy use. Of course, one must also consider the material from which it is made.

Despite their absence of fine control, ball valves have one of the best tight-shut abilities for use in low-pressure settings. In this respect, ball valves have a proven track record of durability. Low-pressure drops characterize ball valves. Ball valves are more compact than those with a quarter-turn capability but still require more room.

However, a gate valve’s disc can be opened and closed with the turn of a handwheel. Because the valve body is so much thinner, a small area is required for it to do its work. In contrast to ball valves, gate valves provide precise control due to their throttling abilities. Regardless of the absence of instant on/off capabilities, it enables accurate regulation of both media flow and pressure.

Bronze Gate Valve vs. Bronze Ball Valve: Durability of Valves’ Seals

Bronze ball valves can have either floating or fixed seals, depending on whether they are trunnion-mounted or floating. Due to their working mechanism, ball valves are typically utilized in low-pressure applications. Hence, PTFE and similar materials are generally used for the primary seals.

The bronze ball valve’s ability to open and close rapidly has its uses but can also be problematic. As the valve is closed, a water hammer, or an abrupt increase in pressure, can occur in systems fitted with ball valves. Because of this problem, the ball valve seats erode.

The internal pressure of a bronze ball valve can also rise due to a water hammer. An emergency seat seal, typically constructed from metal, is installed when such a scenario arises, such as when working with explosive materials. This is the second barrier if the elastomeric seal is compromised in high-pressure services. Ball valves can have a pressure vent added to release pressure.

When fully opened, the pressure loss caused by a gate valve is minimal. This is possible due to the usage of full bore port configuration. If the pipe is the same diameter as the valve, then the two are compatible. Because of this quality, gate valves are preferable to ball valves. Gate valves are resistant to water hammers because of their design.

One potential problem with gate valves is the high-pressure differential during the shut-off. Wear on the seat and disk could result from friction.

Bronze Ball Valve Vs. Bronze Gate Valve: Size

Bronze Ball Valve Size (Screwed Ends)

| Size (mm) | Size (Inches) |

| 15 | ½ |

| 20 | ¾ |

| 25 | 1 |

| 32 | 1.1/4 |

| 40 | 1.1/2 |

| 50 | 2 |

| 65 | 2.1/2 |

| 80 | 3 |

| 100 | 4 |

Bronze Gate Valve Size

| Size (mm) | Size (Inches) |

| 8 | ¼ |

| 10 | 3/8 |

| 15 | ½ |

| 20 | ¾ |

| 25 | 1 |

| 32 | 1 ¼ |

| 40 | 1 ½ |

| 50 | 2 |

| 65 | 2 ½ |

| 80 | 3 |

Bronze Ball Valve Vs. Bronze Gate Valve: Maintenance

Bronze Ball valve maintenance

Bronze ball valves should be subjected to preventive or predictive maintenance ahead of their failure. To extend the life of valves, incorporate the following measures into the maintenance and management system of the site.

Correct installation

Bronze ball valves placed correctly have a significantly lower chance of requiring replacement or repairs. Ensure that the engineer installing the ball valves has the necessary knowledge and experience.

Regular cleanings

Clean valves have a longer lifespan since there is less possibility for debris to accumulate and hinder the operation of the pipe system. Use cleaning products that will react well with the materials of the valve. For metal components, gas-based or compressed air cleaners work well. Still, alcohol- or water-based cleaners are appropriate for non-metal parts. At least once a year, and more mainly if the manufacturer’s environment contains dirt and dust, ball valves should be cleaned.

Lubrication of valves

Lubrication maintains the smooth operation of ball valves, avoids abrasion, and enhances the efficiency of valve seals. Adhere to synthetic, water-insoluble, oil-based lubricants; avoid clay- or solid-based lubricants that can accumulate within the valve cavity. Choose a lubricant that is suitable for the materials of the valve and the system media.

Routine inspections

Have valves routinely inspected by a qualified inspector? Ball valves in high-pressure and high-cycle applications should be inspected more frequently than annually.

Maintenance and Inspection of Bronze Gate Valves

1) Regular monitoring of the valve is required.

2) If a stem packing leak develops on a valve, adjust the packing nut to improve pressure on the stem packing. The packing nut should be twisted roughly ¼ to ½ turn clockwise.

3) If tightening the packing nut does not stop the leak, the backseat can be utilized to reduce the leakage until conditions allow for a system shutdown and packing replacement.

4) Changing stem packing with the valve under pressure and in the back seated position is dangerous. The risk increases when fluid pressure or temperature increases or when the fluid is poisonous.

Installation of Bronze Gate Valve

1) The standard gate valve can be placed for flow in either direction.

2) Ensure that the piping system has been carefully cleaned and prepared before valve placement and that the pipe threads are free of excessive grit, dirt, or burrs.

3) Use pipe sealant, which is suggested for valve end use, on threaded valves.

4) Use solder on solder joint valves, as suggested for end-use valves.

5) Inspect the valve ports and seating surfaces for cleanliness before installation. Care should be taken to ensure that pipe sealant is not applied excessively to the pipe threads to clog the valve seats.

6) Provide support for the valve to prevent strains caused by the connected pipe.

7) Move the valve from its fully open position to its closed position.

8) After installation, verify the tightness of the packing nut.

Is a Bronze Ball Valve better than a Bronze Gate Valve?

Bronze ball valves and bronze gate valves are both meant to control flow. They each have unique applications, except for slightly different purposes. A bronze ball valve is a stem-operated valve in which a ball rotates in a horizontal position. This valve, also known as a “rotational valve,” is typically employed in situations where pressure drop is not a significant factor. On the other hand, a gate has a flat sealing surface between the seat and the gate and can only be opened or closed.

The flow of fluid into or out of the system is the only thing the valve controls. Hence it is typically utilized in situations where there is no pressure drop. Valves of this sort are superior because they have a one hundred percent shut-off rate. They are easier to install and require less upkeep than gate valves.

Bronze ball valves offer several benefits over other valve types. Their compact design suits them more to high-pressure environments and tight quarters. Yet, ball valves have a lower failure rate and longer lifespan. A ball valve is preferable over a gate valve because of its longevity, adaptability, and simplicity.