Angle valves and gate valves. Valves that you will find at valve wholesalers. This is where the similarities end. There are many differences between these two valves that are important to know. The size, material, function, and prices are different.

What is an angle valve?

An angle valve has many different names. It is known as an angle stop valve, shut-off angle valve, or corner valve. This fitting is in an “L” shape at a “9”-degree angle; this is the main reason for its name. On the one side, there is an inlet, and on the other side an outlet. You will find these valves at a corner in water pipes and gas pipes. There are different types of angle valves that you can buy at a valve distributor. You can find these fittings in different sizes:

- ½ x 3/8

- ½ x ½

- ½ x ¾

There are different types of angle valves to choose from. It’s important to know as much as possible about these different angle valves that can be purchased from a valve distributor.

- Multi-turn angle valves.

- Compression angle valves

- Angle ball valve

- 2 in 1 angle valve and 3-way angle valve

- Angle stop check valve

What is a gate valve?

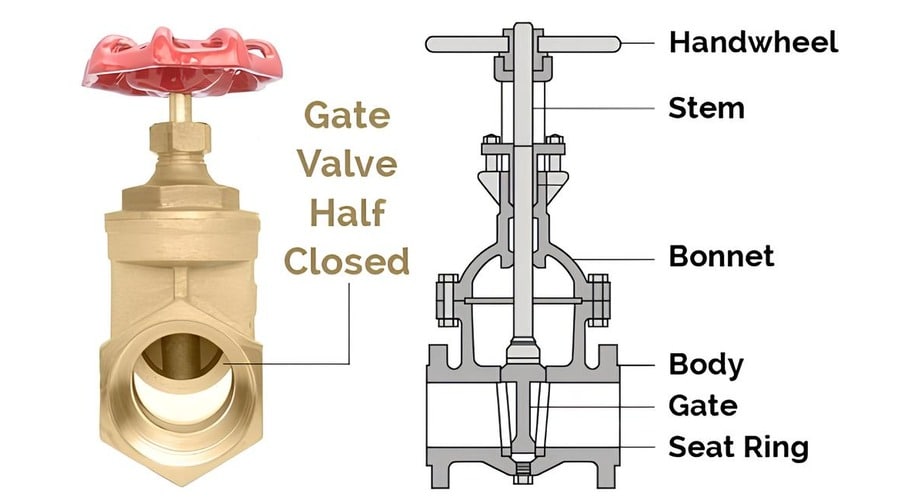

Even if there are some similarities between an angle valve and a gate valve, there are also some differences. The gate valve is to shut off fluid flow completely or to provide full flow in the system. This can be for anything from oil, gas, or even water.

Gate valves are linear, unlike the angle valves. It can only shut the flow completely or open the flow fully. No precise control is possible. You can find the fitting at any Brass gate valve manufacturer. What makes this fitting different is the versatility and other options available.

The function of the gate valve is similar to that of the angle valve. The main reason why people confuse these two fittings is that the fitting has two sealing surfaces. This is the opening and closing disk. It works manually and can shut down a system. However, it can be used in more ways than other valves.

The main differences between gate and angle valves

The main differences between angle and gate valves, according to valve wholesalers, are:

Should you choose the brass angle valve or the gate valve? Because of its similarities, deciding which fit to use can be difficult. According to copper fitting suppliers, there are some differences between these two fittings that you need to know about. To make the decision on which fittings to use easier.

- The angle valve has a disc that is rotating to block fluid flow. The gate valve has a ridge or wedge that slides into place.

- It would be best to use the gate fitting for thicker or viscous fluids, while you can use it for thinner liquids and gas with the angle fitting.

- Angle valves should be replaced more than gless expensive gate valves

- The weight and durability of the gate valve are better than the angle valve.

- Gate valves are typically used in larger pipes, while angle valves are best used in smaller pipes.

| Gate valve | Angle valve | |

| Application | Wedges that slide into place, household, commercial, industrial, Plumbing | Disk that rotates, toilet, washbasin, kitchen, heating system |

| Use | Thicker or viscous fluids | Thinner liquids and gas |

| Size | 1/2 “-4” | 1/4 “,3/8” “1/”” |

| Price | $0.8-$60 as the normal | $0.5-3.5 as usual |

| Lifespan | Five-year warranty with brass raw materials | 300000 times on-off |

Explaining the differences between gate and angle valves

There are some differences between the gate valve and the angle valve:

How the valves work

A gate valve has a ridge, also known as a wedge, that slides into place to open and close the valve—one of the reasons why a gate valve can be used for thicker and viscous fluids. An angle valve makes use of a disk that is rotating to open and close the flow. It is best to use for thinner liquids or gas.

When it comes to clogging

The gate valves are of higher quality and are less likely to clog. Angle valves are more miniature, ideal for light-duty work, and are considered a high clogging valve.

The design differences between gate and angle valves

The design between a gate and an angle valve is completely different. The gate valve is linear, while the angle valve has a 90-degree angle. Gate valves come with sliding plates that slide to open and close. It is known that the gate is wedge-shaped.

The valve is designed with discs that rotate to open and close the valve. With the 90-degree angle, there is a small difference in flow restrictions because of the bend. There are different types of angle valves to choose from. More than with the gate valves.

The material differences between gate and angle valves

A gate valve is made from cast iron, ductile iron, gunmetal, stainless steel, and alloy steel. Angle valves are made from Nickel-bronze, brass, bronze, stainless steel, or high-grade plastic. The only similarity between the gate and angle valve material is stainless steel.

For angle valves, it is essential to choose corrosion-resistant materials. Gate valves are made from rust-free materials that are strong and long-lasting. It is due to the type of fluids that run through them.

Valve replacement timeline

Angle valves need regular maintenance and replacements. This is due to the angle of the pipes. It can cause clogging and can lead to failure. With a gate valve, it is more robust and longer lasting. It replaces the valve as regularly as the angle valve isn’t necessary.

There are many differences between gate valves and angle valves. The most crucial difference is that angle valves are made with an angle, while the gate valve is linear. The gate and angle valves can be found at a valve distributor.