Description

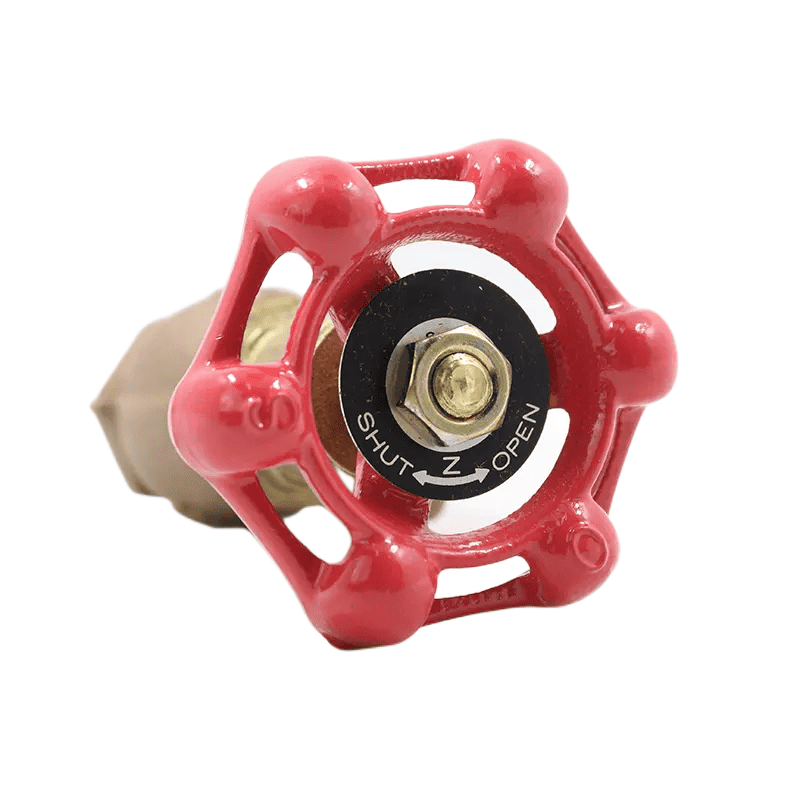

150 cast bronze Globe Angle valve

JX-0216

Globe Angle Valves, 2-way customized

The temperature of Media: Low Temperature

Port Size: DN8-DN80

Structure: Control Product

Medium: Water gas oil body

Standard: ANSI BS DIN JIS

Size: DN8-DN80

Connection: NPT

Working pressure: PN16

Working Temperature:-10℃~120℃

Angle Globe Valve Specs

| Water | Air | |

| Shell | 2.40*(1/4-2inch,8-50mm), 2.10(21/2-3inch,65-80mm) |

0.6(1/4-3inch,8-80mm) |

| Seat | – | 0.6(1/4-3inch,8-80mm) |

| Back Seat | – | – |

The bronze angle globe valve is a straight globe valve with the ends cut off at a 90° angle. It generates low-pressure drops due to its design to sustain fluid passage in conduits at an angle of 90°. It is optimal for regulating various fluid categories. When appliances necessitate pulsating flow due to their exceptional manipulating impact capability, angle-type globe valves are the optimal selection.

The robust construction of the angle globe valve incorporates premium metals such as brass, bronze, and stainless steel, ensuring its malleability and corrosion resistance. Temperature between 250°C and 450°C is typically necessary for cryogenic applications. The angle globe valve is specifically engineered to be mounted securely using an angle seat.

What Is Bronze Angle Globe Valve?

A modification to a Z-body globe valve, an angle-type globe valve allows its diaphragm (the fundamental glove) to rotate at right angles to its pipe axis. This allows for more efficient operation and reduces the requirement to one elbow rather than two.

The fluid passage through the valve is adjusted by raising or lowering a disk or particles that comprise the valve’s globe-shaped body. The angle between the inlet and exhaust openings changes fluid flow direction, which aids in mitigating turbulence and pressure reduction.

Why Do You Need Bronze Angle Globe Valve?

The angle globe valve’s disc, stem, and seat ring configurations are identical to those of the globe valves. With the elbow that these valves will substitute, flow resistance is reduced compared to standard globe valves. Moreover, it results in a reduction of connections within a line, consequently facilitating the installation process. Acquiring an angle globe valve is warranted due to the efficacy of fluid regulation.

How Does Angle Globe Valve Work?

Angle-type globe valves control the flow of gases or fluids through a pipe by opening and closing a port with a disc or plug that can be moved. The angular construction of these valves’ bodies enables their installation in confined spaces. The valve’s stem is connected to the disc, which can be opened or closed by turning the handwheel or actuator. Fluid or gas enters through the inlet port when the valve is opened, causing the disc to be displaced from the perch. The disc advances toward the seat as the valve closes, obstructing the flow.

Bronze Angle Globe Valve Uses

The versatility of angle globe valves results in their applicability in many contexts. Among the most prevalent applications for angle globe valves are the following:

- Regulation of air and water flow in HVAC systems

- Control of gas and hydrocarbon flow in pipelines

- Equipment isolation in chemical facilities

Advantages and Features of Bronze Angle Type Globe Valve

Globe valves of the angled variety control fluid passage within pipelines. Their benefits include straightforward assembly, efficient sealing, exceptional performance, and appealing aesthetics.

This valve is available in various disk configurations, including ball disk, composition disk, and plug disk. Ball designs are predominantly utilized in applications characterized by moderate pressure and temperature.

Simple construction

Angle globe valves provide many features and benefits that are difficult to surpass. They are an indispensably effective product, and their straightforward construction, efficient sealing, high-performance capabilities, and attractive appearance render them so.

This particular valve category finds applicability in various contexts, encompassing fuel oil systems, cooling water systems, and lubricant, chemical, and air systems. It is frequently selected due to its resistance to various temperatures and pressures.

Excellent performance

Globe valves of the angled variety have numerous advantages and benefits. They are practical, user-friendly, and resistant to leaking under various pressure conditions.

By eradicating pipe elbows and reducing flow resistance, angle pattern designs permit media flow to complete a 90-degree turn without requiring an elbow or additional welds.

Good appearance

Angle-Type Globe Valves have an attractive appearance. They are adaptable to various conduit diameters and provide a separate pressure class.

An essential benefit of angle valves is their ability to control fluctuating flow conditions caused by slugging efficiently. This attribute renders angle valves an indispensable alternative, as they avert conduit complications that can occur with alternative valves.

Effective sealing

Effective closure is one characteristic of angle-type globe valves, which are multipurpose valves with numerous applications and advantages.

To close or deactivate the valve, a stopper is threaded through the center of the valve’s spherical body, which is additionally equipped with an internal baffle.

Essential Points in Selection Parameters of Bronze Angle Globe Valve

The following additional parameters must be established if the valves are to be utilized for control purposes:

– procedures of functioning,

The maximal and minimum rates of flux,

The maximum and minimum pressure at the inlets of the valve, as well as the pressure decrease during regular flow and closing, are shown.

In addition to the fundamentals above, have a comprehensive understanding of the internal structures of various valves to select them rationally and accurately, thereby enabling the selection of the most desirable valves.

The final control element in pipelines is the valves. The valve’s operation governs the direction of medium passage within the pipelines.

The configuration of a valve’s flow channels determines its flow characteristics. This factor must be considered when selecting the most appropriate valves for the conduit system.

Angle Globe Valve Size Range

| inch | ¼ | 3/8 | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 |

| mm | 8 | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 |

| L | 44 | 44 | 53 | 65 | 77 | 85 | 100 | 119 | 139 | 158 |

| H | 66 | 68 | 79 | 93 | 104 | 127 | 145 | 174 | 199 | 215 |

| D | 50 | 50 | 60 | 70 | 80 | 90 | 100 | 115 | 135 | 155 |