The Leader Manufacturer of Cast Iron Valve

High-grade cast iron valves redefine robustness for demanding pipeline applications. These cast iron and ductile iron ball valves are designed for adequate fluid, gas, and oil management systems, offering unparalleled corrosion resistance and durability. Bespoke or OEM are both available. Manufacturing reliable valves to match your demands is our aim.

Plumberstar Manufacturing Cast Ductile Iron Valve

As a trailblazer in water solution parts factory since 2006, Plumberstar is dedicated to excellence and innovation. Our China-based manufacturing hub, backed by two decades of industry expertise, crafts a diverse range of water solution parts from durable materials such as stainless steel, polymers, and brass,cast iron and ductile iron. We pride ourselves on offering custom solutions that fit our clients’ water plumbing,gas and heating system unique needs.

Need To Know About Cast Iron Ball Valve

Cast iron, also known as gray iron, is a metal that has been used for a very long time. A mix of 96% to 98% iron, 2% to 4% carbon, and small amounts of silicone makes it up. Some types of cast iron can handle temperatures over 2100F (1150C), which is a very high temperature. The cast iron’s pressure class reveals how strong it is under pressure. A remarkable aspect of cast iron is that it’s not too expensive. Cast iron is usually the least expensive metal, making it a good choice for people tight on cash.

General Applications of Cast Iron Valve

Distribution systems, treatment facilities, and conduits are all aspects of the water and wastewater sector where cast iron valves are widely employed. They perform an essential function in regulating water flow, managing pressure, and preventing backflow. The cast iron valves most frequently utilized in this industry are check, butterfly, and gate valves.Valves of cast iron are utilized extensively in the oil and gas industry. Offshore platforms, pipelines, refineries, and storage terminals all employ them. These valves can effectively manage corrosive substances and high-pressure, high-temperature environments typical in this industry. Ball valves, globe, and gate valves, are examples of cast iron valves that permit precise regulation of the movement of gas and oil.

The valves are essential components in HVAC systems because they regulate the passage of hot water, steam, and chilled water. They ensure the efficient distribution of heating or cooling to various building areas. Globe and ball valves made of cast iron are frequently utilized in HVAC applications owing to their sturdiness, longevity, and capacity to withstand elevated temperatures.

Cast iron valves are indispensable for manufacturing assembly lines, chemical plants, industrial processes, and power generation facilities. The fluids these valves can manage consist of corrosive compounds, abrasive media, and high-temperature substances. They offer reliable regulation and ensure manufacturing procedures’ secure and effective functioning.

It critical components of fire protection systems as they guarantee the accurate distribution and passage of water in case of a fire emergency. Buildings use dry and wet riser systems to regulate water flow for fire suppression. Fire protection systems frequently utilize cast iron gate valves due to their resilient construction and capacity to withstand elevated pressures.

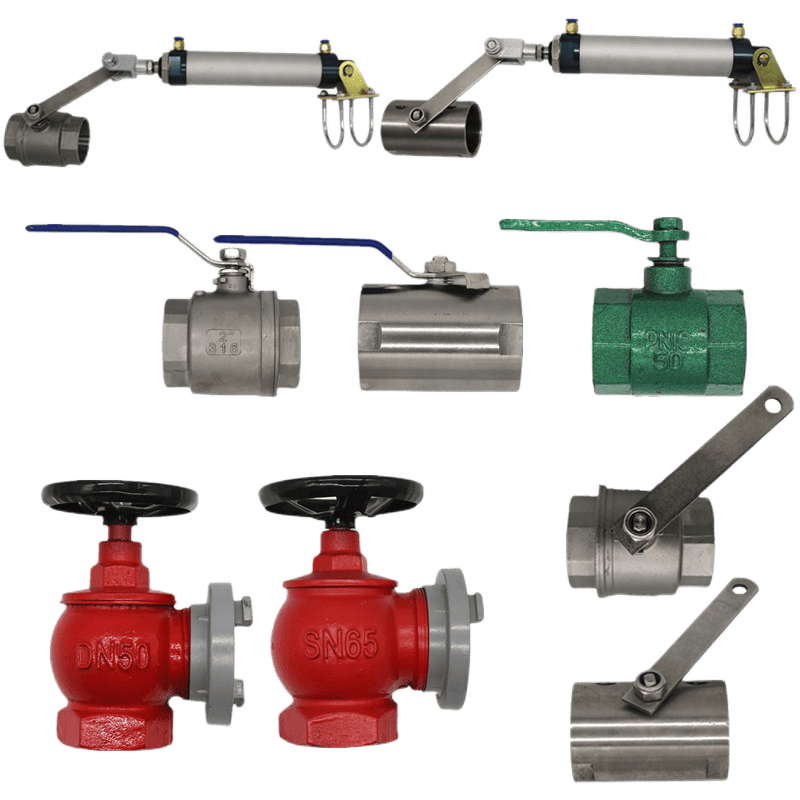

Manufacturing Types of Cast Iron Valves

Valves made of cast iron are a material alternative that is often used in a wide range of applications. This is because this metal has several distinctive properties. When choosing a valve, it is necessary to consider all of the properties of the material under consideration, such as its cost, strength, and ability to resist corrosion. The aim is to find a valve material capable of performing successfully without incurring extra costs for strength or corrosion resistance that are not considered to be essential. The majority of cast iron is made up of iron, with a tiny amount of carbon and a minor amount of silicone also present.

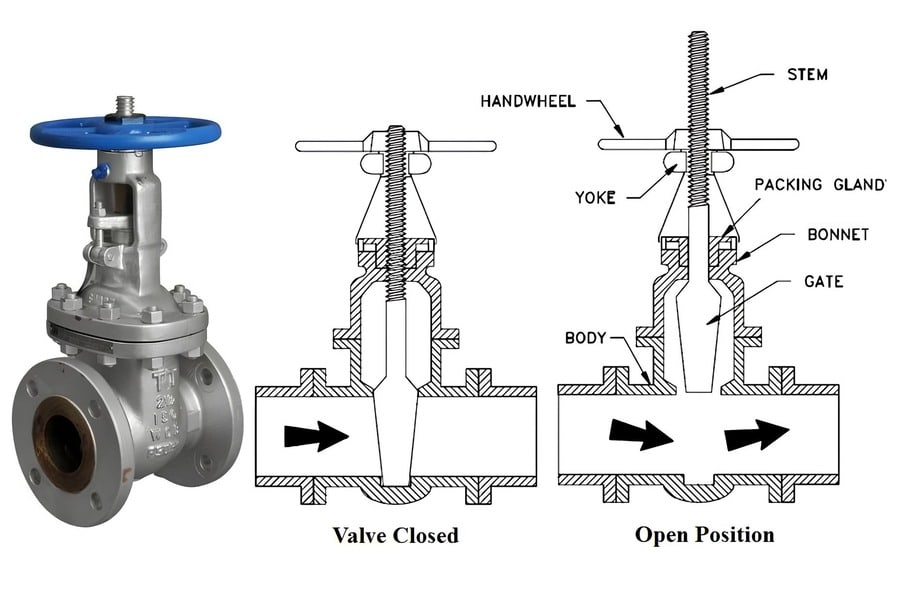

Cast Ductile Iron Gate Valve

Cast iron gate valves are frequently used in conduit systems to regulate the passage of various fluid media, including steam, gasoline, and water. It is mainly composed of cast iron, which imparts excellent resistance to corrosion and pressure.

Cast iron produces gate valves in applications with low pressure and temperatures. This material is often used to construct gate valves in HVAC (heating, ventilation, and air conditioning) systems and water and wastewater systems. Regarding subterranean applications, cast iron gate valves are preferred over steel valves due to their low cost

Cast Iron Globe Valve

As the water globe valve. It is designed for distribution and transportation systems in the water, air, hydrocarbon, and gas industries. Their bodies are constructed from ductile iron and feature integral flanges of two fundamental varieties. The stem actuating thread of the inside screw type is contained within the pressure envelope, and it does not rise. Typically used for non-corrosive and relatively hygienic applications, this valve type is shorter in height than the exterior screw variety. With the stem actuating thread positioned outside the pressure envelope, the outside screw, rising stem form is suitable for use in more active media where the fluid could potentially damage the thread.

Cast Iron Check Valve

The cast Iron check valve restricts flow to a single direction and automatically closes when the flow direction changes. It operates autonomously, relying on the flow velocity and differential pressure within the line to execute its opening and closing functions. Hot and cold water, HVAC, steam, gas, and general utility services are typical. Built from ductile iron of superior quality, the non-return valve exhibits exceptional durability and strength in the face of demanding operational circumstances. This valve’s extensive range of available diameters enables it to integrate effortlessly into various systems, ensuring an optimal flow control solution.

Cast Ductile Iron Ball Valve

As a result of their durability and strength, cast iron ball valves have several advantages over alternative valve materials. They can endure exceedingly high temperatures and pressures, rendering them well-suited for demanding industrial applications. Consequently, cast iron ball valves are commonly mandated across various industries to prevent the release of hazardous gases or substances. Furthermore, they are ideal for applications requiring this type of operation due to their incredibly quick and user-friendly operation, which can be initiated and terminated with a mere quarter-turn of the handle.

Cast Iron Butterfly Valve

A cast-iron butterfly valve’s name comes from the butterfly disc that turns in the middle of the valve and allows for fast shutoff in either a parallel or perpendicular direction to the stream. The disc is rotated perpendicular to the valve seat when fully closed, sealing off the channel. To make a Butterfly Valve work in tandem with the flow, it is necessary to turn the valve a quarter turn while it is completely open.

The butterfly-shaped disk is attached to a rod and is widely used. Whether the valve is open or closed determines the movement of the rod with the disc. Its high thermal cycle capacity and extreme heat resistance make it a perfect material for power plants. In addition, cast iron butterfly valves are strong, lightweight, and ideal for use in safe and dangerous settings.

Cast Ductile Iron Plug Valve

You can control gas or liquid flow by rotating the stopper with a hole in it. Cast iron, a long-lasting material known for strength and corrosion resistance, makes CI plug valves. A CI plug valve just requires a few simple steps to operate. When rotated, the fluid may flow through the plug so that its passage lines up with the pipeline, or it can be twisted to block the flow when positioned perpendicular to the pipeline. The plug may be turned to regulate fluid flow precisely or turn it off entirely using this rotary action. CI plug valves are great for dependable flow control in various applications. They can withstand tough environments because of the cast iron structure. The exceptional corrosion resistance of CI plug valves ensures their long-term functioning, regardless of the challenging conditions.

Cast Iron Diaphragm Valves

When closed, the elastomeric diaphragm of a diaphragm valve (also called a membrane valve) sits on a seat. As a device for controlling the flow of fluids, the flexible diaphragm may block, regulate, or isolate the flow.

The diaphragm element of a diaphragm valve may be bent upwards or downwards to alter the fluid flow rate. The valve is sealed when the diaphragm is firmly forced against the solid seat. One kind of valve that may be used to regulate and monitor the linear flow of fluids is the diaphragm valve.

Cast Iron Y Strainer Valve

If you want to eliminate solids in liquids, this device works. Its mesh catches impurities and stops them from moving, which keeps the system’s main parts safe. It can handle up to 6,000 psi of pressure and works with high-speed devices. On top of that, they need less upkeep and cleaning. A Y strainer protects the system’s main parts and covers tools further down the line. You can put this filter in either a vertical or horizontal position. When you set the y strainer in position, ensure the lower leg is down. This will keep contaminants from entering the system again.

Manufacturing Components Of Cast Iron Valves

The functionality of cast iron valves relies on several crucial components, making them sturdy and dependable for various uses. Important replacement components include the following:

Valve Body

The key component that retains pressure in a valve is the valve body, which contains the disk and seat. The valve body may also assist fluid passing the valve. The valve body is joined to the pipe at both ends. Depending on the size and pressure of the pipe system, these ends may be either flanged, threaded, or butt welded. Stainless steel, cast steel, and alloy steel are among the materials that may be used for valve bodies

Valve Disc

Based on its location, the disc either enables or blocks the flow. Discs used in plug or ball-type valves are known as plugs or balls, respectively. A valve disc may be cast, forged, or manufactured metal. Except for check and safety-relief valves, when fluid flow and pressure move the disc away from its seat, it is usually placed against the stationary valve seat or seats.

Stem

A stem is a solid rod or shaft that has been forged. The stem transmits the motion to the disc, plug, or ball to open or close the valve. It connects at one end to the valve disc and another to the valve handwheel, actuator, or lever.

Packing

A seal is created, and leaking along the stem is prevented by positioning packing material around the stem. It must be long-lasting, medium-resistant, and have a low-friction seal so the stem may move freely.

Actuator or Handwheel

A device known as the actuator controls the valve. The assembly of the stem and disk is fastened to it. You may use a handwheel, lever, gear, or chain to turn it by hand, or you can use a motor, solenoid, pneumatic, or hydraulic system to do it for you.

Seats

The primary parts that affect the valve’s leakage rate. A seat may be constructed from a non-metallic material, the forged ring, or even a built-in part of the valve body. There could be several seats in a valve. When using a globe with a swing-check valve, the disc and one seat create a seal to prevent flow.

Why We Select Cast Iron Valves

- Durability

The structural stability of ductile iron is remarkable. Without flinching, it can withstand extreme heat and pressure. This material’s flexibility makes it resistant to cracking under stress. While cast iron rusts more readily than ductile iron, both materials corrode over time.

- Corrosion Resistance

Ductile iron is naturally very resistant to corrosion. Coatings or linings may make these valves suitable for usage in hostile media or corrosive environments. This means they last longer before needing replacement, which means you can save bulk purchasing cost.

- Reasonable Price

Ductile iron valves are much more economical than other valves, such as alloy or stainless steel ones. Because of this, they are a great option for projects looking to save money without compromising performance or longevity.

- Multiple Uses

Water distribution, sewage treatment, gas distribution, and even certain chemical processes are just a few of the many uses for ductile iron valves. Several sectors prefer them because of their versatility in handling different types of material.

- Enhanced Flow Properties

Ductile iron valves provide better flow characteristics because their inside surfaces are smooth. This improves the system’s efficiency since it can manage greater flow rates with less friction loss.

- Ease of Installation

Because they are not as heavy as regular cast-iron valves, ductile iron valves are much easier to install. The project’s total cost may be reduced due to time and labor savings during installation.

- Impact Resistance

Due to their strong impact resistance, ductile iron valves resist shocks and impacts that would damage other valve materials. This is important because of the potential for hard handling in industrial settings.

- Long Service Life

Durability, resistance to corrosion, and tolerance for high temperatures and pressures contribute to the extended service life of ductile iron valves. This results in fewer replacements needed, which ultimately reduces maintenance expenses.

A Ductile Iron Uni-Directional Knife Gate Valve—What is It?

When dealing with semi-solid fluids that may include many suspended materials, such as slurry or viscous fluids, a particular kind of industrial valve called a Ductile Iron Uni-Directional Knife Gate Valve is used. This valve’s narrow, pointed gate is its defining characteristic; it cuts through fluid like a knife.

A material renowned for its exceptional strength, resistance to impact and corrosion, and endurance in harsh environments, ductile iron forms the valve’s body. As a result of its wear resistance and excellent fluid flow properties, ductile iron is an excellent material for knife gate valves.

Regarding general-purpose valves, a uni-directional knife gate valve is a cheap option that may be operated manually or with an actuator. It is also straightforward to use. Not only do these knife gate valves only seal on one side, but they only work in one direction.

Because of the blade’s cutting motion, they also tend to leak if there is a possibility of debris accumulation. Ideal for a wide range of slurries, including water, pulp, paper, mining, chemicals, some adhesive compounds, fly ash, and solids from sugar mills. Operating the knife gate valve in a one-way configuration is possible even in hot and hostile settings.

Gate Valve:

The cast-iron gate valves that contain water and support its pressure are known as gate valves. As well as enclosing the gate plate and providing support, the gate frame doubles as a chute that allows the plate to rise and fall. In the second step, the concrete of the gate pier and the bottom of the gate is set, which uniformly transmits the water pressure from the gate plate to these parts. This ensures that the outside section of the chute is properly supported.

Ball Valve:

A ball valve is a kind of shutoff valve that has a bore within the valve that enables or blocks the passage of liquids, gases, and vapors in a piping system by spinning the ball. A shaft links the ball to the operational and control mechanism that spins it, and the ball is positioned against two seats. Not allowed to pass through the valve when the bore’s cross-section is perpendicular to the flow region. The area of the hole exposed to the floor determines the fluid flow rate as it goes through the valve.

Butterfly Valve:

Regarding media flow control in pipelines, butterfly valves—which are quarter-turn valves—are ideal. Turning the valve handle to the right or left causes it to fully open or shut. As challenging as throttling may be, these valves are useful for regulation. The three main ways to open and close a butterfly valve are by hand, pneumatically, or electrically via an actuator. You can operate the valve with the aid of the actuator; just attach the actuator to the disc, and it will move the disc as needed.

Cast Iron Globe Valve

The Cast Iron Globe Valve is a spherical-body valve that uses a moving plug or disc element and a fixed ring seat to control fluid flow in a pipeline. The spherical form of the valves’ bodies, separated by an internal baffle, is the basis for their name. A removable plug may be put into the valve’s aperture, which serves as a seat. The most noticeable part of a Cast Iron Globe Valve is that the body is responsible for retaining the valve’s pressure and giving it its overall shape and size.

Check Valve:

A check valve is unique among valves because it relies only on the fluid dynamics inside the system to function. A disc or ball with hinges opens this valve in response to the correct fluid flow. The disc or ball will swing backward due to the pressure, forming a seal and preventing the fluid from trying to flow in the other direction. A check valve is used whenever there is a risk that backflow might harm delicate parts.

How Do Ductile Iron Valves Work?

We may learn more about the specific features and workings of Cast Iron Valves if we take a closer look at their mechanics and features.

Pipe Fitting Service and Ductile Iron Valves for Plumbing Systems

All plumbing systems, from homes to companies and factories, rely on cast iron valves and pipe fittings. Important tasks performed by these parts include:

Coupler: You may use a coupler to join two pipe lengths in a straight line. A coupler is required to reassemble a pipe that has been severed during a repair.

Bend: Used to change the direction of a pipe. Ninety degrees (or elbows) and forty-five degrees are the most typical bending angles. Unless it’s a PEX bend, which is metal or hard plastic, the material of the bend is usually the same as the pipe.

Union: Union is a detachable coupler type. Its large threaded nut fastens together the two pieces of the joined pipe. You may use one instead of a coupler for any design requiring temporary pipe disassembly.

Tee: The “T” shape is typical of tees with three ports: two parallel and one perpendicular. You may use it to add a branch line. Using a reducing tee allows for joining lines of varying sizes, such as branch and main lines.

Reducing adapter: A further method for connecting varying-sized pipes is the reducing adapter. It fits within the bigger pipe (plastic) or has a bell shape (copper and galvanized pipes). One is a reduction bushing, while the other is a bell adapter.

Compression fitting: A compression fitting removes the need for glue or solder when connecting pipes made of plastic or copper. Typically, one will see a nut fastened onto the fitting and a ring around the pipe, with the latter being wedged into the opening between the two. Pipes may be easily repaired using compression fittings. Compression fittings are standard on most contemporary water cutoff valves for faucets and toilets.

Threaded adapter: A threaded adapter must connect two pipes with different fastening methods, such as a glue or solder slip junction, to one with threads. The threads might be male or female. You may connect plastic pipes, copper, or brass using threaded adapters.

What Makes Cast Iron the Best Raw Material Choice?

Cast iron is more resistant to high pressures than almost any plastic. The problem is that cast iron pipes and valves may flex and shatter when the rated pressure is exceeded. Because of its low elasticity, cast iron is extremely stiff and easily cracked when bent. Regular maintenance keeps your valve free of corrosion; cast iron will also rust over time. Ductile iron has remarkable structural durability as well. It is completely unfazed by extreme heat and pressure. To further understand why ductile iron might be a better choice than these other materials, let’s take a closer look at the comparison:

Ductile Iron vs. Stainless Steel

For many reasons, stainless steel has recently surpassed all other valve materials in popularity. This metal’s excessive toughness, together with its very high resistance to oxidation and corrosion, makes it an excellent material for producing long-lasting valves. Stainless steel valves will not rust, regardless of the environment’s wetness. Because of this quality, they are an excellent option for areas near the shore where corrosion from seawater is a potential issue.

Stainless steel can withstand a broad temperature range and has an extraordinary corrosion resistance. The price is more than that of ductile iron, however. Ductile iron could be the better choice when cost is an issue or when strength is more important than corrosion resistance.

Brass vs. Copper vs. Ductile Iron

Compared with ductile iron, the softer metals copper and brass are much simpler. Their resilience to corrosion and excellent heat conductivity are other noteworthy qualities. But they can’t compete with the durability and strength of ductile iron. Ductile iron is, therefore, often the best material to use when dealing with high pressures or when the durability and longevity of the valve are crucial.

Ductile Iron vs. PVC

Lightweight, inexpensive, and highly resistant to corrosion are just a few of the advantages that Polyvinyl Chloride, or PVC, offers. Ductile iron is often more durable and strong than PVC. Ductile iron excels in environments requiring the management of high-pressure levels, but PVC may distort when exposed to high temperatures. Ductile iron is often used in situations that require handling at high pressure or excessive temperatures.

Standard Size Guide About Cast Iron Valves Manufacturing

A selection of diameters of ductile iron valves are available to accommodate a wide range of applications. The measurement of a valve’s dimension is conventionally denoted by its entrance diameter.

Ductile iron valves, also called cast iron valves, are essential elements in various industrial and residential systems. The primary consideration is the nominal diameter (DN), which denotes the diameter of the valve’s orifice, although they are available in diverse sizes. The dimensions of these valves vary from DN15 to DN50 (1/2 inch to 2 inches) to accommodate small-scale domestic use, such as in residential piping systems, to DN300 or more significant (12 inches or more) to accommodate large industrial applications.

The determination of size is not an arbitrary decision; instead, it is closely tied to the desired function, the nature of the fluid requiring regulation, and the pressure and temperature specifications. These variables significantly influence the determination of the necessary valve size and type. For instance, a valve featuring a more substantial body may be required when managing a high-pressure system. On the other hand, a low-pressure residential plumbing system may need a smaller valve.

DN50 (2 inches), DN80 (3 inches), DN100 (4 inches), DN150 (6 inches), DN200 (8 inches), DN250 (10 inches), and DN300 (12 inches) are a few examples of typical dimensions. However, these dimensions should not be regarded as definitive rules; the particular demands of your undertaking might necessitate an alternative measurement.

In addition, it should be noted that the dimensions of these valves may vary across countries due to the implementation of distinct standards. The British Standards Institution (BSI) is authorized to establish the standards for valve diameters in the United Kingdom. In contrast, the American National Standards Institute (ANSI) is accountable for this in the United States. Hence, prior knowledge and comprehension of the regional regulations and standards are imperative when selecting a valve size.

Manufacturers and valves consumers must comprehensively comprehend these measurement ranges and their respective applications. It aids in the design phase, guarantees the valve’s proper integration into the system, and enables accurate valve operation.

Butterfly Valve Design

Butterfly valves are characterized by their circular configuration and a disc or plate placement in the valve’s center. By rotating the disc 90 degrees, the fluid flow is regulated. When the disc is in the open position, it is oriented parallel to the direction of fluid passage, which provides minimal obstruction for fluid to pass through the valve. When the valve is closed, the disc undergoes a 90-degree rotation to assume a perpendicular position to the flow, impeding fluid passage.

Gate Valve Design

Typically, gate valves have a rectangular or circular body and an internal wedge or gate that regulates fluid flow by sloping up or down. The valve can be opened and fully closed by adjusting the gate or wedge along the vertical axis perpendicular to the fluid flow. With minimal obstruction, fluid can circulate readily through the valve when the gate is open. When the gate is entirely closed, it establishes an impenetrable barrier that thoroughly obstructs fluid passage.

Applications Of Butterfly Valves

With their adaptability and quick response periods, butterfly valves are appropriate for various applications, including large-scale fluid systems. Their compact dimensions and lightweight construction render them well-suited for confined conduit systems with significant spatial constraints. The shutoff capability of butterfly valves renders them well-suited for sectors requiring total flow cessation, including waterworks, chemical processing, and the food and beverage industries.

Applications of Gate Valves

Extensive use is made of gate valves in applications where precise flow regulation under extreme conditions is required. For example, gate valves are frequently utilized in the oil and gas sector because they control fluid passage in high-pressure and temperature systems. These valves are utilized when precise flow control is required in numerous industrial settings, including steam lines, water treatment facilities, petrochemical processing, etc.

Cast Iron Gate Valve Vs. Butterfly Valve

Gate and butterfly valves are integral to fluid control systems in numerous industries. These valves are utilized extensively in industrial settings to regulate flow. However, differentiating between the two varieties of valves is of utmost importance to use the appropriate valve for one’s particular requirements

Cast Iron Valve Vs. Ductile Iron Valve

The history and design of cast or ductile iron valves are linked to the larger story of the development of metallurgy, fluid dynamics, and engineering and heating systems, which are applications in industrial and commercial plumbing systems.

Cast Iron Valve

Carbon and silicon are incorporated into molten iron to produce cast iron. The distinctive grey color of cast iron is due to the carbon content of the material, which consists of graphite particles. Exceptional wear resistance, superior machinability, and affordability characterize cast iron. When strength and durability are essential, it is frequently applied to cookware, conduits, and engine blocks.

Ductile Iron Valve

A more recent alloy, ductile iron, was created in the middle of the 20th century. A minute quantity of magnesium is introduced into molten iron to induce the formation of graphite nodules instead of particles. This imparts flexibility, or the capacity to deform without fracturing, to the material. Ductile iron is renowned for its exceptional durability, resilience, and strength. Applications requiring flexibility and high strength include machinery, automotive components, and pipelines.

Comparison

Regarding durability, ductile iron is generally regarded as superior to cast iron. Cast iron is more brittle than ductile iron, even before thermal treatment. It is less susceptible to fracture upon impact. Due to its ductile nature, iron can be bent. Confrontationally, cast iron is more rigid. Due to its high hardness, it effectively resists surface erosion. Furthermore, wrought iron is superior at mitigating vibrations. The variations arise from the distinct graphite microstructures present in these iron alloys.

Ductile iron possesses exceptional yield strength, tensile strength, and corrosion resistance. In contrast to cast iron, ductile iron remains intact when bowed, rendering it more suitable for demanding applications. Top suppliers of cast iron products consistently exceed market standards through their tight attention to quality control and streamlined manufacturing processes.

Strength

Ductile iron is favored over cast iron for industrial applications because of its superior qualities. Conversely, cast iron is susceptible to breakage, rendering it unsuitable for specific applications. Furthermore, unlike ductile iron, cast iron cannot be bent without shattering and cannot elongate to the point where it loses its shape.

How The Cast Iron Valve&Can Be Manufactured In Industry

There are different types of cast iron gas valves, each with its advantages. The most common type is the gate valve, which controls gas flow by opening and closing a gate. Gate valves are available in different sizes and can be operated manually or automatically. Another type of cast iron gas valve is the ball valve, which controls gas flow by opening and closing a ball. Ball valves are available in different sizes and can be operated manually or automatically.

Step 1: Design of Cast Iron Valve

A few crucial design considerations must be considered when conceptualizing a ball valve. Before anything else, the ball must be capable of seamless rotation within the valve’s body to open and close as required. Furthermore, the valve’s seals must be robust and long-lasting, capable of withstanding elevated temperatures and pressures. Ultimately, the valve’s design should prioritize ease of operation and maintenance.

Step 2: Receiving of Raw Materials

Purchasing iron valve basic materials may seem challenging, but it can be accomplished with persistence and purpose. Before purchasing iron valve primary materials, ensure you are familiar with the valve’s type, size, pressure rating, and material composition. Before purchasing iron valve primary materials, consider the type of valve you will be constructing. Forged and cast iron are the two most prevalent varieties of iron valves. Because every type has benefits and drawbacks, selecting the proper valve type for your particular application is vital. The manufacturing procedure for cast iron valves entails the shaping of molten iron.

Step 3: Forging and Casting of Iron Valve

The first step in crafting an iron valve is shaping a billet of iron into the basic form of the valve. Iron is heated to a point where it becomes pliable during forging; then, it is shaped using hammers and other tools. The final shape of the valve is cast after its fundamental design is forged.

The technique of casting iron entails cooling molten iron in a mold before pouring it into the form. For an iron valve to turn out correctly in size and form, the mold must be meticulously planned. The valve may be placed after it has cooled and solidified.

Step 4: CNC Manufacturing of Iron Ball Valve

The use of mass computer numerical control (CNC) manufacturing for the production of ball valves offers several benefits in comparison to conventional manufacturing techniques. One notable benefit of (CNC) technology is its ability to facilitate accurate manufacturing of valve components. Consequently, this technique ensures much enhanced precision in the final dimensions of the valve compared to conventional methodologies. This aspect is significant as it guarantees the proper functioning of the valve and prevents any potential leakage.

One further benefit lies in the expedited nature of CNC machining compared to conventional techniques. This implies that more valves may be manufactured within a reduced timeframe.

Step 5: Assembly and Inspection

Because of its resilience and longevity, iron ball valves find employment in various sectors. Although there aren’t many complicated stages in making these valves, a few must be followed to guarantee a top-notch end result. The iron casting must be allowed to cool before assembly can begin. The valve body must be fastened to the handles before proceeding. Seats and seals are then put in place. After these components are in position, the ball may be put into the valve. At last, the packing nut and stem are fastened.

Before every valve leaves the factory, it must undergo a thorough inspection. This entails ensuring everything is in its proper place and inspecting the casting for any damage, such as cracks. If any issues are detected with the valve, it must be fixed or replaced before shipment.

How Can You Check The Quality Of A Cast Iron Valve

Ball valve quality control is essential for ensuring a high-quality product. Several fundamental elements comprise quality control:To fabricate ball valves, every material must be inspected to meet all applicable specifications. Component elements and basic materials are included.

Advantages of Using Ductile Iron as Valve Materials

Ductile iron is optimal for valve materials due to its numerous advantageous properties. Carbon content is at least 3% in ductile and cast iron but less than 0.3% in cast steel. Due to the minimal carbon content of cast steel, unbound graphite carbon does not precipitate in the form of particles. Cast iron naturally contains carbon in the form of free graphite particles. Unlike cast iron, ductile iron contains graphite as nodules instead of particles.

In contrast to cast iron and cast steel, the physical properties of ductile iron are superior. The rounded knobs hinder the formation of cracks, thus imparting the alloy with the enhanced flexibility for which it is named. However, particles in cast iron reduce the iron’s ductility. The flexibility is greatest when the ferrite matrix is utilized.

Absolute strength advantages are associated with ductile iron in comparison to cast iron. Ductile iron has a tensile strength of 60k, whereas cast iron’s is only 31k. Even though ductile iron has a yield strength of 40k, cast iron fails to exhibit this strength and eventually fractures.

Ductile iron possesses a comparable strength to that of cast steel. Ductile iron possesses a greater yield strength. Ductile iron has a minimum yield strength of 40k, whereas cast steel’s yield strength is 36k.

Its reduced cost is a significant factor in selecting ductile iron over cast steel for the valve material. The increased popularity of ductile iron can be attributed to its low cost. Additionally, choosing ductile iron can decrease the cost of machining.

Type and Size of Valve

The variety and dimensions of valves dictate the various applications for which they can be utilized. Valves can regulate the passage of fluids and gases, diverting, mixing, and stopping flow. Additionally, they can prevent backflow and release pressure. The type of valve selected is determined by its function.

The most prevalent valves are check valves, closure valves, pinch valves, regulators, relief valves, stopcocks, toggle valves, metering valves, needle valves, and ball valves. To arrive at the correct decision, the type and quantity of the valve must correspond with its intended function within the system.

Requirements for Performance

A valve is anticipated to function under varying pressure and temperature conditions. A quality valve should maintain optimal performance even when subjected to the system’s lowest and greatest temperatures and pressures.

In extremely pressurized systems, metal valves are superior to plastic valves, particularly when operating temperatures are elevated, because metals are more durable than polymers.

How do you select the right cast iron valve for your application?

This is crucial for the application’s stability and the valve’s dependability. Operating a malfunctioning valve is extremely hazardous, as it could result in gas or liquid leaks. The type of valve connection you select should also be considered, as it can vital impact the ease and quickness of replacement or repair. Every type of connection has its benefits and drawbacks.

Key points select the right cast iron valve

Understanding Your Requirements: Firstly, determine the purpose of the valve. Is it for regulating flow, preventing backflow, or completely stopping/allowing flow? The answer will help you decide the type of valve (ball, gate, globe, check, etc.).

Material Selection: A cast or ductile iron valve is a good choice if your application involves high pressure and temperature. Ductile iron has more strength and impact resistance than cast iron, making it suitable for more demanding conditions.

Size and End Connection: The valve size should match the pipe size it will be installed in. The type of end connection (flanged, threaded, socket weld, etc.) must be compatible with your system.

Operational Considerations: Consider how the valve will be operated (manually, electrically, pneumatically, etc.). This will help you decide if you need a simple lever-operated ball valve or a more complex actuated valve.

Standards Compliance: Ensure the valve meets relevant industry safety, performance, and compatibility standards.

Professional Installation: Hiring a professional installer ensures the valve is installed correctly and securely, reducing the risk of leaks and malfunctions.

Alignment: Ensure the valve is aligned correctly with the piping system for optimal performance.

Testing: Test the system under controlled conditions before fully turning on the flow.

Factory Self-Nomination Why Plumberstar as the Best Cast Iron Valve Supplier?

Plumberstar must be included among the high-quality residential valve manufacturing companies in China. Since 2006, We have offered plumbing and thermal options for residential supplies. In addition, Plumberstar offers pipe and valve fitting solutions built to meet the requirements of your business. These solutions are the result of combining innovative thinking with exceptional craftsmanship. Devoted personnel exert ceaseless effort in comprehending customers’ requirements, producing products that adhere to benchmarks and set your organization apart from competitors. This organization produces valves using high-quality components and distributes its goods globally. We offer an extensive selection of valve designs to accommodate your particular requirements.

We guarantee a smooth and uninterrupted experience, from customer acquisition until post-purchase support. Our competitive pricing and superior quality give your investment the utmost value. Our production methods are based on our commitment to ecological sustainability. Durable valves manufactured by Plumberstar reduce replacement frequency and contribute to environmental friendliness. Consider us for value, quality, and sustainability.

The Frequently Asked Questions About Cast (Ductile) Iron Valves

Please note that are common questions from most customers. Could you please feel free to contact us if any further questions or are confused about Ductile (Cast) iron valves?

What Is The Maximum Operating Temperature Of Cast Iron Valves?

The cast iron globe valve is frequently employed in water distribution, heating, and water at minimum and maximum temperatures ranging from -10 °C to +300 °C. The valve stem is not in contact with the fluid. Hermetically, the valve is sealed off from the atmosphere.

Do Cast Iron Valve Rust Over Time?

Extreme care is required due to the susceptibility of a cast iron valve to corrode and the likelihood that it has been in place for decades. Cast iron valves are typically encased in corrosion and often rendered immobile

Can Cast Iron Withstand Seawater?

Although galvanized steel and cast iron resist salinity, they will rust with prolonged exposure. Plastic is the most resistant to corrosion by saline water. However, preventive measures exist to safeguard pipelines against corrosion caused by salinity in water.

available else

What Is The Distinction Between Carbon Steel And Cast Iron Valves?

Carbon content is the primary distinction between cast iron and cast steel valves; it directly impacts the steel's plasticity and strength. Carbon steel, an iron-carbon-alloy with a carbon content of less than 2% WC, is also known as carbon steel.

What Are Cast Iron Valves Used For?

Plumberstar cast iron valves find extensive application in diverse sectors, such as drainage and air conditioning systems within buildings, fire suppression equipment, water and wastewater pipelines, and utility systems across multiple industrial facilities.

Is Cast Iron Resistant To Pressure?

Compared to plastic, cast iron is a durable material capable of withstanding more significant pressures. However, cast iron can bend and break if the pressure rating of a valve or conduit is exceeded. Due to its nearly non-ductile nature, cast iron is rigid and will shatter when bent.

Are Cast Iron Valves Environmentally Friendly?

The potential for recycling cast and ductile iron makes valves constructed from these materials more ecologically sustainable than those composed of non-recyclable components. As a result of their extended lifespan, replacements are required less frequently, which reduces waste production.

How Much Pressure Can Cast Iron Valves Withstand?

The two most prevalent are courses 125 and 250. The rated pressure range for class 125 cast iron flanges at moderate temperatures is between 150 and 200 psi. Class 250 cast iron is marginally more durable, with a 500 to 300 psi. The pressures may differ depending on the sort of finish.

Is It Possible to Replace the Cast Iron Valve Components?

Whether the components need to be replaced depends on the cast iron valve's location, nature, and size. The connection valve component of a cast iron valve is exceedingly difficult to locate. Although a minority of water contractors may possess some spare parts, the vast majority are no longer manufactured or available. In this instance involving the leading joining moist connection valve, the cast iron valve must be disconnected from the main water supply. It must be replaced with a new moist connection valve made of ductile iron whose diameter surpasses 2.5 inches.

What specific maintenance must be performed on the cast iron valve within the water Pipeline?

The valve is corrosive and becomes brittle due to the cast iron composition. The operation of the cast iron valve presents several complications, requiring specialized inspections to avert pipeline destruction.