Description

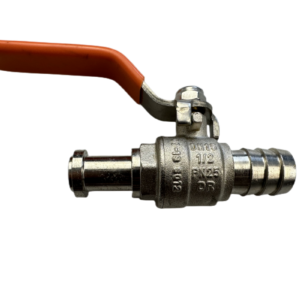

Mini Ball Valve

JX-0440

- Brass Mini Ball Valve

- Lead-free brass and DZR

- Working pressure of 125 psi

- Female x Male; NPT, BSP

- 1/2″FXM

- A double-seal system and heavy-duty aluminum Alloy handles allow the flow to go in either direction.

- Working temperature of 2°F to 175°F, Fast 1/4 turn open or closed operation

- Each valve is individually tested for maximum safety for heavy-duty water, oil, and gas.

Mini-ball valves are quarter-turn ball valves used to close the fluid flow in the pipe work. It has to turn the handle to a right angle when the user wants to close or open the valve. One finds male or female threads on one side of this thread end ball valve. One can use the mini-ball valve to get through tight spaces when one might not require a larger-sized valve. They are used in hot, cold, and compressed air systems for household and small enterprise applications.

Raw Materials Used for Manufacturing the Mini Ball Valve

Consequently, material selection in the choice of a mini-ball valve is a factor that must be taken into quite considerable account. Various materials produce different distinct properties and applications.

The material used for constructing these small valves is also commonly stainless steel, PVC, and brass. While possessing greater flexibility and lighter construction, which make it ideal because of its low thermal expansion property, stainless steel is solid with high corrosion resistance.

Brass is the most utilized material in the production of mini-ball valves. Brass is a high-grade material that is durable, corrosion-resistant, and robust. It also finds widespread use in many industrial, medical, automotive, and piping applications and is cheap. These make brass the best choice for a wide range of different projects that require reliable performance out of their micro ball valves.

Choosing a Mini Ball Valve

A wide range of specifications and choices are present in miniature ball valves. These alternatives offer the capacity to select the optimal ball valve.

Size; 1/4″,3/8″ and 1/2″

Thread; FemalexFemale,FemalexMale.

Four-way and five-way ball valves:

Four-way and five-way designs are also included in Mini Ball valves. There are either four or five potential flow connections. The most prevalent ball porting is present in these multi-port valves. It renders them appropriate for diverting or mixing flow.

Diverter valves with an “L” or 90-degree opening that permits flow are known as five-way ball valves. This flow occurs between the bottom or standard port and one side port, but none of the other ports are involved.

One-way or unidirectional vs. two-way ball valves:

A two-port ball valve is a more frequently employed micro ball valve. It is equipped with two terminals or connections. The flow direction differs substantially between a one-way and a two-way ball valve.

A particular flow direction characterizes one-way ball valves due to its exclusive function of sealing and managing pressure in a single direction. A single chamber is always present to secure a one-way valve ball. This seat is designated for use in opposition to the ball.

Additionally, mini-ball valve covers provide a surface. It exerts pressure on the object. The cost of unidirectional ball valves is lesser. Two-way ball valves can manage the pressurized flow. They can work without the valve components experiencing premature degradation or leakage.

Three-way diverter (L-port) vs. mixing (T-port) ball valves:

The spheres within miniature three-way ball valves are designed in two distinct ways. The first is an L-port, while the second is a T-port. The two ball port varieties are oriented either vertically or horizontally. The openings of L-port three-way ball valves are shaped like a “L.” The passage of T-port three-way ball valves is shaped like a “T.” Diverter valves are L-port valves. They can redirect flow between various endpoints.

How Do You Test Mini-Ball Valves?

Frequently, mini-ball valves are implemented in smaller applications that necessitate more precise control. It is crucial to find a model that is suitable for the application and suits your needs, as they are available in various designs.

Before testing a micro ball valve, verify it is compatible with the piping system. Open the valve wide to observe the pressure accumulating in your plumbing system. Connect the valve to the pressure-reducing valve or relief valve. If there is excessive pressure, gradually close the valve until the pressure is reduced to an acceptable level. If the valve lacks a shutoff valve, installing one before placing it in service in your application will be necessary.

Another method of testing microball valves is to employ a gauge probe. Carefully observe the gauge reading as you insert the probe into one of the apertures and open and close the valve. Make sure that all terminals are accessible to ensure that the readings are precise.

End Connection of Mini Ball Valve

Mini ball valves may be positioned at any angle or orientation. Enough space is available for the lever’s 90-degree operation. The valves operate when installed in an erect position.

Threaded Connections:

An omit fitting should be of the appropriate dimension for the pipe. We must secure it. Then, secure the valve by screwing it. Spanner flats should be situated adjacent to the pipe connection. To prevent any pressure, both extremities must receive appropriate support.

Compression-end:

The pipe’s end must be square and free of any defects. Unscrew the fastener. Next, please insert it into the fitting until it reaches the pipe stop. Slide the olive and nut back onto the fitting. Tighten your hand until it is unable to rotate.

Mini Ball Valve Life Expectancy

Any ball valve can experience substantial wear and strain. The rotation operation of most ball valves results in their failure due to their nearly constant use. The rotation is typically 1/4 turn from a shaft that is affixed horizontally.

It rotates around its right angle axis about the cylindrical opening. Sometimes, mini-ball valves cease to operate because they have exceeded their expected lifespan of eight to ten years. Mini-ball valves may malfunction due to corrosion within or near the valve.

Ball valves can deactivate a fixture to regulate the passage of substances or gases. A rotary ball valve, which is a type of ball valve, is responsible for the regulation of fluid or gases. The bore of rotary spheres can open and close to either restrict or permit fluid passage. Please feel free to contact us if you have any further valve requirements.