Description

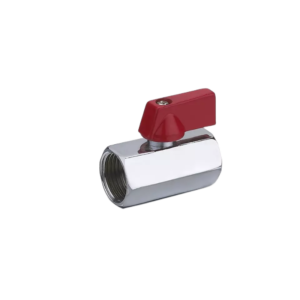

OEM Flange Ball Valve Body

JX-0410

Material; Brass material

CW617N, CW602N, Nickel bronze, Aluminum bronze, and C37700

Function; Control flow switch

Technical type; Die casting and forging

Connection: Female to male thread

Size: 1/2″-4″/OEM

Max pressure: PN60

Working Temperature: -10℃-150℃

Standard or Nonstandard: Standard

OEM Flange Ball Valve Body

OEM Flange Ball Valve Body is an important component of many industrial systems. It is used to regulate the flow of fluids and gases through pipes and other devices in various applications. The flange ball valve body comes in several different materials, including stainless steel, brass, carbon steel, and bronze, allowing for various uses. The flange ball valve body has some distinct features that make it ideal for industrial applications.

First and foremost, the body is designed to be strong and durable to withstand high-pressure levels without leaking or cracking. The flanges can be made from various materials depending on the application. This allows for better sealing capabilities as well as easier installation and maintenance.

Types of Valves: Threaded, Socket Weld, and Flanged Valves

An OEM flange ball valve body is integral to a fluid-control system. It directs and regulates the flow of liquids, gases, or steam. Many types of valves can be used in these systems, including threaded, socket weld, and flanged valves. Threaded valves have threads on their exterior that allow them to screw into a pipe or fitting. Socket weld valves use a socket weld connection that connects two pieces by melting both parts simultaneously. Flanged valves have flanges that allow them to join two pipes on their exterior faces. Each type has advantages and disadvantages depending on the application for which it is being used. Threaded and socket weld valves are excellent for low-pressure applications. In contrast, flanged valves are better suited for high-pressure applications due to their increased strength and durability than threaded or socket weld options.

Features of a Flanged Ball Valve Body

OEM Flange Ball Valve Body has many features that make it an attractive solution for industrial applications. This type of valve body offers superior performance and reliability, making it the perfect choice for many systems. Its features include:

One key feature is its design. This type of valve body uses a flanged connection to join two pipes, making installation more accessible and efficient than other valves. The flange also provides better sealing capabilities, ensuring no leaks occur in the system. Furthermore, this type of valve body is highly resistant to corrosion and abrasion due to its stainless steel construction, allowing for longer-lasting functionality in harsh environments.

Another great feature is its versatility. The OEM Flange Ball Valve Body can be used with various media types, such as gases and liquids, making it suitable for many industrial operations.

Advantages of OEM Production

As manufacturers look to reduce costs and increase production efficiency, OEM (original equipment manufacturer) production has become increasingly popular. OEM production is a process wherein a manufacturer purchases parts or components from another supplier and assembles them into an end product. In the case of the OEM flange ball valve body, the supplier provides the raw material, which the original equipment manufacturer then machines into its finished form.

OEM production offers many advantages over traditional manufacturing processes. It cuts down on costs associated with purchasing individual parts or components and assembly time. Additionally, it allows for greater flexibility when it comes to customization. Since a separate source provides the raw material, manufacturers can tailor their products more closely to meet specific customer needs without producing each component.

Customization Options for OEM Valves

Customization Options for OEM Valves is a must-read article for anyone looking to customize the construction of their OEM valves. Whether searching for a flange ball valve body or any other type of component, it’s essential to know the different customization options available. Customizing your valve parts can improve efficiency and effectiveness with the proper knowledge and understanding.

When purchasing OEM valves, customers often want an edge over competitors and increased performance from their systems. Customization options range from specific dimensions and materials to more complex modifications such as powder coating or specialized coatings designed for extreme conditions. These modifications require expert advice to ensure that all components are compatible with one another, providing maximum strength and durability throughout their lifetime.

Materials of Flange Ball Valve Body

OEM Flange Ball Valve Body is a highly specialized type of valve used in various industrial and commercial applications. It features two separate pieces that connect to form an airtight seal when the ball inside the valve body is turned. The materials used to construct OEM Flange Ball Valve Bodies are of paramount importance, as they must withstand long-term use and provide superior performance under extreme conditions.

The most common material for OEM Flange Ball Valve Body is stainless steel. This metal has excellent corrosion resistance, high durability, and low thermal expansion coefficients, making it perfect for this application. Stainless steel has excellent machinability, allowing for precision manufacturing processes and tight tolerances on parts. Other materials such as aluminum, brass, bronze, or even titanium may also be used depending on specific customer requirements or environmental considerations. Contact us for a quote if you need to replace the OEM Flange Ball Valve Body in your high-pressure system. We can supply you with a replacement part identical to the one that came with your unit, or we can provide you with a custom solution.