Description

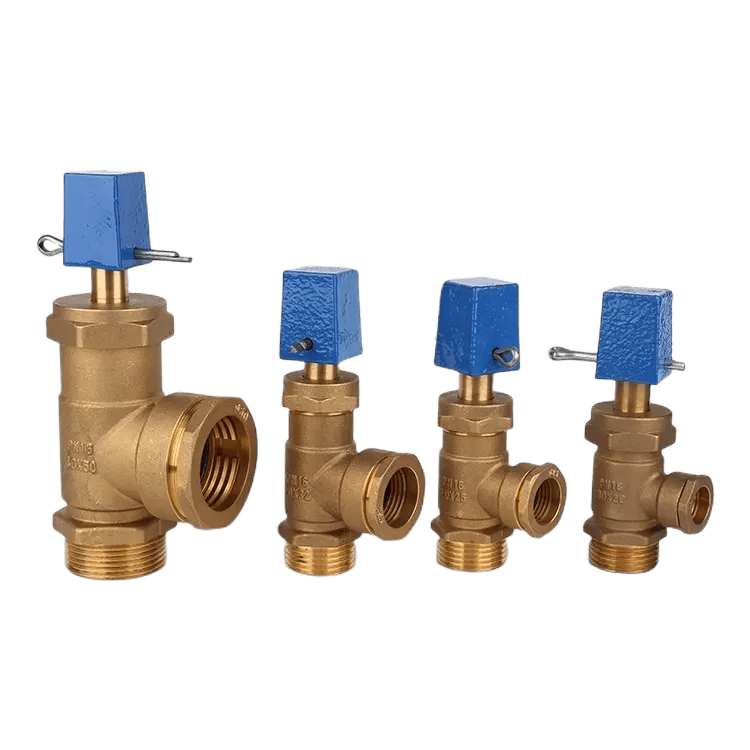

Compression Plumbing Angle Valve

JX-0203

Stop & Waste Valves, Washing Machine Valves, Water Heater Service Valves, Kitchen Gas Shut-Off Valves, Globe Valves

OEM, ODM, OBM

Power: Manual

Media: Water

Port Size:20mm- 50mm

Structure: Angle

Product name: Stop Angle Valve

Material: Brass Body

Connection: FemaleXMale Thread

Plumbing Angle Valve Basics

Plumbing angle valves are an important part of every plumbing system. Used in various applications like sinks, toilets, and showers, it is essential to understand the basics behind these valves. The simplest form of an angle valve is a compression plumbing angle valve and consists of a body, handle, bonnet nut, and seat washer.

Compression plumbing angle valves are typically constructed from brass or chrome-plated brass for durability and performance. The body includes two ports that control the flow of water through the valve – one inlet port to deliver water from the main line into the fixture and one outlet port to carry used water away from the fixture. A durable handle connects directly to a stem connected to the valve’s interior mechanics, enabling you to open and close the valve quickly.

Working Mechanism

Compression plumbing angle valves are an essential part of modern plumbing systems. Working with water pressure, these valves regulate water flow and allow precise adjustment to suit various individual needs. Understanding their primary working mechanism is essential for ensuring efficient operation and avoiding potential issues.

In a compression plumbing angle valve, a rubber seal is held by the stem at the center of the valve body. When opened, the stem pushes away from its seat, allowing water to pass through it. A nut on top of the valve body controls the force of this movement. By turning it clockwise, you can increase compression, which tightens the seal against its seat and reduces the flow rate; conversely, turning it counter-clockwise decreases compression and increases the flow rate.

Installation Process

Installing a compression plumbing angle valve can be difficult for those with little to no experience in home improvement projects. However, with the proper steps and knowledge, the installation process can be done quickly and efficiently. Before beginning this project, it is essential to have all the necessary tools, such as an adjustable wrench, plumber’s tape, and a Teflon paste. Additionally, some additional supplies may be needed depending on the type of angle valve being installed.

When tackling this project, the first step will generally involve disconnecting any existing supply lines and drain pipes currently connected to the area where the new angle valve will be placed. Once these have been removed from their current locations, they should be attached to either side of the new angle valve before being secured using the plumber’s tape and Teflon paste.

Potential Issues with Angle Valves

Angle valves, also known as compression plumbing angle valves, are a type of valve used to control liquid flow within pipes. While they are often the go-to choice for many plumbers and homeowners alike, some potential issues can arise with their use.

The biggest issue to be aware of is the possibility of leaking. Angle valves have several parts that must be tightly secured to remain effective; if these parts become loose over time, it could lead to leaks which could cause extensive damage and costly repairs. To avoid this issue, the angle valve must be properly installed and regularly checked for signs of wear or damage.

Another potential problem is corrosion due to exposure to water and other liquids over time.

Conclusion: Best Choice for Compression Plumbing

The Compression Plumbing Angle Valve is the best for compression plumbing and is a PEX angle valve. It is the most reliable and durable option, offering superior performance compared to other options. They are easy to install, highly efficient, and provide excellent corrosion protection due to their stainless steel construction. Additionally, they are made of high-grade brass that resists rusting over time and ensures a longer lifespan than other materials. Plus, they come in various sizes and styles, so there is something to fit any need or aesthetic preference.

PEX angle valves provide superior reliability through superior pressure ratings and temperature controls. This feature ensures that your plumbing system will remain safe from potential damages caused by higher water pressure or extreme temperature fluctuations.

Angel valve Inspection Methods.

For different types of valves, further tests can be performed. Let’s look at the associated valves tested via the procedure.

- For pressure relief valves, we perform a valve seat leakage test. It works by targeting the valve seat to notice leakages.

- Valves having backseat elements undergo backseat inspection. Gate valves and globes valves generally fall under this category.

- A shell leakage inspection is done for shut-off valves and those wholly open or close. Check valves, isolation valves, and stop valves are applied to this testing.

- A closure inspection can be made to check the valves’ closing mechanism. We can do it for almost all types of valves. Yet, gate valves, globe valves, plug valves, check valves, and ball valves agreed to this testing.

Materials of Valve Parts from Plumberstar

No. Part Materials 1 Body Brass with Chrome 2 Cartridge Brass 3 Stem Brass 4 Seal EPDM/cartridge 5 Seal Gasket NBR 6 O ring NBR 7 Thread BSP,G 1/2″x2″ 8 Handle Wheel Steel 9 Finish Sandblasted

Angle Valve Inspection Procedure.

Angel valve inspection can be carried out in a few easy steps. For hydrostatic angle valves, the following procedure is the simplest one.

- Start by filling the body of the valve with a testing fluid. It gets served at an optimal fixed temperature.

- Pressure is applied to the fill valve for about a minute (or more).

- The pressure will cause the water to come out of leakages.

- Physical instruments are used to measure the location where leakages occurred. Either on the stem, seat, or gasket.

The final testing gives an exact estimate to determine the damages in valves.

Final Remarks on Inspection Of Angle Valves:

Angle valve inspection is a necessary function to perform. Their maintenance is highly crucial. If you compromise on quality and working, you will have to keep changing valves to lose their working ability. It would help if you kept checking your valves for better performance and a long working time.

The best way is by inspection of valves. You can do it in a few steps. A little more consciousness can help your products last long. You can inspect the entire valve at once. By adding instruction liquid, it gets easier. Also, you can perform different types of tests for each category of angle valve type. There are a lot of options.

Inspecting each component of the angle is even a great idea. It can tell you about the exact location of the malfunction. You can only replace that part and save the rest.

This article is aimed to teach you about angle valve inspection. Reading and understanding it will make you quickly inspect angle valves at your home.

Read on Plumberstar: