Description

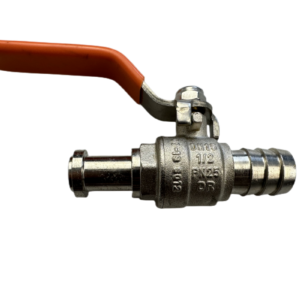

600 WOG Bronze Ball Valve

JX-0423

- Brass Bronze Ball Valve

- 2 pc with full port

- Brass ball and brass stem

- PTFE Sealing Ring

- Easy to install and operate

- Long service life

- Resistant to low temperature, humidity, and mechanical impacts

- Applications:cold-hot water installations, oil, and flammable gasses

- Temperature: Min. -10℃ / Max. +110℃

- Suitable for water supply systems, civil construction piping systems

- 90-degree valve closing range, the handle can close the valve by rotating it to either side of the valve body

-

600-WOG bronze ball valve

-

What’s a ball valve?

A ball valve is a shut-off valve that controls the flow of a liquid or gas employing a rotary ball having a bore. The medium can flow through or is blocked by rotating the ball a quarter-turn (90 degrees) around its axis. They are characterized by a long service life and provide reliable sealing over the life span, even when the valve is not in use for a long time. As a result, they are more popular as shut-off valves than gate valves. Moreover, they are more resistant to contamination.

- Floating valve: The ball of the floating 2-piece ball valve is bouncing around. The ball may produce a specified displacement and press on the sealing surface of the outlet. It all ends under medium pressure ensuring the outlet end’s sealing. The floating ball valve has a straightforward design and excellent sealing capabilities. The ball-bearing working medium load is passed to the outlet sealing ring. So check whether the sealing ring material can sustain the ball medium’s working load. This design is standard in medium and low-pressure ball valves.

- Advantages of the 2-piece complete port valve: The 2-piece ball valve is commonly used in the pipeline to cut off and distribute. Also, change the flow direction of the medium. Ball valves are a new form of valve that has recently gained popularity. The ball valve structure is essential. The sealing ring is movable and easy to disassemble and replace.

- When the valve is fully open or closed, the ball and valve seat sealing surfaces are always isolated from the medium. And the medium will not cause valve-sealing surface erosion.

- A broad range of applications. With diameters ranging from a few ml (millimeter) to several meters. Also, pressures range from high vacuum to high pressure. The entrance and outlet of the ball should be spherical when rotated 90 degrees to cut off the flow.

- The video from CraneBSU

-

- The fluid resistance is low, with the same resistance coefficient as a pipe of equal length.

- The structure is simple, with a modest volume and low weight.

- It’s lightweight and dependable. The sealing surface of the ball valve’s material is commonly used in plastic. And it has wide usage in vacuum systems.

- It’s simple to use and opens and closes. 90-degree rotation is mandatory when turning from full open to full close. It is convenient for remote control.

Only a 90-degree rotation and a small amount of rotating torque are necessary to seal the ball valve. The equal internal cavity of the valve body provides the medium with minimal resistance and a straight flow path. Ball valves are generally used for direct opening and closing. But, they have been available to throttle and control flow in recent years. Ball valves are well-known for their small size and low maintenance: water, solvents, acids, natural gas, and other standard working media. The working conditions of media like oxygen and ethylene are all suitable. The valve’s body might be integral or mixed.