Are you searching for the perfect valve solution for your next project? Have you ever considered using a 3-way valve but aren’t sure how it works? Look no further! In this comprehensive guide, we’ll explore the ins and outs of the valves and help you decide if it’s the right choice for your needs.

A 3-way valve is a versatile and efficient solution for controlling fluid flow in various applications. It allows for the mixing or diverting of fluid, making it a popular choice in industries such as HVAC, plumbing, and chemical processing. Let’s dive into the world of valves and uncover their key features, types, and applications.

What is a 3-Way Valve?

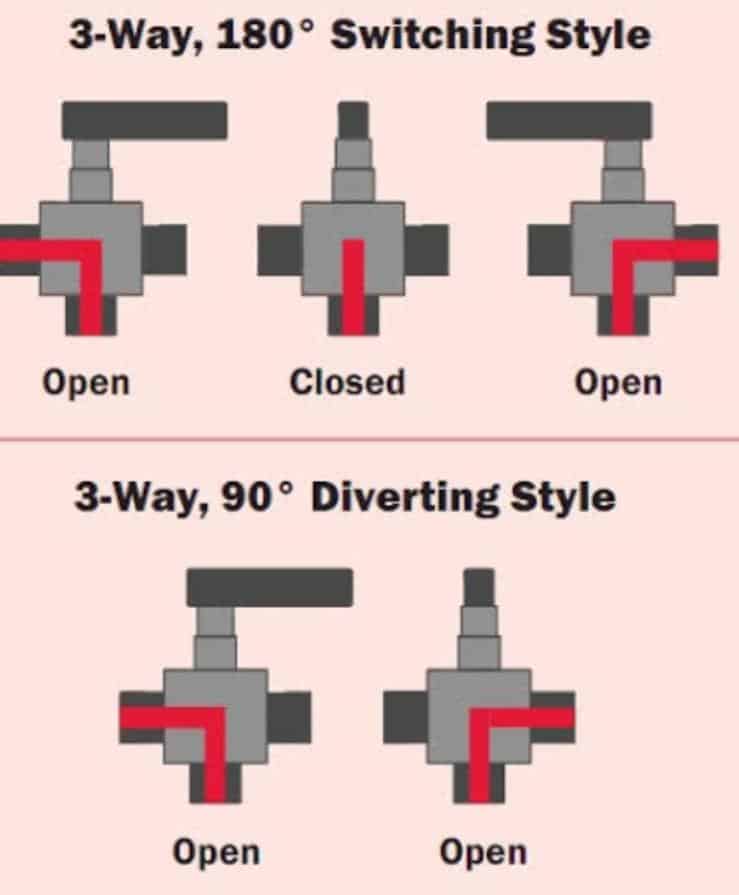

A 3-way valve is a type of Valve designed to regulate fluid flow through a system by mixing or diverting it. It consists of three parts, labeled A, B, and C, and a mechanism for controlling the flow between these ports. These valves can be either manual or automated with 90° and 180° turn on and off in 2 styles; they come in various materials, such as brass, stainless Steel, and cast iron.

How Does a 3-Way Valve Work?

The basic operation of a 3-way valve involves the opening and closing pathways between its three ports. The Valve can mix the fluid flow between ports A and B, allowing it to exit through port C or divert the flow from port A to either port B or C. The exact function of the Valve depends on its design and the specific application it’s used for.

Working Principles of 3-Way Valves

3-way valves are designed to control the flow of fluids or gases through a system by redirecting or mixing flow paths. Depending on the Valve’s position, they have three connection ports: one standard port and two other ports that can be connected or disconnected. By turning the valve handle or actuator, you can control the fluid flow between these ports, allowing you to mix, divert, or shut off the flow as needed.

Functions of 3-Way Valves

3-way valves are designed to perform several critical functions in fluid control systems:

Mixing: They can combine two separate fluid streams into a single output. This is useful in applications like temperature control in heating systems, where hot and cold water must be mixed to achieve a desired temperature.

Diverting: 3-way valves can slow the flow of a fluid from one path to another, allowing for a change in direction without the need for multiple 2-way valves. This is especially beneficial in applications where space is limited, or the system’s complexity must be minimized.

Bypassing: These valves can create a bypass route, allowing fluid to flow around a specific section of the system. This function is crucial in systems requiring regular maintenance or where a parallel flow path is needed to maintain consistent pressure or temperature.

Advantages of 3-Way Valves

There are several key advantages to using the valves in your fluid control systems:

Increased Versatility: With the ability to mix, divert, and bypass fluid flows, 3-way valves offer greater control and flexibility than 2-way valves, which can only open or close a single flow path.

Simplified System Design: By using a single 3-way valve instead of multiple 2-way valves, the overall complexity of your system can be reduced, leading to fewer potential leak points, easier installation, and lower maintenance requirements.

Efficiency Improvements: The precise control offered by 3-way valves allows for more accurate flow regulation, resulting in improved system performance, energy savings, and reduced operating costs.

Compact Design: Many 3-way valve designs, such as ball and butterfly valves, are compact and space-saving, making them an ideal choice for installations with limited space or where weight is a concern.

What Are the Different Types of 3-Way Valves?

There are two primary types:

Mixing Valves: Mixing valves are designed to blend fluids from two separate sources. They are commonly used in HVAC systems to regulate temperature by mixing hot and cold water or in chemical processing to combine two different substances. In a mixing valve, fluid enters ports A and B and exits through port C.

Diverting Valves: Diverting valves work by directing fluid from one source to either of two destinations. They are often used in plumbing applications to direct water flow between multiple fixtures or in industrial settings to control fluid distribution. In a diverting valve, fluid enters through port A and is referred to either port B or C.

Styles

There are several types of 3-way valves, each with unique features and benefits:

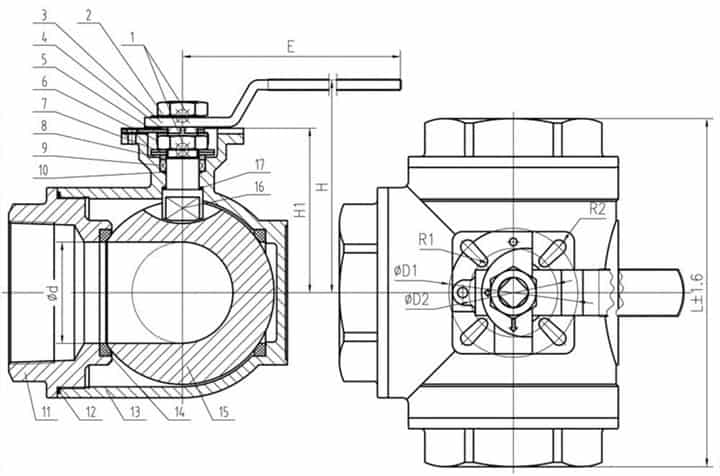

- Ball Valves: These valves use a rotating ball with a hole through it, allowing fluid to flow when the hole aligns with the flow path. Ball valves are known for their durability, low maintenance, and quick shut-off capabilities.

- Globe Valves: Globe valves use a movable disk to control the flow of fluids, providing precise control over the flow rate. They are well-suited for throttling applications and are often used in HVAC systems.

- Butterfly Valves: Butterfly valves have a rotating disk that can be turned to regulate flow. They are known for their compact design, ideal for tight spaces and large-diameter pipes.

When Should You Use a 3-Way Valve?

We need to mix or divert fluid flow in your system.

We require precise control over temperature or fluid distribution.

The application calls for a versatile and customizable valve solution.

3-way valves offer a highly versatile and efficient solution for controlling fluid flow in a variety of applications. With their ability to mix or divert fluids, they can be a valuable addition to HVAC systems,

What Are the Key Features?

- Versatility: 3-way valves can be used in various applications, from HVAC systems to chemical processing and beyond.

- Customization: As a leading valve manufacturer, Plumberstar offers a variety of materials, sizes, and pressure ratings to ensure a tailored solution for your specific needs.

- Quality Assurance: Our 3-way valves undergo rigorous quality control processes, including 100% product pressure testing, guaranteeing the highest performance and durability standards.

- Expert Support: Our knowledgeable team is available to provide technical assistance and guidance, ensuring a seamless experience from start to finish.

Materials: Brass, Stainless Steel, and Cast Iron

3-way valves are available in various materials, each offering unique benefits depending on the application:

Brass is known for its durability, corrosion resistance, and excellent heat conductivity, making them ideal for heating systems and plumbing applications.

Stainless Steel: valves offer exceptional corrosion resistance, making them suitable for use in harsh environments or with aggressive fluids, such as in chemical processing or marine applications.

Cast Iron: valves are economical, providing high strength and durability, particularly suited for water and wastewater management applications.

Temperature and Pressure Ratings

The temperature and pressure ratings of 3-way valves vary depending on their material and design. Generally, brass and stainless steel valves can handle higher pressures and temperatures than cast iron valves. Selecting a valve with appropriate ratings is crucial to ensure optimal performance and safety in your specific application.

| 3 way Valve Material | Working Pressure (Max) | Working Temperature Range | Typical Valve Sizes |

| Brass | 600 psi | -40°F to 400°F | 1/4″ to 4″ |

| Stainless Steel | 1500 psi | -320°F to 1000°F | 1/4″ to 12″ |

| Cast Iron | 250 psi | -20°F to 450°F | 2″ to 24″ |

| Bronze | 600 psi | -40°F to 550°F | 1/4″ to 12″ |

| PVC/CPVC | 150 psi | 0°C to 60°C (PVC) / 0°C to 93°C (CPVC),32°F to 140°F (PVC) / 32°F to 200°F (CPVC) | 1/2″ to 12″ |

Spec At Plumberstar, we offer customized home valve and pipe fitting products tailored to your unique requirements, including working pressure, temperature, and size specifications. factions: Size and Connection Types

3-way valves come in various sizes, typically ranging from 1/2 inch to 2 inches, to accommodate different flow rates and pipe sizes. Depending on your system requirements, connection types can include threaded, flanged, or soldered connections.

Applications: Mixing, Diverting, and Beyond

3-way valves applications;

- HVAC systems: Regulating temperature by mixing hot and cold water or glycol solutions.

- Plumbing systems: Directing water flow between multiple fixtures or appliances.

- Chemical processing: Combining or diverting aggressive fluids or chemicals.

- Industrial fluid control: Managing the distribution of liquids or gases in various processes.

Full Port or Reduced Port for the 3-Way Valve

When selecting a 3-way valve, you’ll need to consider the type of port configuration that best suits your application. There are two primary port configurations: full port and reduced port.

Full Port:

A full port 3-way valve, also known as a full bore valve, features an internal diameter equal to the pipe’s internal diameter. This configuration ensures minimal flow restriction, lowering pressure drop and reducing energy consumption. Full port valves are ideal for applications where maintaining a high flow rate is crucial.

Reduced Port:

In contrast, a reduced port 3-way valve has a smaller internal diameter than the pipe, restricting the flow. This design leads to an increased pressure drop across the Valve, which can be advantageous for specific applications, such as flow control or throttling. Reduced port valves are generally more compact and lighter in weight, making them a suitable choice for space-limited installations.

At Plumberstar, we provide both full port and reduced port 3-way valves in various materials, sizes, and pressure ratings to cater to your specific requirements. Our team of experts will work closely with you to determine the best port configuration for your application, ensuring optimal performance and efficiency.

T-Port vs. L-Port Valves:

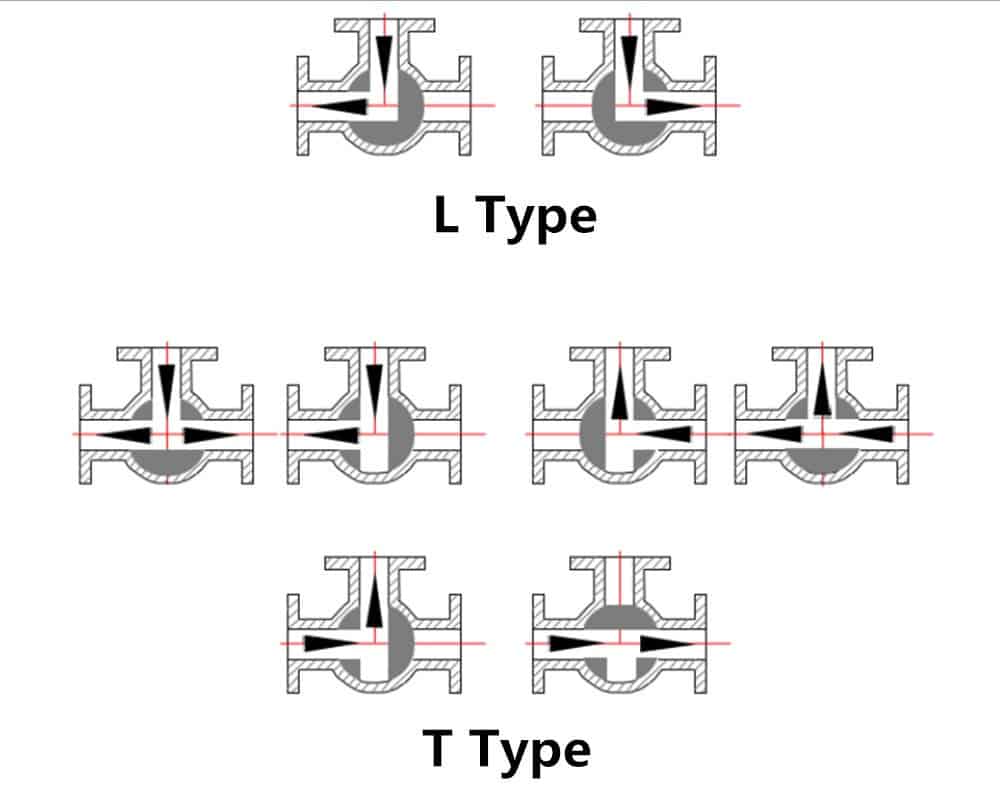

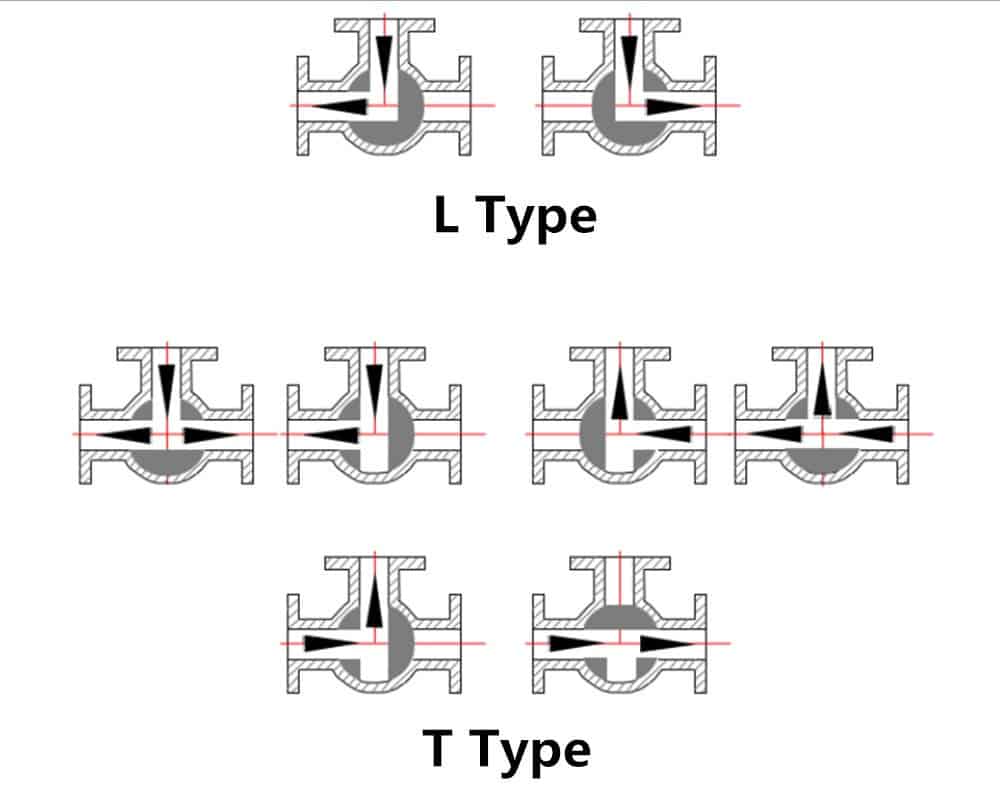

3-way valves are available in two main configurations: T-port and L-port valves. The primary difference between these two types lies in the orientation of the flow paths:

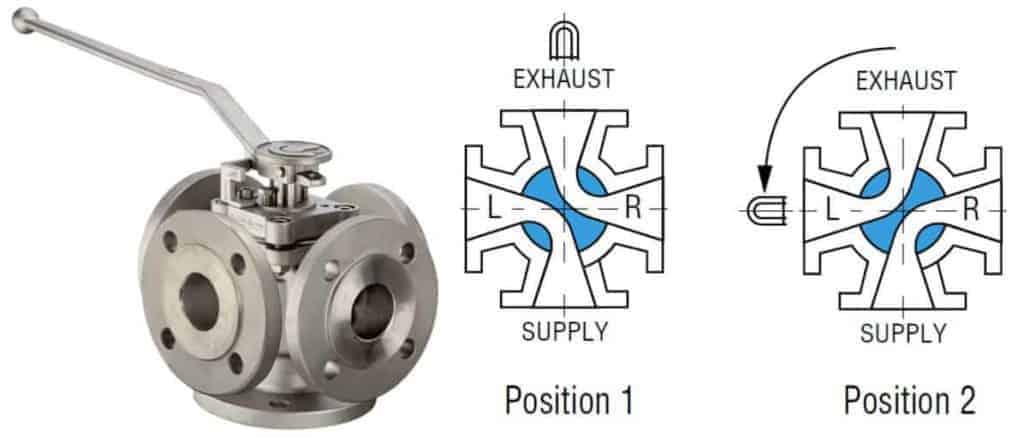

T-Port Valves: In T-port valves, the flow paths are arranged in a T shape, allowing fluid to flow from the common port to both other ports simultaneously. This configuration is ideal for mixing or diverting applications, such as blending hot and cold water in heating systems.

L-Port Valves: L-port valves have an L-shaped flow path, enabling fluid to flow from the common port to only one of the other ports at a time. L-port valves are well-suited for switching between two flow paths or for shut-off applications.

Comparisons with 2-Way Valves

When comparing 3-way valves to 2-way valves, it’s essential to consider their differences in terms of functionality, system complexity, and cost:

Functionality: 2-way valves primarily control the flow of fluid by either fully opening or closing a single flow path, while 3-way valves offer the additional ability to mix, divert, or bypass fluid flows, providing greater versatility.

System Complexity: Using a single 3-way valve can often replace multiple 2-way valves, simplifying the overall system design, reducing the number of components, and minimizing potential leak points.

Cost Considerations: While 3-way valves may have a higher initial cost compared to 2-way valves, the potential savings in system complexity, reduced maintenance, and improved efficiency can often outweigh the initial investment, making them a more cost-effective choice in the long run.

Manual Valve Control

As the name suggests, manual valve control involves an operator’s direct manipulation of the valve handle to open, close, or adjust the fluid flow through the system. Some common types of manual handles include:

- Lever Handles: These are most commonly used with ball, butterfly, and plug valves, providing quick and straightforward operation through a 90-degree turn.

- Handwheels: Typically used with gate, globe, and diaphragm valves, handwheels require multiple rotations to open or close the Valve, allowing for precise flow control.

Advantages of Manual Valve Control:

Lower initial cost compared to automatic control systems

Simple installation and maintenance requirements

Ideal for small systems or infrequent valve operation

- Automatic valve control relies on an actuator, a device that converts energy into motion, to control the Valve’s position without direct human intervention. There are several types of actuators available, including:

- Electric Actuators: These use electric motors to provide precise valve positioning and are suitable for applications requiring remote control or integration with an automation system.

- Pneumatic Actuators: Utilizing compressed air, pneumatic actuators are known for their fast and reliable operation, often used in applications where safety is a top priority.

- Hydraulic Actuators: Hydraulic actuators employ pressurized fluid to control valve movement, providing exceptional force and precise control, making them suitable for heavy-duty applications. Advantages of Automatic Valve Control:

Enhanced precision and repeatability in valve positioning

Remote operation capabilities, ideal for hard-to-reach or hazardous locations

Integration with automation systems for improved efficiency and process control

At Plumberstar, we cater to the diverse needs of our clients by offering a wide range of manual and automatic control options for our customized home valve and pipe fitting products. Whether you require simple manual operation or advanced automatic control for complex systems, our experienced team will work with you to ensure you receive the most suitable solution for your specific application.

In conclusion, 3-way valves offer increased versatility, simplified system design, and improved efficiency compared to 2-way valves.

Why Choose Plumberstar’s 3-Way Valves?

Customization: Our variety of materials, sizes, and pressure ratings ensure a tailored solution for your specific needs.

Quality Assurance: Our 3-way valves undergo rigorous quality control processes, including 100% product pressure testing, guaranteeing the highest performance and durability standards.

Expert Support: Our knowledgeable team is available to provide technical assistance and guidance, ensuring a seamless experience from start to finish.

Competitive Pricing: As a B2B factory-direct supplier, we offer competitive pricing without sacrificing quality.

Personalized Service: We prioritize personalized service and quality assurance, helping us establish long-term partnerships with our clients.

By considering the materials, temperature, pressure ratings, specifications, and applications, you can make an informed decision on the best valve solution for your needs. Choose Plumberstar‘s metal valves for a reliable, high-quality, and customizable valve solution that will exceed your expectations.