One of the DIY plumping activities that can be stress-free with the right knowledge is using compression fittings on copper pipes. Getting the right materials from a good compression fitting and copper pipe manufacturer will go a long way. To better understand how one can do this pumping activity quickly, it is mandatory to understand the components of the compression fittings and the copper pipes. This article will discuss how to use compression fittings on copper pipes easily.

What is a compression fitting?

Simply put, compression fitting is a type of fitting that is used to join two pipes’ edges together. These pipes could be used for plumbing or electrical conduits. Compression fittings are also used when two pipes are made of different materials. This type of fittings can be used where a part of a pipe is difficult to solder.

What is a copper pipe?

A copper pipe is a type of plumbing pipe that transfers fluids. Copper pipes are commonly used for plumbing projects because they are strong, lightweight, and corrosion-resistant.

What will you need?

One must consider some factors to use compression fittings on copper pipes successfully. These factors will determine how efficient the process will be. Before connecting two edges of copper pipes, you must understand how vital these factors are. Thus, breaking down the factors before carrying out any project is advisable. These factors are:

Materials: there will be no result from using compression fittings on copper pipes if no essential materials are readily available. Some essential materials are compression fittings, glue, and copper pipes. To ensure good results, buying the materials from a reputable compression fitting and copper pipe manufacturer like Plumberstar is best. Plumberstar is an award-winning compression fitting and copper pipe manufacturer that sells all kinds of plumbing materials. Buying quality materials will be a plus.

Time: understanding the total duration of the process will go a long way. Depending on how knowledgeable one is, using compression fittings on copper pipes should take 15 minutes or more. Planning before starting the process can reduce the duration by half. The process is a simple connection that should be seamless.

Skills: another factor that can determine how effective the process of using compression fittings on copper pipes will be is skills. Having the right skills for this plumbing process is key. Your level of skill will show in the result. Therefore, getting the necessary skills for the job is important. Researching on how to carry out the process will help.

Tools: the final Factor is “tools.” All plumbing works require different tools. Knowing the right tool for different plumbing projects will solve 70% of the problem. Using compression fittings on copper pipes requires a few tools as well. Pipe holders and pliers are two important tools needed for an excellent result.

How does a compression fitting work?

After purchasing the materials from a reliable compression fitting and copper pipe manufacturer, one needs to understand how a compression fitting works. Before we move forward, we need to explain some parts of the compression fitting. These parts make the compression fitting work efficiently. The parts are;

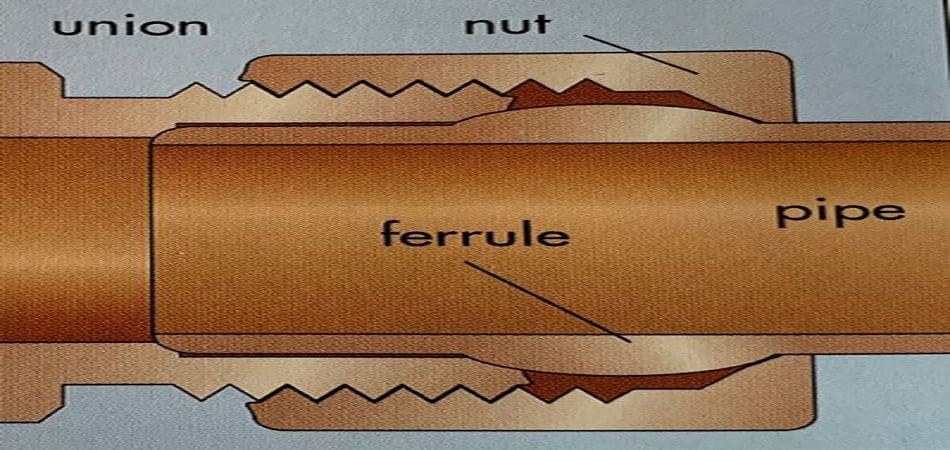

Ferrule: this is the part that strengthens or forms a joint. It is there to ensure the two pipe edges do not wear out. It is a metal ring that prevents pipes from splitting.

Nut: this is a flat piece of metal in the compression fitting. It is a crucial part of the compression fitting that makes it possible to use compression fitting on copper pipes.

The compression fittings function when the nut forms a seal and compresses or squeezes the ferrule against the pipe. Since the copper pipe is soft, it will be tight. To perfect this process, the pipe joint mixture or tape, preferably a Teflon plumber’s tape, should be used to make the seal watertight.

The diagram below shows the side view of a compression fitting.

How to make compression joint

Making a compression joint is the first step to achieving an excellent compression fitting on a copper pipe. There are five basic steps to achieving a good compression joint. These steps help with understanding how easy making a compression joint could be. The basic steps are:

Prepare the tools: the first step is to prepare all the tools needed to make a compression joint. The pipe holder, a plier, and a wrender are three popular tools. Knowing how to use these tools is also important. For a first-timer, watching videos on how to use the tools will help.

Turn off the water: this is the next step towards making a compression joint. Turning off the water before working on any plumbing project is essential. Turning off the water system will make your work easier and possible. To start, turn off the water and turn off the valve.

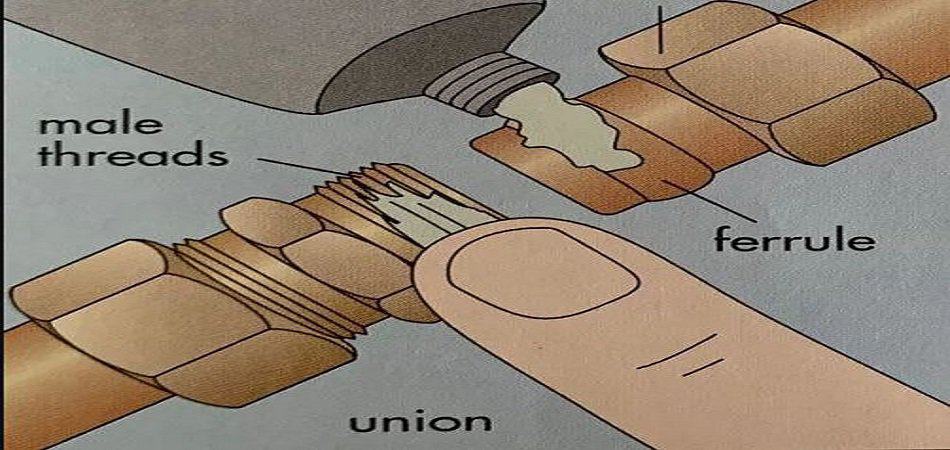

Place the parts: placing all the parts in the right places is the next step. Bending the tubing part into a round and perfect angle is necessary. The ferrule will only function well if the tubing is correctly placed. Adjusting the ferrule on the male threads is important to achieve a great result.

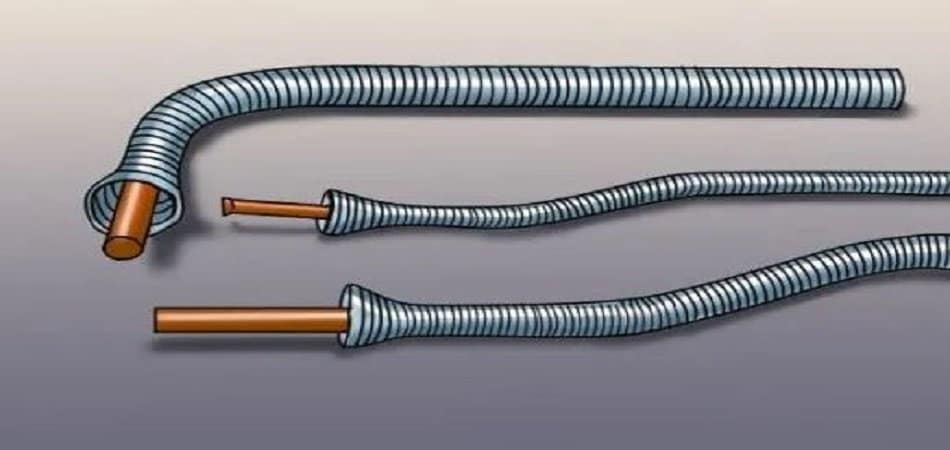

Tubing kinks: allowing the tubing to kink will lead to a problem. You must be careful when bending the pipe to prevent tubing from kinking. Always have it at the back of your mind that once a tubing kinks, it is almost impossible to go back to its previous position. To prevent tubing kinks, use a coil spring tubing bender. The coil tubing bender allows for easy bending of copper and aluminum.

Tightening the nut: to finish the compression joint, you must tighten the nut. The nut is above the ferrule. A wrench is the right tool for tightening the nut. Be gentle on the nut when tightening it. Do not add too much Force because high pressure can break the tubing. Too much Force can also destroy the nut.

How to join a compression union

There may be no need to create a compression joint, especially when making a compression joint is unnecessary. In a situation like this, a compression union may be needed. The following steps will help in making a compression union;

Prepare the materials: The materials needed to make a compression union must be prepared. Getting the right tools and materials at the right time will make the process easy. Tools like a wrench and a plier will work for this process.

Turn off the water: Understandably, it can be annoying to read this particular instruction repeatedly. However, the instruction is very important and cannot be said enough. Water running while you are doing a plumbing job will render the project useless.

Join the parts: there is a need to position the parts at the right angles. This will enhance the joining of the parts together. To prevent water leakage, tighten the ferrule and the male threads properly.

Tighten the sides: To make a compression union, you need to tighten the ferrule and the sides of the male thread with your hand. Finish the process by tightening the two sides with a wrench.

Frequently Asked Questions

- Are compression fittings reliable?

Generally, the compression fittings are reliable compared to other threaded fittings.

- How easy is compression fitting?

It is very easy to install. The duration is around 15 minutes with the right skills.

- Can I remove a compression fitting?

It is almost impossible. It is best to cut it off.

- Does compression fitting prevent water leakage?

Yes! It prevents water leakage if done the right way.

- Where can I buy the materials?

There are a lot of manufacturers around; however, getting a reliable compression fitting and copper pipe manufacturer can be tedious. Plumberstar is where you can get various plumbing materials like brass valves, angle valves, cast iron valves etc.