Description

Solenoid Valves

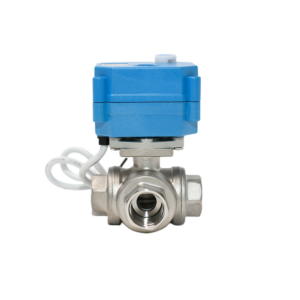

JX-0327

The temperature of the Media: Medium Temperature

Power: Solenoid

Media: Water

Port Size:1/2″-1″

Structure: BALL

Rotate angle:90°

Working pressure:≤1.6Mpa

Medium temperature:

-10℃~125℃

Valve material: BRASS

Thread end: ISO228

IP class: Ip56

SIZE; DN15、 DN20、 DN25

ITEM(2 WAY OR 3 WAY)

Voltage;AC220V,AC110V,AC24V,DC24V

Current,0.04A,0.08A,0.3A,0.05A

Watts,8W,8W,7W,1.5W

Torque,5Nm,5Nm,5Nm,5Nm

Switching time,12s/24s,12s,12s,15s

Rotate angle,90°

3 Way Solenoid Valves

Solenoid valves are an important component of industrial automation and control systems. They allow precise control over the flow of liquids, gases, and other media by using electric current to open or close valves. Shut-off 3-way solenoid valves are a specific type of valve with three ports, allowing them to be used in various applications. These valves can be utilized in various industries, from food processing to automotive engineering.

Shut-off 3-way solenoid valves offer several advantages over other solenoid valve designs. They can provide higher flow rates than single-way and two-way designs due to their larger port sizes; they also have fewer connections, reducing the risk of leakage and increasing overall efficiency.

Types of 3-Way Valves

A 3-way solenoid valve is a type of shut-off valve that can be used in many different applications. These valves are designed to open or close when electrical power is applied. They come in several types, each specifically suited for different requirements. Understanding the differences between the types can help you determine which one is right for your needs.

The two main categories of 3-way solenoid valves are normally closed and normally open. A normally closed valve has an internal spring that keeps it closed until electrical power is applied, while a normally open valve remains open until power is applied to close it. Both these types have additional variations, such as 2-position and multi-position valves, which provide more control over water flow and pressure regulation.

Benefits of Shut-off Solenoid Valves

Shut-off solenoid valves are an essential piece of equipment for factories and industrial plants, as they provide a range of benefits. These valves allow operators to control the flow of liquids and gases within their systems, providing reliable performance and improved safety. With a shut-off solenoid valve, operators can easily automate the process of shutting off these flows when needed. This provides an easy way to ensure that potentially hazardous liquid or gas spills are contained for quick cleanup after malfunctions or other events. In addition, shut-off solenoid valves offer superior accuracy compared to manual operations, allowing operators to regulate flows more precisely without sacrificing performance.

The reliability offered by shut-off solenoid valves also helps reduce downtime caused by unexpected events or extreme conditions.

Installation and Maintenance

Installation and maintenance of a shut-off 3-way solenoid valve can ensure reliable and safe operation. The process begins with installing the valve body in a pipe or tubing line. It is important to ensure that the proper size and type of fittings are used and the correct sealing methods so that no leakage occurs at connection points. The next step is to mount the solenoid valve onto the valve body. This should be done carefully to ensure full contact between all components for better performance and longer life. Finally, it is important to regularly inspect the valve for any wear or damage that could affect its performance or lead to potential failure. Regular preventative maintenance, such as lubricating moving parts and replacing seals, will help keep your shut-off 3-way solenoid valves functioning properly for many years.

Troubleshooting Tips

Troubleshooting tips can often be the difference between a successful repair and hours of frustration. When it comes to shut-off three-way solenoid valves, a few key steps should be followed when attempting to troubleshoot any issues. Firstly, it is important to check the voltage supply as this will determine whether or not the valve is receiving power. Secondly, ensure that all tubing and wires are connected properly and securely. Lastly, inspect for any signs of corrosion or damage that could impede the system’s performance. With these simple but effective steps in mind, you’ll be able to quickly identify and fix any problems you may experience with your shut-off three-way solenoid valves.

Replacement Considerations

Replacement Considerations for Shut-off 3-Way Solenoid Valves

When considering the need to replace a shut-off 3-way solenoid valve, it’s important to understand the features and benefits of these valves. Shut-off 3-way solenoid valves are used in many applications to regulate the flow of liquids and gases. These valves can be used as shut-off devices or to change the direction of fluid flow. They are also designed for easy maintenance, with simple installation procedures that require minimal effort.

When choosing a replacement valve, there are many factors to consider, including size, pressure rating, materials compatibility, maximum operating temperature, power requirements, response time, and voltage ratings. It is also important to choose a valve from a reputable supplier that offers reliable customer service and access to technical support staff.

How Do Solenoid Valves Work?

This valve is a three-way ball valve with automatic pressure release, which can be used to control water flow and temperature. It has an actuator that controls the opening and closing of the flow path. The solenoid 3-way electric actuator ball valve is designed for high-pressure applications, such as water supply or hydraulic systems.

The 20V-110V, 24V 3-way electric actuator ball valve is a versatile and reliable solution for controlling water flow. This valve can be operated either manually or by an external power source. The solenoid is powered with 110 volts and has a solid air-tight seal to keep the fluid locked in the system. It also features a convenient built-in safety feature that will shut off both power inputs before any damage can occur if something goes wrong with your setup. This product comes as shown, ready to install and use!

Solenoid 3-way electric actuator ball valve for 20v, 110v 24v.

A self-contained, automatic pilot-operated solenoid-actuated three-way electric actuator ball valve designed to control the flow of liquids and gases in a system. It has an integral magnetic latching mechanism that locks the plunger in its seated position when power is removed from the coil. The actuator is available with many combinations of voltage ratings and stroke lengths.

The product can be supplied with various materials, including steel, stainless steel, bronze, or hard rubber seals depending on operating conditions such as temperature range and pressure rating requirements.

It comes in standard configurations with threaded connections -1/2″ BSP, NPT,3/4in, and 1in

An actuator ball valve is a control valve that uses an electric motor to move a plunger, or “actuator,” which opens and closes the valve. This allows for fast opening and closing times and high flow rates. A solenoid 3-way electric actuator ball valve is typically used in industrial settings when different pressures are on either side of the chest wall. Turning off the supply from one side must first be isolated by turning off the other side with a shut-off device like this one. These valves are commonly found in water treatment plants where they can isolate feed lines coming into storage tanks during maintenance periods.

Close-off: 350 psi (24.82 bar) non-shock cold working pressure.

Max: 50 psi (3.45 bar) for typical applications.

The valves hold a long service life that ensures the fixing is appropriate for the duration expected for the valve’s life. It is important to note that these aspects are applicable even if the valve is not used for a given period increasing the reliability and durability of the valves.