Description

OEM Male Y-Strainer

JX-0609

- Brass Y Strainer

- Pressure rated to 30 bar

- Forged brass with nickel-plated

- Media; Water, Air

- Thread connection: G, BSP

- Suitable for domestic water services, heating and air-conditioning plants, and compressed air systems.

- Female/female threads and inspection plug.

- Body in nickel-plated brass.

- Minimum and maximum working temperatures: -20°C, 110°C without steam.

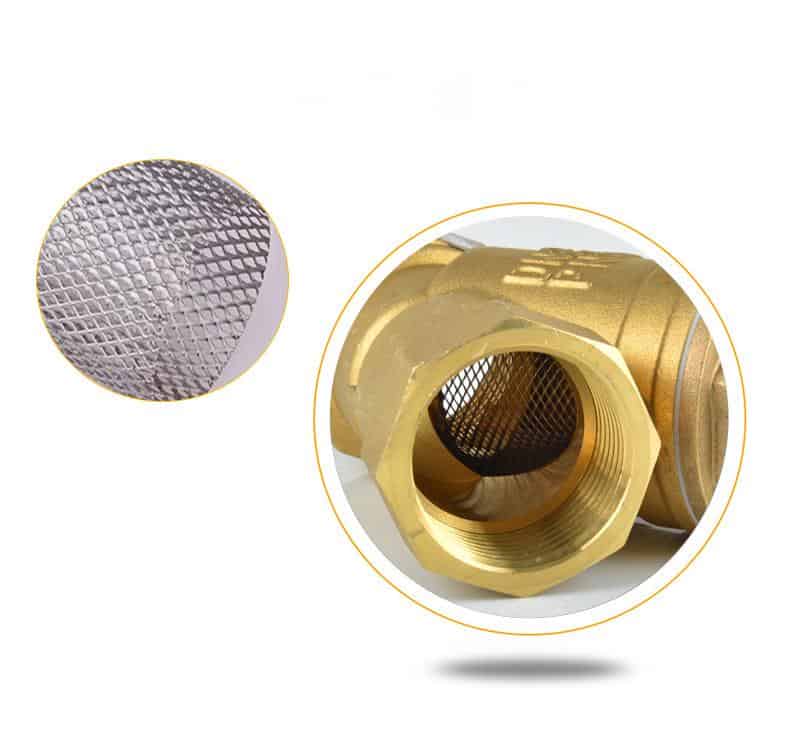

- Available in 3 filtration degrees: 500µm, 300µm, and 50µm.

- Threads ISO228 (equivalent to DIN EN ISO 228 and BS EN ISO 228).

Brass Y-strainer

A brass Y strainer is a type of kitchen tool with a “Y” shape, with one straight leg and one curved leg. This design allows liquid to flow through while larger solids are filtered out. Brass is used because it does not corrode or react with food like other metals might, but if you’re looking for an alternative material, stainless steel versions are available too! They’re typically used in restaurants or commercial kitchens but can also be handy for the home cook. You can find them at most kitchen stores or online.

Some typical applications for a brass Y strainer are:

-Draining pasta

-Straining soup or broth

-Draining rice

-Strainer for jams and jellies

This tool has a long handle with holes at the end, allowing liquid to drain while trapping solids inside. The strainer is typically cone-shaped, but some versions look like flat disks or small bowls on top of pots and pans. Stainless steel is also available if you’re looking for an alternative material option! They’re used in restaurants or commercial kitchens but can also be handy for the home cook. Brass Y strainers usually have two legs: one straight leg and one curved leg, so liquids flow easily while larger solids stay behind to be filtered away from the food. Applications include draining pasta, soups and broths, rice, hot jams, and jellies.

Applications of brass Y-strainer are in various drainage systems, potable water systems, process systems, and irrigation systems. It is also used in air-conditioning and, your last will, refrigeration plants, automotive service shops, food and beverage plants, and many m to now.

Brass Y-Strainer valve

A Brass Y-Strainer valve is ideal for industrial, commercial, and residential applications requiring strainers to protect valves and other delicate components from dirt, scale, rust particles, and other debris. This brass strainer is designed for high flow capacity with minimum pressure drop. It has a wide range of orifice sizes, ranging from 1/4 inch to 4 inches. The body is made from Forged Brass ASTM C37700 for maximum strength and corrosion resistance, while the screen is an integral part of the strainer body, ensuring maximum durability in all types of environments.

The Y-strainer features a compact design that can be installed in tight spaces without compromising performance or reliability. The removable strainer basket allows easy access to remove collected debris without disassembling the unit.

Benefits of using a Brass Y- Strainer Valve

Brass Y-Strainer valves are a valuable asset in the plumbing or piping industry. These specialized pipes serve an important function in the water system, filtering out any debris that might be caught in the line before it reaches its destination. Because of their small size and durable construction, they can be used in residential and commercial applications to help keep pipelines clean. Here are some of the main benefits associated with using a Brass Y-Strainer valve:

First, Brass Y-Strainer valves are incredibly reliable. They’re made from a robust material that can withstand high temperatures without breaking down or corroding. Additionally, these valves come equipped with an internal filter screen that captures unwanted particles, such as sand or silt, before entering the pipeline system.

How to Install a Brass Y-Strainer Valve

Installing a brass Y-strainer valve is a great way to protect the plumbing system in your home from debris and dirt. Made from strong, durable metal, these valves can help keep unwanted particles out of water lines and prevent damage to pipes and fixtures. Installing one correctly is not that difficult, but it does require some basic knowledge of plumbing tools and techniques. Here are a few steps you should follow when installing your brass Y-strainer valve.

Begin by turning off the water line leading into the strainer valve; then unscrew and remove the existing shutoff valve or pipe cap connected to the Y-strainer opening. Next, clean any rust or debris around the opening before attaching the new strainer with two nuts onto either side of its body.

Common Problems with Brass Y-Strainer Valves

The use of brass Y-strainer valves is a popular choice for many industrial and commercial applications. These valves protect piping systems from dirt, debris, and other particles that can cause damage or otherwise interfere with the system’s operation. However, some common problems associated with these valves should be monitored closely.

One of the most common issues with brass Y-strainer valves is clogging. These valves work best when they are kept clean and free from blockages, as any buildup in the valve can reduce its effectiveness and lead to other problems, such as increased back pressure or reduced flow rate. Regular maintenance is important to prevent clogging and ensure proper valve operation over time.

Another potential issue is corrosion caused by exposure to water or chemicals in process fluids or environmental conditions like temperature changes.