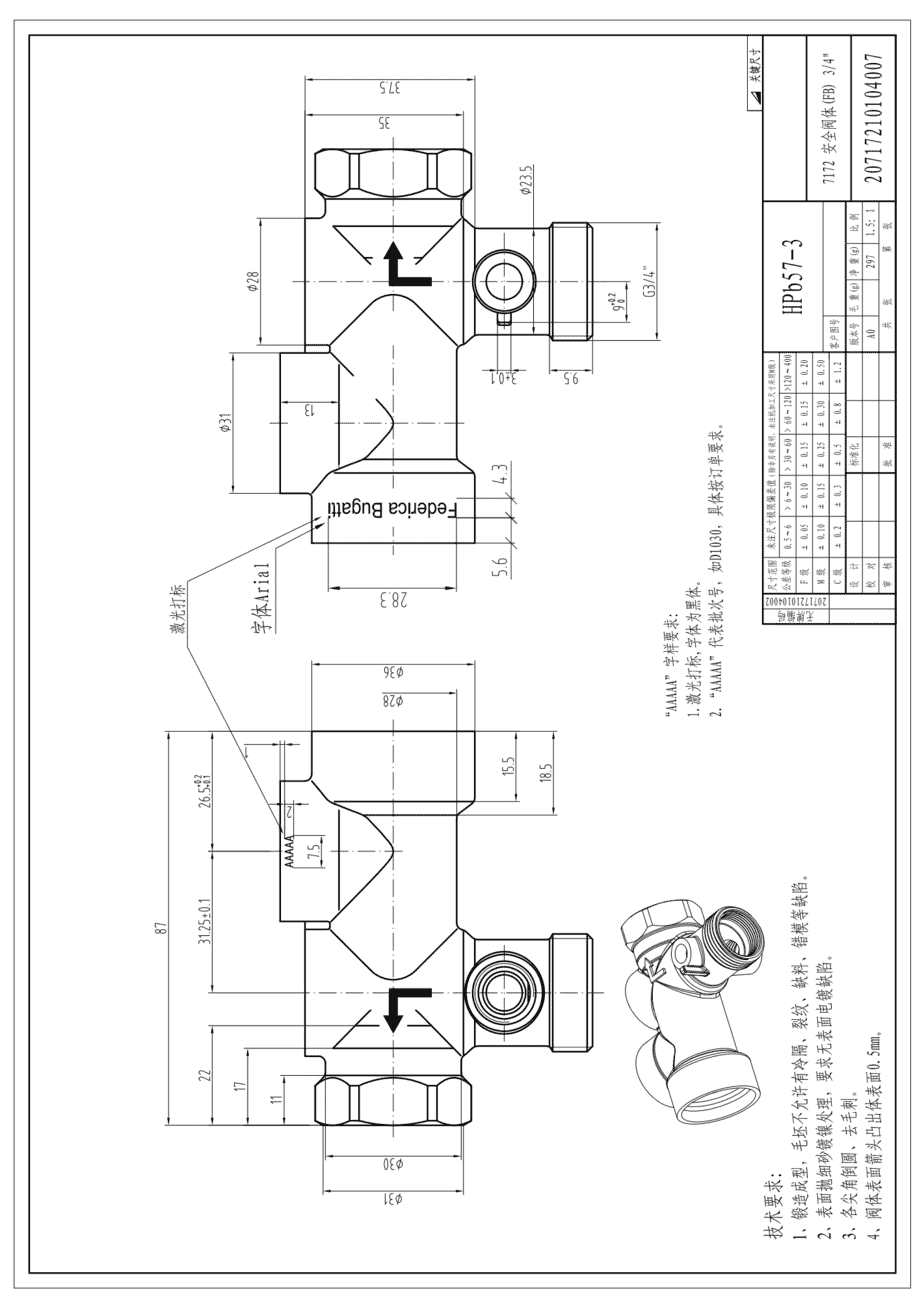

Description

Adjustable Water Pressure Regulator

JX-0910

Sandblasted with nickel plated

The working medium is water

Max working pressure is 10 bar

The working temperature is 0℃-110℃

The pressure for relief is 0.7Mpa

Simple internal structure, fine craft.

Apply to Hydraulic instability, water flow too fast, water purifiers, solar energy, gas heater, and faucet.

The valve working principle can be understood as the entrance pressure and outlet pressure = spring force, through the control valve closure flow inside the opening of the size to control the pressure at the outlet, the water through the opening, closure and fluid resistance is small, the pressure loss is slight, the outlet pressure is more tremendous, and vice versa outlet pressure is acceptable.

- The pressure-reducing valve adopts a piston structure, and the internal system is simple. The nut can be rotated through the movable joint, and only the sealing gasket can be placed to complete the installation.

- This water pressure-reducing valve does not require a bypass pipe, and the distribution pipe is simple, saving a lot of space and distribution costs.

- The water pressure relief valve has a pressure adjustment knob inside the top cover, adjusted freely. It is equipped with a pressure gauge for easy viewing of pressure.

- The water pressure relief valve can withstand a pressure of 1.6 MPa and can be installed in front of most tap water equipment to regulate water pressure.

- We strive to provide you with the highest quality product and customer experience. If you’re not entirely satisfied, please get in touch with us at any time.

A suitable water pressure regulator is essential for your home or business. You want to ensure that you get the right amount of pressure, usually between 40 and 60 psi. Too much stress can cause problems with your pipes. While too little will lead to clogs in your lines, adjustable water pressure regulators are important for optimizing flow rates and preventing pipe damage!

Most homes and businesses have water pressure that is too high. This can cause many problems, including pipe damage, leaks, and even explosions! That’s why it’s so important to have an adjustable water pressure regulator installed in your plumbing system. A flexible water pressure regulator will allow you to adjust the pressure that comes through your pipes, ensuring that you always have the right amount for your needs. Not only does this protect your plumbing system, but it also helps to conserve energy by preventing excessive flow rates!

If you’re looking for the best way to protect your home or business from high water pressure, then be sure to invest in an adjustable water pressure regulator! These regulators are easy to install and use and can be adjusted to meet the specific needs of your plumbing system. So, if you’re looking for a way to optimize your water flow and protect your pipes, an adjustable water pressure regulator is the perfect solution!

Water Pressure Safety Valve Water pressure safety valves are an essential piece of equipment that help protect homes and businesses from potential water damage caused by excessively high water pressure. Without them, the stress on pipes and fittings can be too much, and they can burst, resulting in huge repair bills or worse. Installing a water pressure safety valve is a simple yet highly effective way to prevent such catastrophes.

How it works, and why one should be installed in any home or business that uses running water. First, we’ll look at the definition of hydraulic safety valves – these devices limit the pressure entering a building’s plumbing system. When the predetermined maximum level is reached, the valve will automatically stop more pressure from entering; this prevents sudden surges, which could cause catastrophic damage.

Definition: What is a Hydraulic Safety Valve? A hydraulic safety valve is a device used to regulate and control water pressure in a system. It has an adjustable relief valve to open when the pressure reaches a predetermined level. The primary purpose of this device is to protect equipment from damage due to excessive pressure or temperature changes.

The safety valve works by discharging pressurized fluid when the specified limit has been reached, allowing for the safe release of excess energy and preventing any potential damages caused by the sudden increase in pressure. In addition, these valves are designed with an internal mechanism that allows for automatic resetting after it has opened. This ensures that any future increases in pressure will be properly monitored and regulated, making it possible to avoid costly repairs or replacements down the line.

Operation: How Does it Function? Operation: How Does it Function?

When it comes to water-pressure hydraulic safety valves, the operation is key. This type of valve ensures that the pressure in a water system does not exceed an unsafe level and that any sudden pressure surges are quickly reduced.

The main function of a water-pressure hydraulic safety valve is to reduce fluid pressure when it rises above a certain level. It allows fluid to flow back out of the system if its internal pressure reaches an unsafe level or if there is a sudden surge in that pressure. This helps protect people and equipment from potential harm caused by excessive high-pressure levels. The valve also maintains an accurate operating temperature range while providing reliable protection against overpressure conditions.

Installation:

Installing the Valve Installing the Valve is an important step in maintaining your Water Pressure Hydraulic Safety Valve. Ensuring your safety valve is correctly installed and working properly can help prevent water damage to property and potential injury from flooding. Understanding the installation process before beginning is important, as incorrect installation can lead to serious consequences.

The first step in installing the valve is determining its placement of it. This will depend on your specific needs, but it should generally be located after a pressure relief valve and before any hose outlets, such as faucets or showers. Once you have determined the location of your safety valve, you can begin attaching it to the plumbing system using appropriate fittings for whatever size pipe you are using. When connecting pipes with threads, ensure they are secured with thread tape or pipe dope before being tightened down into place.

Maintenance:

Caring for the System Having a well-maintained water system is essential for any home or business. A hydraulic safety valve ensures that water pressure in the system remains at safe levels. Not only can high pressure cause extensive damage to pipes and fixtures–it can even lead to more serious health hazards. Regular maintenance of this important system component is necessary for optimal safety and performance.

The hydraulic safety valve restricts water flow within the line according to predetermined specifications; it automatically adjusts depending on pressure levels. It should be inspected regularly to ensure its components are working properly and that all connections are secure. If there’s an issue, contact a licensed professional right away; they will be able to diagnose and fix any potential problems quickly and efficiently before they become worse or more expensive over time.

Common Problems & Solutions

Water-pressure hydraulic safety valves are vital to many different industrial and commercial systems. Keeping these hydraulic valves functioning properly is essential for the overall operation of the system. Unfortunately, common problems may lead to a malfunctioning safety valve or even total system failure. Here, we will discuss some of the most common issues and their solutions to keep your water pressure hydraulic safety valve performing safely and effectively.

The most frequent issue with these valves is severe clogging due to dirt, debris, or other contaminants in the water supply. This often results in an inadequate flow rate through the safety valve, leading to overall performance degradation over time.

Conclusion Water pressure hydraulic safety valves are essential to any machinery or equipment that uses pressurized water. Without them, the system is at risk of malfunction and potential danger to people and property.

Water pressure hydraulic safety valves are important in maintaining the efficiency of systems utilizing pressurized water and providing a vital safeguard against accidents due to unregulated pressures. They are relatively simple mechanisms that can be easily inspected and maintained to ensure they remain operational for many years with minimal cost or effort. Ultimately, investing in such a valve can save money on repairs later down the line – not to mention reducing the likelihood of catastrophic damage from unchecked pressure build-up.