Description

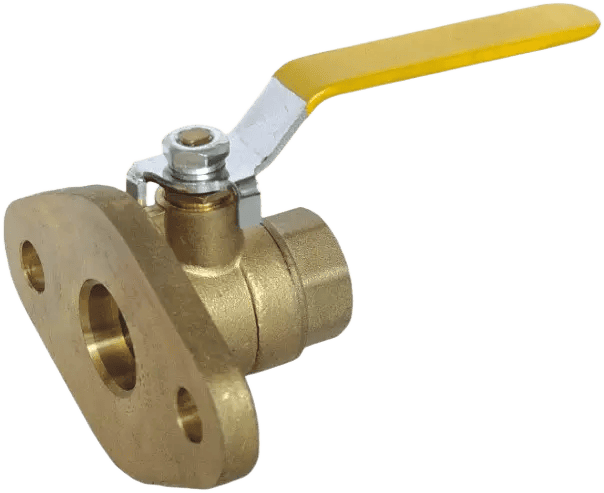

High-Performance Brass Flange Ball Valve

JX-0417

- CuZn39Pb3, CZ121, C37710, CW614N, CW617N, DZR

- 1/2″-2″

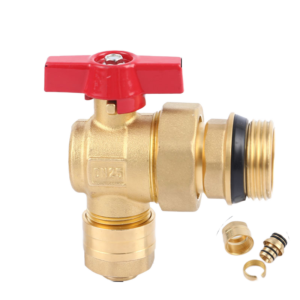

High-Performance Brass Ball Valve

A high-performance brass flange ball valve is essential for any industrial operation. It regulates the flow of liquids, gases, and other substances through pipes or valves. This type of valve offers superior performance compared to other materials due to its construction and materials used.

The primary benefit of the brass flange ball valve is its ability to withstand high pressure and temperature conditions without compromising performance. The material used in these valves is a combination of brass, bronze, steel, and other alloys designed for maximum durability in extreme environments. Additionally, their sealing capability ensures no leakage occurs when using this type of valve. Furthermore, they are resistant to corrosion, making them ideal for use in corrosive environments and areas prone to fluctuating temperatures or pressures.

Design Characteristics

Design Characteristics of High-Performance Brass Flange Ball Valve

High-performance brass flange ball valves are becoming increasingly popular in industrial settings due to their superior performance characteristics. These valves feature tight shutoff and leak-tight sealing, allowing for precise flow control and dependable operation. Additionally, these valves offer excellent corrosion resistance and long service life due to the use of high-quality materials. The valve design also features an adjustable packing gland which provides a reliable seal even in fluctuating temperatures and pressures. Furthermore, these valves are available in various sizes ranging from 1/2-inch to 2-inch diameters and different end connections such as socket weld, threaded or flanged ends for easy installation.

Uses of High-Performance Valves

High-performance brass flange ball valves have become increasingly important in various industrial settings. With the ability to control pressure and flow, these valves offer several advantages that can be used in many applications. From controlling water and oil pipelines to regulating fuel systems, high-performance brass flange ball valves are incredibly versatile and reliable components.

The key advantage these valves possess is their durability. Their solid body construction ensures they will not corrode or suffer from wear and tear over time, as many other valves do. In addition, they provide tight shutoff capabilities, which can be adjusted quickly and easily to maintain precise pressure control. These features make them an ideal option for industrial operations involving liquids or gases that require quick response times during operation or regular maintenance checks, such as boilers or heating systems.

Benefits of a Brass Flange Valve

A brass flange valve is a high-performance ball valve that offers several advantages over traditional valves. The use of brass material provides superior corrosion resistance, making it an ideal choice for several industrial applications. Furthermore, brass flange valves are known for their long service life and durability, making them an excellent choice for long-term process control and maintenance. Additionally, these valves provide excellent flow characteristics due to their low friction coefficient and free flow area design, making them suitable for most liquids and gases.

Brass flange valves can offer a cost-effective solution compared to other metals, as they require minimal maintenance and are easy to install in existing systems. These valves can operate at high pressures without excessive wear or fatigue, allowing them to be used in demanding applications where precision control is needed.

Installation Considerations

When searching for the right valve for a system, it is important to consider installation considerations. High-performance brass flange ball valves are an ideal choice for systems that require quick, reliable operation and a secure connection. These valves offer strength and reliability under pressure, but proper installation is essential to ensure that the valve is functional and safe.

Before installing any high-performance brass flange ball valve, users must assess their requirements to determine the best size and type of valve for their application. The line size should be considered when selecting a flanged ball valve and its material composition. Installation considerations, such as whether or not additional support will be required, must also be determined before installation begins.

Maintenance & Troubleshooting

High-performance brass flange ball valves are essential for various industrial and commercial applications. Such valves are designed to provide years of reliable operation, but proper maintenance and troubleshooting techniques must be used to ensure optimal performance. Maintaining and troubleshooting these valves properly is essential for avoiding costly repairs or replacements down the line.

Proper maintenance of high-performance brass flange ball valves begins with an inspection before installation. This will help ensure that the valve is suitable for its intended application and identify any potential areas of concern that need attention before operating the valve. Additionally, periodic inspections should be done during operation to look for signs of wear or damage that may need to be addressed. Regular cleaning and lubrication can also extend the lifespan of these valves and keep them running smoothly over time.

Conclusion: Quality Control and Performance

Quality control ensures that any incoming components are up to standard and that any valves produced to meet the appropriate standards. Performance is also vital, as it will determine how well the valve can withstand certain conditions and pressures, ultimately determining its lifespan. To ensure quality control and performance are met, manufacturers should seek certified parts from trusted suppliers with an established track record for producing reliable valves. They should also consider testing each unit before shipment to detect potential issues before delivery. Finally, by partnering with a qualified manufacturer with extensive experience in quality control and performance measures, end users can rest assured knowing their valves will perform safely for years to come.