The refrigerant sight glass component is straightforward. It only shows if the liquid line fills with or contains bubbles. If bubbles are present, a liquid/vapor mixture is present.

An operating system’s clear sight glass indicates a full line of liquid. Reading sub-cooling only establishes that the system has a full line of liquid. Although, which is what a sight glass accomplishes. Subcooling in HVAC provides more information than full-sight glass. The process of sub-cooling reveals how much actual heat refrigerant is lost. As far as after reaching the condensing temperature. Sight glasses can tell you if a liquid column is entire, but it is the only information they provide.

A sight glass is an excellent tool for refrigeration systems with receivers. Yet, we can rely on it to show the presence of liquid refrigerant at the metering device.

So the Refrigerant Sight Glass, as the name suggests, is a clear, transparent window installed in the liquid line of refrigeration systems. It allows technicians to visibly monitor the flow and condition of refrigerants, helping them ensure the system is charged accurately and runs efficiently.

Why is Refrigerant Sight Glass Important?

Efficiency and Safety are two pillars of any mechanical or hardware operation, especially in businesses like Plumberstar, where the priority lies in delivering high-quality, customizable products. A refrigerant sight glass plays a pivotal role in both these aspects.

Why Does Refrigerant Flow Matter?

A refrigeration system’s efficiency largely depends on the proper flow and charge of the refrigerant. An undercharged or overcharged system runs inefficiently and can lead to long-term damages and increased operational costs. According to data sources, improper refrigerant charge can decrease system efficiency by up to 20%.

Working of sight glass in refrigeration

This part offers a visual means to tell whether the refrigerant is liquid or saturated as it moves through the system while operating. When the refrigerant is liquefied, it is subcooled, and bubbles are not visible. The presence of bubbles indicates that the refrigerant is saturated. Yet, the liquid line sight can be observed until the bubbles are gone. The sight glass turns clear after the automatic pump down begins, and the solenoid closes. This indicates that nothing else is present at the site of the sight glass.

Some eyeglasses change color to indicate the presence of acid in the line. Place the sight glass before the TXV but after the filter drier and solenoid. If a restriction in the liquid line, such as a blocked filter, is present, it can be seen through the sight glass.

Regardless of whether the liquid entering the filter drier is subcooled, this would appear as bubbles in the sight glass. By looking through the sight glass, it is also possible to tell if the solenoid is open or closed. Refrigerant bubbles will still be seen at the solenoid during operation if it is supposed to be closed but is only partially sealed.

Sight glasses function

The sight glass’s duties include monitoring the liquid refrigerant level. However, looking for moisture in the system’s dry filter’s back end. A sight fit in the fluid stream right after the filter drier in systems with expansion valves. The sight glass can work on the discharge line at any desired place. But it’s especially wise to put the sight glass close to the expansion valve. But putting the sight glass close to the expansion valve is especially wise.

The sight glass’s color indicator displays the moisture content.

Green: The refrigerant doesn’t include any hazardous water vapor.

Yellow: The liquid line at the front end of the expansion valve has too much water vapor.

If you notice a bubble in the mirror, the following circumstances are actual:

The dry filter’s excessive pressure drop could be due to obstruction.

Undercooling is not enough. In the system, the total amount of refrigerant is insufficient.

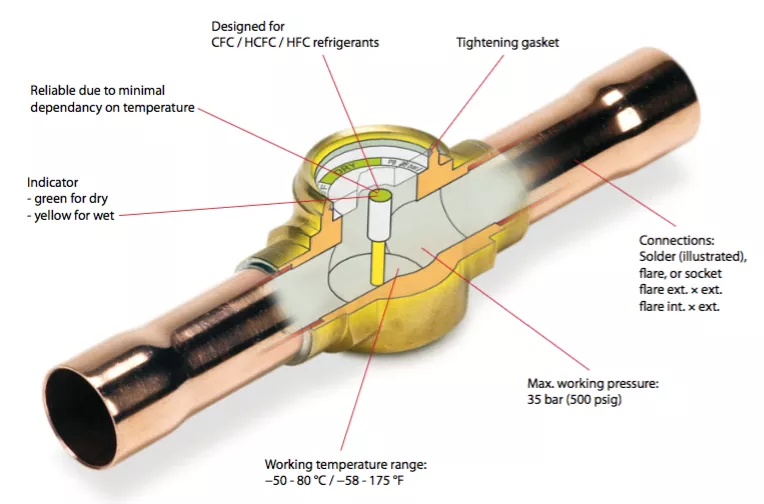

Main Features;

- Indicates cooling system moisture, subcooling, and refrigerant volume shortage

- Compatible with different refrigerants, including CFC, HCFC and HFC

- Wide angle viewing high visibility window for ease of monitoring

- Select interchangeable paper and don’t need disassembly from the pipe.

- Working Temperature Range: -40°C ~ 100°C

- Maximum Working Pressure: 5.0MPa

- The main media is R135a, R404a,R407c,R410a,R507c

Specifications:

| Material | Copper, Steel or Stainless Steel |

| Nominal Size | 1/4“,3/8”,1/2,5/8,3/4″,7/8″ |

| Max Working Pressure | 4.2Mpa-5.0Mpa |

| Temperature Range for Standard Valves | -40°C ~ 100°C |

| Temperature Range for HT Valve Series | -10°C to +200°C |

| Connections | Welding ends as per DIN and ANSI, threaded ends |

Refrigerant Sight Glass: Threaded vs. Silver Soldered 2 Type Connections

The Refrigerant Sight Glass plays a pivotal role in monitoring refrigerant levels in HVAC systems. This simple yet crucial component offers a clear window to gauge the state of the refrigerant—whether it’s in a liquid or gaseous form. But how do you choose the right connection for your Sight Glass?

Threaded Connections in Sight Glasses: Simplicity in Design

Threaded connections remain a steadfast choice for many when connecting sight glasses in refrigeration systems. Let’s break down the essentials:

- Basics: Threads—precise spiral ridges cut into the end of sight glasses and their mounting points—allow these components to be seamlessly screwed together.

- Advantages:

- Ease of Installation: Screw in or unscrew to install or replace.

- Flexibility: Ideal for scenarios requiring frequent inspection or maintenance.

- Sealing: Properly threaded connections, especially with appropriate sealing compounds, ensure a leak-proof viewing point.

- Challenges:

- Possible Misalignment: This is especially true for larger sight glasses or in tight spaces.

- Wear and Tear: Threads may wear out over time, especially with frequent adjustments.

Silver Soldered Connections: A Permanent Watch Window

Silver soldered connections might be the answer for those looking for a more permanent solution. Here’s a closer look:

- Basics: This method involves using a silver alloy as a filler material to bond the sight glass to its attachment point.

- Advantages:

- Strength and Durability: Once soldered, the connection can last the lifetime of the system.

- Clean Finish: Offers a neat appearance, devoid of external threads or fixtures.

- Consistency: Ensures the sight glass remains steady, making it easier to monitor the refrigerant state.

- Challenges:

- Skill Requirement: The soldering process requires a deft touch and proper technique.

- Permanent: Unlike threaded connections, making adjustments or replacements isn’t straightforward.

Deciding Between the Two

Here are some pointers to consider when choosing the connection type for your Refrigerant Sight Glass:

- Application Duration: Threaded connections might be preferable for short-term or frequently changing systems. For long-lasting setups, consider silver soldering.

- Ease vs. Permanence: If you value ease of installation and flexibility, go threaded. For a more permanent and sturdy connection, silver soldering is the answer.

- Installation Expertise: While threading is more straightforward, silver soldering demands more expertise. Ensure you have the right skill set, or seek professional help.

Whether you opt for a threaded or silver soldered connection for your Refrigerant Sight Glass largely depends on your specific requirements and the long-term goals of your refrigeration system. Both methods offer distinct advantages, so consider the needs of your setup and make an informed choice.

Applications of sight glass in refrigeration

In refrigeration systems, liquid line sight glasses can fool non-technical individuals. They are inaccurate and display the amount of refrigerant in the system. They can deceive by showing bubbles at various points. While during the cycle, the system still has plenty of gas.

While the sight glass can show the system full of gas, it may have other problems that mimic a gas shortage. They will display bubbles in the liquid gas if the system is low on gas. Throughout the system’s lifespan, the gas should never need to change.

How Does Sight Glass Aid in System Monitoring?

By simply observing the sight glass, technicians can determine if:

- The system has the right amount of refrigerant.

- There’s any presence of bubbles or foreign particles, which could indicate issues like refrigerant leaks or contamination.

The sight glass indicates the following.

When charging refrigerant, you must ensure all bubbles have burst. The liquid lock position is that. Bubbles are a sign that no condensable gas is present. When the system is not vacuumed, this occurs.

The presence of bubbles indicates the presence of a system leak.

The other condition shows whether the system is dry or wet on the sight glass. It must always be in a dry state. The moisture in the system displays a damp condition, which must dry out before the gas charges.

Location

The refrigerant sight glass is often placed wherever there is liquid flow. The technician can be sure that a solid column of liquid is getting to the expansion device as if it fixes right before it. It can aid in troubleshooting when mounted at the condensing unit.

Styles of Refrigerant Sight Glass

There are two primary types of sight glasses: simple and with a moisture indicator. The refrigerant is seen as it travels down the line using the plain sight window. The system’s moisture content can be determined using sight glass with a moisture indicator. It contains a tiny component that changes color in the presence of moisture.

You can identify system flaws using the information displayed in the sight glass. It advises that you do not rely on the sight glass for diagnosis. Also, avoid diagnosing R134a systems using the sight glass.

One of three possibilities could be true if the sight glass is clear. Either the system is empty, complete, or overloaded. If there is foam, the charge is low, yet if there are only a few bubbles, everything will be fine. It’s usual to see a few bubbles as the compressor starts up when oil streaks are in the sight glass. Since the charge is likely low and the compressor is pumping oil from its sump. The desiccant bag has burst if the sight glass is foggy. However, an R134a system has a sight glass. But, using it or attempting to diagnose the system is not recommended. Consequently, bubbles are common in this setup.

Routine inspection:

Depending on the end user’s operational practices. Yet the interval between sight glass examinations may vary. Yet, plants follow a standard pattern whereby each sight glass is examined once a month. To do this, isolate the sight glass and empty the gauge. Then, review the glass under a flashlight for clear reflections as it would show a chip or crack.

Depending on the sight glass’s size, this takes 30 minutes. If the factory needs two employees to perform this task, and if so, at what salary? The cost of performing this procedure is roughly $75/hr. This translates to about $450/year for one sight glass inspection.

Maintenance

Over five years, sight glass maintenance has been the most fixed-cost contributor, routine inspection, cleaning, and repair/replacement. These are the three vital elements of a maintenance plan.

Cleaning

Every person who has ever used or seen a sight glass in action is aware that with time, the glass gets dusty and hazy, making it impossible to read the level. Yet, most plants have regular cleaning schedules. Some end users choose to wait until the liquid level is no longer visible before doing a cleaning. At the same time, it takes so long to clear sight glass. For this illustration, let’s assume that sight glass requires cleaning every two years.

What do bubbles in a refrigerant sight glass mean?

Some refrigeration systems are starting up, and the system has a heavy load. Then, the sight glass downstream of the receiver may bubble and flash. A pressure drop at the receiver’s outlet tube’s entry is what’s causing the bubbling. Additionally, when loads increase, bubbling could happen.

Otherwise, A low flow rate sight glass and a bubbling sight glass are very different—a pressure decrease results in liquid flashing. Also, an undercharge of refrigerant causes vapor. Yet liquid exit receiver due to deficient sub cooling shown by entrained bubbles in the liquid.

What are the colors of refrigerant sight glass?

Most glasses feature indicators for moisture. The indicators change color. Whereas depending on how much moisture is present in the refrigerant. With the removal of moisture, some turn from yellow to green. Some people switch from pink to purple.

How do you charge refrigerant with sight glass?

To reach equilibrium, allow the system to run at this high heat loading for a while. Charge refrigerant vapor into the system’s low side if the sight glass is bubbling. And keep doing so until it stops.

What does a clear sight glass mean?

An operating system’s clear sight glass often indicates a full line of liquid (or flat, but you would know that already if you have gauges attached). Reading sub-cooling only establishes that the system has a full line of liquid, essentially what a sight glass accomplishes.

Selecting the Right Sight Glass for a Refrigeration System

Diverse mechanical and hardware systems necessitate the right sight glass.

- System Capacity: Larger systems might prefer larger sight glasses for more precise observations.

- Location: Ideally, it should be in a spot easily accessible for consistent monitoring.

- Sensitivity to Moisture: Opt for a moisture-indicating sight glass if the system is moisture-sensitive.

Conclusion

The Refrigerant Sight Glass, though seemingly modest in stature, plays a pivotal role in the Safety and efficiency of refrigeration systems. Its presence ensures optimal performance, signaling technicians about the system’s health and potential issues, thereby preventing costly damages and inefficiencies.