An Introduction and Operational Overview

Check valves, sometimes called one-way or non-return valves, are a unique type of valve that allows fluid (liquid or gas) to flow through it in only one direction. These valves are used in various applications to prevent backflow, which could harm the system or its components.

Understanding Check Valves

Check valves are quite straightforward in design but play a critical role in ensuring system integrity. They are typically automatic, meaning they work without external input. Instead, they rely on the pressure differential in the fluid to open or close.

Components of Check Valves:

- Body: The main structure that houses the internal components.

- Opening Mechanism (disc or flap): This is what allows or prevents the flow of fluid. The design and orientation of this mechanism determine the valve’s operation.

- Seat: A crucial part of the valve where the opening mechanism rests. The tightness of the fit between the seat and the opening mechanism ensures that there is no backflow.

How Check Valves Work

The operation of a check valve is all about fluid dynamics:

- Forward Flow: When fluid flows in the intended direction, the pressure differential pushes the opening mechanism off its seat, allowing it to pass through. The valve remains open as long as the fluid keeps moving.

- Reverse Flow: If the fluid tries to flow in the opposite direction, the pressure differential pushes the opening mechanism against the seat, creating a seal. This action prevents any backflow.

Different types of check valves use various mechanisms to achieve this:

- Swing Check Valves: Utilize a flap or door that swings on a hinge or trunnion. The flap swings off its seat in one direction to allow forward flow and swings back onto the seat to block reverse flow.

- Lift Check Valves: Have a disc or piston that lifts off its seat with forward pressure. The disc or piston returns to its seat when the pressure drops or reverses.

- Ball Check Valves: Use a free ball to move within the valve chamber. The ball rests against the seat with no flow and is pushed away during forward flow. Reverse flow pushes the ball back against the seat, stopping any backflow.

- Diaphragm Check Valves: Use a flexible rubber diaphragm that opens during forward flow and seals against a contoured seat during backflow.

Check valves are silent guardians in many fluid systems, preventing damage and ensuring that operations proceed without hindrance. Their simplicity in design is offset by their critical role in safeguarding systems from potential damage due to backflow. When selecting a check valve, it’s essential to consider the fluid type, flow rates, pressure differentials, and the application’s specific requirements. This ensures that the chosen valve provides optimal performance and longevity.

Standard Raw Materials

There are common materials used to manufacture check valves

- Stainless Steel: This material is often chosen for its corrosion resistance, strength, and capability to withstand high temperatures and pressures. Stainless steel check valves are ideal for more industrial applications.

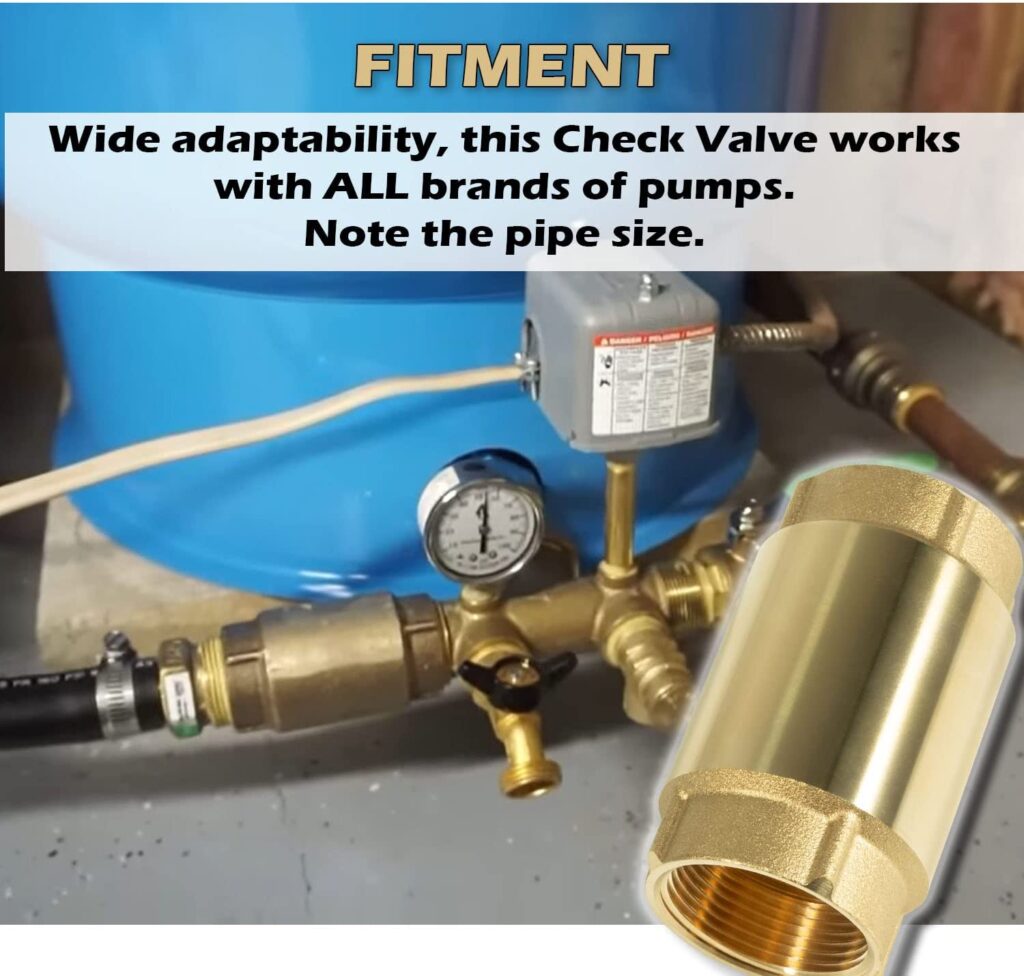

- Brass: A popular choice for its corrosion resistance and good thermal conductivity, brass check valves are commonly employed in plumbing and heating systems. More than 70% of house building, construction, and water fluid control are choosing this brass raw materials.

- Bronze: Mainly composed of copper, bronze offers a good level of corrosion resistance, especially from water, making it well-suited for marine applications.

- PVC (Polyvinyl Chloride): Particularly useful for low-pressure systems and corrosive environments, PVC check valves are commonly found in wastewater and chemical processing operations.

- Ductile Iron (Cast iron): Recognized for its robustness and resilience, ductile iron is frequently used in high-pressure industrial and gas pipeline settings. Because it can make more thickness with full port and keep it solid, and the cost is cheaper, it’s a good selection also.

Standard Sizes of Check Valves Manufacturing

- Standard Sizes: Ranging manufacturing from 1/2 inch to 4 inches in diameter of the thread connection, these are the sizes most commonly encountered in residential and commercial applications.

- Custom Sizes: Custom-sized that from 6″-24″ check valves can be manufactured for unique needs and specific industrial applications.

The selection of raw materials for a check valve largely hinges on the specific application for which it is intended. Factors like the nature of the fluid, temperature range, pressure levels, and the possibility of exposure to corrosive elements will influence the choice of material. Similarly, the valve size must align with the system’s flow rates and pipe sizes for optimal efficiency.

Popular Types Check Valves

This valve comes in a variety of types. Each one is suitable for different applications and purposes. Read on to choose the best suit for your needs.

Swing Check Valve

This variant is probably the most widely used of all other check valves. It works on a simple principle like opening and closing a door. There is a disc with a hinge that is installed inside the valve. The disc swings up and down with the help of the hinge to control the media flow.

The flow power pushes the disc up when the fluid enters the valve through the inlet. Therefore, it makes the path flow. The disc does not come down until the pressure becomes low. After that, when the flow stops, the weight of the disc forces the hinge to go down. As a result, it seals the path, and no backflow occurs.

Spring Check Valve

The spring check valve is yet another popular one. This valve has a spring attached to an obstructive element. Although the spring is pretty weak, it can hold the element with the valve seat.

For the flowing force, the obstructive element goes against the spring and presses it to go backward. Thus, the valve seats open and allow it to flow. After the force stops, the spring repeatedly kicks the element to seal the seats. Therefore, it prevents everything that tries to come back.

Ball Check Valve

The mechanism of the ball check valve comes in two variants. One is the spring-load ball, and the other is the free-flow ball. The working procedure of the spring-load one is similar to the spring check valve. Everything is the same, and just the ball replaces the obstructive element.

In the free-flow ball variant, the ball can move anywhere inside the valve without any interruption. The seat of this valve is machined perfectly to fit the ball. In addition, the chamber has a spherical design for leading the ball into the seat and sealing it.

Diaphragm Check Valve

The diaphragm check valve consists of the inlet port, the outlet port, and a flexible rubber diaphragm. The diaphragm is placed inside, and pressure is applied back from the outlet port for sealing. To open this valve, the flow pressure from the inlet side must be greater than the pressure from the outlet side. However, this valve always acts like a normally closed valve.

Tilting Disc Check Valve

Last, the tilting disc check valve is similar to the swing one. It also works with a disc that tilts like a flipping coin but halfway. The disc hangs with a handle and covers the seat. It can tilt up to 180 degrees because other mechanism does not allow it to tilt completely.

Once the media flow starts, it hits the disc at the bottom and forces it to go horizontal. Therefore, media can flow efficiently without any interruption. Finally, after the flow stops, the disk becomes vertical again to prevent backflow.

SIERRA Engineering & Manufacturing

Applications Check Valves

As you already know, check valves to prevent media backflows. This is their innate purpose. However, check valves are primarily used in pipelines. And without it, there is a big chance of water hammering in the pipes. A water hammer will easily damage your pipes badly. Also, it saves the original media from mixing with other things from the outside. So, using a check valve to stay safe from these problems would be best.

Because of their variety and unique functions, you will see them in almost every industry. Firstly, your domestic applications, such as washing machines, wastewater lines, lawn sprinklers, dishwashers, and check valves, do a great job. This keeps contaminated water away from the main water supply to ensure the water stays fresh.

Check valves are also used in many industrial applications that you cannot finish counting. For Example, pump or lifting systems, water circulation lines, processes, gas mixing systems, air compressors, HVAC, and boilers. All of these applications require a barrier in the backflow. That is why check valves are so popular there.

Above all, you can now assume that you can use check valves… and which type would best suit that application.

Check the Valve Buying Guide

You are now just one step behind from using check valves that is buying them. Follow these selection criteria when purchasing:

· Think about whether the valve construction material is compatible with your application. Not all the material suits all types of media. To get a durable and efficient service, you should choose brass valves. Most importantly, brass is suitable for almost all types of media.

· Properly check the valve’s max pressure, cracking pressure… and temperature tolerance capabilities.

Pick the decent type and right size to match your application perfectly.

Consider the direction of your preferred installation, horizontal or vertical.

Do not forget the other requirements such as flow direction, response time, normally open or closed, and access for maintenance.

However, sometimes it isn’t easy to choose the right one and buy a quality valve. But nothing to worry about until Plumberstar is here. From the Plumberstar factory, you can take expert advice on selecting a valve. Also, all kinds of premium-quality check valves… and other valves are available at affordable prices at the Plumberstar factory.

Hopefully, you got enough knowledge from this post to use the check valves. So, you can start using them now. And for more plumbing help, do not miss our regular blog.