Benefits

The manifold gauge is the chamber device applied to measure the flow of gases or pressure. The manifold sets and reads the pressure of the different air condition systems as they operate.

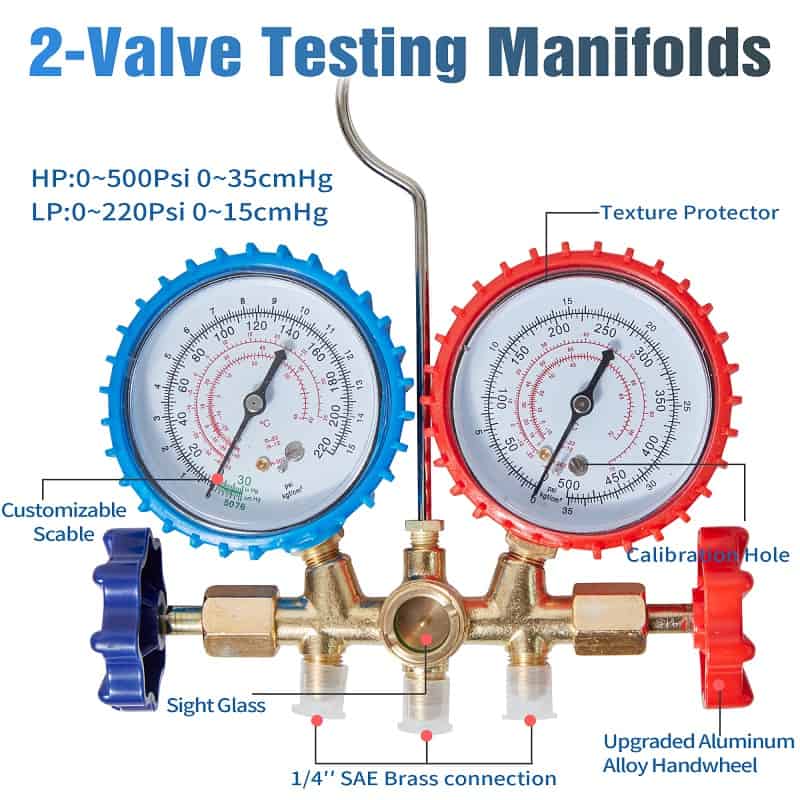

Parts of Manifold Gauge

The manifold gauges will differ between the producers. Yet, most manifold gauges have similar components. It consists of low-pressure and high-pressure valves. Yet, the three hoses are attached to this valve. Yet the red hose connects to the high-pressure valve. On the other side, blue hoses link with the low-pressure valve. The third hose, which is yellow, exists in the center. This yellow hose is directed to either the valve.

The manifold is where all these valves and hoses are attached. That’s why this tool is known as the manifold gauge. Some parts of the standard manifold gauge

· High-pressure valve

· Low-pressure valve

· Low-pressure gauge (blue)

· High-pressure gauge (red)

· High-pressure hose (red)

· Low-pressure hose (blue)

· Middle hose (yellow)

The manifold gauge set is either digital or analog. Some gauge has extra functions or valves and relies on the following:

· inclusions

· brand

· and other considerations.

Design of Refrigeration Manifold Gauge

Manifold gauges have low and high-pressure gauges. Yet, some older manifold gauges come with a design of three meters. One is applying for measuring compressor output. A downside calibrates from 0 to 100-250 psi. Yet, the older high-side manifold gauge calibrates from 0 to 500 psi. On the other hand, the new various gauge designs can be calibrated from 0 to 250 psi. Besides the pressure scale, the latter also has a provision for calculating 0 to 29.9″ of vacuum, which is approx. 50 microns.

How Does a Refrigerant Manifold Gauge Work?

A manifold gauge works by sending a stream of gas through the set. Yet the yellow hose links with an outside source. For example, a vacuum siphon or refrigerant bottle. Relying on the condition, the low-pressure blue and high-pressure red valves link.

The following are a couple of instances of how manifold gauges work:

- Pressure Readings:

While taking pressure readings, the red hose will link with a high-pressure air conditioning line. Yet, the blue hose would be related to a central air low-pressure line. Then, the primary air specialist would look at the gauges and record the reading.

- Vacuuming:

In the case of vacuuming, the yellow hose links to a vacuum siphon, and the blue hose goes to the unit. The blue valve would be left open so the siphon could work.

- Adding Refrigerant:

The yellow hose will link with the outside source if the refrigerant is added to an air conditioner unit. Yet, the unit will be associated with the refrigerant bottle and the red hose. The central air expert would check how much refrigerant is added to the framework. It turns it off when it comes to the right amount.3

How to Pick the Refrigeration Manifold Gauge Set?

A simple air conditioning manifold gauge is fine for regular cooling framework upkeep. Yet, this is beyond what we can deal with without spending more on a digital gauge.

1. Durability

The upkeep of your cooling framework is not a one-time thing. You want to keep it every once in a while. So, while purchasing an analog gauge set, you want to consider the materials utilized. Yet, it’s vital to know about the precision of the kit.

2. Normalized color coding

You want to pick a gauge set with normalized colors of blue and red for analog gauges. To assist you with distinguishing the low and high-pressure sides and ensure appropriate use.

3. Number of ports

Regularly, a three-port manifold is enough for general tasks. Four ports might be vital for vacuum pull applications and large air frameworks.

4. Refrigerant Similarity

Modern air conditioning frameworks utilize different refrigerants. It is R134A, R12, R22, and R502 refrigerants. So, you must ensure that your autos’ air conditioning manifold strain gauge set is viable. Yet, make sure to clean the hoses and manifolds after each use.

5. Cost

Your budget plan is attached to the sort and quality of air conditioning manifold set you can manage. While it might appear enticing for a unit to have each element, costly units can separate without cautious support. Buying a HAVC measure that will meet your maintenance needs is essential.

Important Features to Consider

The ideal manifold gauge set should be reliable and suitable for your auto. Yet, it was built by a recognized firm. Additionally, it must fit your choices and perfect your kind of refrigerant. Here are some features of a refrigerant manifold gauge set.

Compatibility of Refrigerants

Refrigerant compatibility factors must be considered when buying a manifold gauge set. A gauge set for R-12 is created to work with the Freon 12 refrigerant used in autos built before 1993. Yet, meters for 143a are compatible with more recent cars. Yet, most manifold gauges are made to work with various refrigerants. Yet, it’s vital to check everything first.

Scale Size:

Large gauges will be easier to read than smaller gauges. The diameter is; Size2 ½ inches4 inches3 1/3 inches. You will need a good size for manifold gauges. Yet, it is built to read pressure values for different refrigerants. Otherwise, your readings might not be reliable.

Other Elements

Hose material and length are other factors to consider. Choose high-quality materials that won’t rust or break. Yet, it must be flexible hoses that are suitable for your application. Additionally, you may need to choose between analog and digital gauges. The analog AC gauges are less expensive. Yet, they must make more effort to read. Digital versions cost more but are easy to understand. Make wise choices based on the benefits you stand to get.

A refrigeration manifold gauge set depends on many factors. This covers only the gauges, AC hoses, and manifold blocks. A more stylish model gives extra accessories and digital readouts. This elegant model offers accurate pressure gauge interpretations. Understanding features and working is vital when choosing between the analog and digital manifold gauge set. For instance, the best digital mangolds gauge set offers extra functions to offer more data about the condition of the AC system. Uses of Refrigeration Manifold Gauge SetThe manifold gauge was applied to observe the cooling and heating system. Yet, it monitors the pressure of the refrigerant. Here are some critical applications of manifold gauge: It measures the pressure in AC lines, checks the leakage if it occurs, Adds a small number of refrigerants, RechargingTroubleshootingRefrigerants evaluation, and repairs the HVAC and AC system.

Most gauges can be used to check any refrigerant pressure. Yet, each may have a different purpose and set of features. The refrigerant used by the HVAC system and the manifold gauge are compatible. A label identifying the refrigerant will be present in the heating and cooling system. Some gauge sets can read several refrigerants. To get the correct refrigerant reading, you must use the appropriate gauge.

How to Read Refrigeration Manifold Gauge Sets?

You must understand what each reading implies when using AC manifold gauge set readings to assess the condition of the AC system. The tool won’t assist you in fixing the system. It also determines when to add or expel refrigerant.

It’s vital to note that the blue low-pressure gauge calibrates to check both;

· System pressure (psi)

· And system vacuum before continuing.

- Manifold Gauge Reading: High-pressure side

You may face one of these issues if the reading on the high-pressure side (red gauge) is higher than stated in the automobile manual.

· air conditioner

· the air in the system,

· or insufficient airflow through the evaporator

The refrigerant level or quantity is low if the pressure is below the ideal range. Ultimately, the compressor is defective.

- Low-Pressure Side Reading on the Manifold Gauge

This reading is from the AC gauges on the low-pressure side (blue). A higher value over the amount recommended by the producers indicates that the compressor is broken. Yet, there is too much refrigerant in the system. The airflow across the condenser is insufficient if the pressure is too low.

Reading the manual with most manifold gauge sets is vital before using them. It is because it provides guidelines on how to use them for particular car makes and models.

Additionally, the manufacturer will have a site where you may understand more about their services and problems.

Types of Refrigeration Manifold Gauge

- Analog Gauge

These are the most utilized gauges. Yet, they are not difficult to handle and read. In the analog gauge, the needle position shows the strain. There are generally various color regions on the substance of the dial.

Yet, these let you know the refrigerant’s temperature at that pressure. This makes it simpler than taking out a P/T graph and finding it each time the needle moves. These gauge manifolds use Bourdon tubes, changing pressure into mechanical energy.

Users of analog gauges will sometimes dismantle the check to perform changes by correcting the false readings. This needs the client’s ability or chance of human mistake in changing the assignments or harming the manifold gauge.

- Digital Manifold Gauge

Compared with analog gauges, digital manifolds are more proficient. They give the pressure readings in numbers down to 1/10 of a PSI. You don’t have to change the readings, decreasing the possibility of making mistakes.

Features:

Maximum Pressure: The digital manifold gauge can check the pressure of a given coolant gas. So, it should have the option to look at high pressures for a rational check. So, they offer the most significant strain changes, like up to 50 or 60 bar, where a higher rating is better.

Warranty: Regardless of whether you purchase a solid digital manifold gauge, you expect that yours should be kept for a long time without any issues. Because of this, checking the warranty given by your manifold gauge is very significant. Most of the regular warranty time frames incorporate a one-year or 2-year warranty. But with a couple of models offering a 3-year warranty for a high life span.

Calibration: A calibrated digital pressure gauge remains calibrated more than a pressure measurement with simple output. The software does a Digital calibration gauge, so it’s substantially more precise.

Number of Refrigerants: Aside from having the option to check high pressure, your digital manifold gauge is also viable with the refrigerant or coolant gas you are topping off. Fortunately, specific models could uphold up to 80 refrigerants. The different models support up to 140 refrigerants.

Choose a Brass or Aluminum Manifold Gauge Set

The material from which the set is made does not affect the nature of the gauge. Yet, it is only a question of individual choice. The quality of a gauge set is assessed by how well it gets through corrosion and high tension from the refrigerant. Another quality indicator is the accuracy with which the parts were made. This decides the probability of spillage.

Although metal aluminum is more affordable than brass, aluminum manifold sets might be costlier. For instance, it has a sight glass to note the flow of refrigerant, a feature many specialists want.

It is more significant than the material they produced. Buyers worry about the quality of the set and the presence of required features. The most considerable contemplations are:

- Value

- Gauge protectors

- Needed adaptors

- Sight glass

- Significant, easy-to-read color changes

- User friendly

- Refrigerants compatibility

- Accuracy