Description

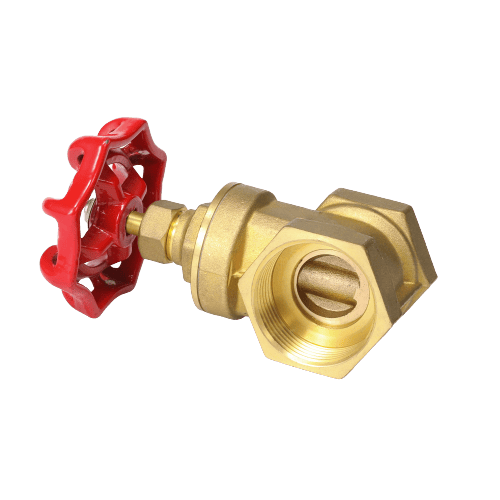

Brass Gate Valve

JX-0751

Brass Gate Valve

Applicable Media: steam, water, oil, and gas; Working Temp: 0 to 300 Degrees F

Brass Forged Body

Female x Female NPT, IPS

Pressure rated: 200WOG & 125WSP

Non-rising stem

Cast Iron Handle

Suitable for a full range of liquids and gas

Flow can go in both directions

Each valve is individually tested

Threaded ends to ANSI

200 WOG,1/2 inch Brass Gate Valve

Dimensions: through 1/2 to 1 inch

What Is a Gate Valve?

A gate valve is named after the internal mechanism that enables water flow. This mechanism looks like a bit of gate that moves up and down on a stem connected to the handle. The handle is a screw handle that moves the gate up and down, opening and closing the valve as needed. They are best used in on/off applications where the valve is used infrequently. They are sometimes found in home plumbing systems, though ball valves are becoming more popular in this area. They are also commonly found in the oil and gas industry, pharmaceuticals, manufacturing, automotive, and marine applications. They can be used in high-pressure and high-temperature environments often found in manufacturing.

A brass valve is a type of valve that regulates fluid flow through pipes. This type of valve typically has a stem and screw mechanism that can be rotated to stop or start the flow in one direction. Gate valves usually have an opening gate, which allows for quick closing when maintenance (or emergency) work is required on the system. Water systems often use brick gate valves to withstand high pressure and temperature fluctuations. However, brass is also relatively expensive, so it’s not commonly used for other fluid systems.

It is usually used in water systems to regulate fluid flow through pipes.

A brass gate valve can also be used in other fluid systems; however, it’s not commonly used for this purpose because brass is expensive.

Its opening gate allows for quick closing when maintenance (or emergency) work is required on the system.

A brass gate valve’s screw mechanism and stem can be rotated to stop or start the flow in one direction.

This type of valve typically has a stem and screw mechanism that can be rotated to stop or start the flow in one direction.

Gate valves usually have an opening gate, which allows for quick closing when maintenance (or emergency) work is required on the system.

When closed, the valve forms a watertight seal, which prevents fluid from flowing through it.

There are a total of four sizes of brass gate valves which are:

-The size being 1/2″,3/4,1″,11/4″,11/2″,2″,21/2″,3″ and 4″

Gate valves have an opening gate, which allows for quick closing when maintenance (or emergency) work is required on the system. A Brass Gate Valve can also be used in other types of fluid systems;

A gate valve, sometimes called a sluice valve, is a type of valve that uses a gate or wedge to regulate or stop the flow of a fluid. It is one of the oldest and most common types of valves. The gate or wedge moves linearly, perpendicular to the direction of flow. When the valve is fully open, it offers minimal obstruction to flow, making it suitable for applications that require minimal flow resistance.

Key Characteristics of Gate Valves:

- Operation: Unlike most valves, gate valves are either fully open or fully closed. They are not ideal for throttling purposes, as partially opening the valve can cause vibration, accelerated wear, and damage to the valve.

- Flow Path: When open, gate valves provide a straight-through, unobstructed path for fluid flow. This results in very low flow resistance and minimal pressure drop.

- Seating: Gate valves can be either metal-seated or soft-seated. Metal-seated valves are more durable and can withstand higher temperatures, while soft-seated valves offer a tighter seal.

- Visual Indication: One disadvantage of gate valves is that they don’t provide a quick visual indication of their open or closed status, unlike ball or butterfly valves.

- Material: Made primarily of brass, these valves are resistant to corrosion, especially when compared to iron or steel valves. This makes them ideal for applications involving water.

- Full Bore Design: This ensures minimal pressure drop when the valve is fully open.

- Durability: Brass gate valves are known for longevity, especially when used in applications best suited for them.

Types of Gate Valves:

- Rising Stem: This is the traditional design where the stem rises along with the gate as the valve is opened. It allows visual confirmation of the valve’s status but requires more vertical space.

- Non-Rising Stem: In this design, the stem remains stationary while the gate moves. It’s beneficial for spaces with height restrictions.

- Wedge-Shaped Gate: Features a solid wedge gate commonly used in various applications.

- Parallel Slide Gate: Uses two parallel discs and a spring mechanism to keep them pressed against the valve body.

Applications of Brass Gate Valve

Gate valves are typically used in applications where the flow must be stopped entirely or fully allowed. They are often found in:

- Water and wastewater treatment plants for isolating sections of the pipeline.

- Oil and gas industry for isolation purposes.

- Industrial plants where on/off control is required without throttling.

- Building services for hot and cold water distribution.

Gate valves are essential components in many piping systems. Their primary function is isolation, and they excel in applications where minimal flow obstruction is a priority. However, they are not suitable for throttling. When selecting a gate valve, considerations regarding size, material, type, and application requirements are crucial for optimal performance.

Brass gate valves are utilized in various sectors, including:

- Residential Plumbing: For controlling the flow of water in household pipelines.

- Industrial Settings: On/off control of liquids and gases is essential in factories and manufacturing units.

- Agriculture: In irrigation systems to control water flow to fields.

- Commercial Buildings: For controlling water supply in large complexes.

Types of Brass Gate Valves:

- Standard Brass Gate Valve: This is the most common type, featuring a simple design with a rising stem and a wedge gate. It’s suitable for various general purposes and is often found in residential plumbing systems.

- Non-Rising Stem Brass Gate Valve: The stem remains stationary when the valve is opened or closed. This design is typically used in spaces with limited height availability.

- Solid Wedge Gate Valve: A solid wedge gate is a single-piece, rigid design that offers strength and durability. This is the most widely used design for brass gate valves.

- Split Wedge or Parallel Disc Gate Valve: This design employs two separate discs that move together. It can automatically adjust and align to seating surfaces, reducing wear and ensuring a tighter seal.

Key Features of Brass Gate Valves:

- Corrosion Resistance: Brass inherently resists corrosion, especially against water. This makes brass gate valves ideal for water supply lines and related applications.

- Durability: Brass gate valves have a long lifespan and can withstand various environmental conditions, including fluctuating temperatures and pressures.

- Cost-Effective: Although brass is slightly more expensive than other materials, its durability and longevity make it a cost-effective choice in the long run.

- Compatibility: Brass is non-sparking and is compatible with a wide range of substances, from water to gas to certain chemicals, making brass gate valves versatile for various applications.

Advantages:

- Low-Pressure Drop: When fully opened, the gate valve design allows for a straight-through flow and, thus, minimal pressure drop.

- Tight Seal: When closed, the gate valve offers a very tight seal, making it suitable for applications requiring complete shutoff.

- Durability: Brass construction offers enhanced corrosion resistance and longevity.

However, it’s essential to note that gate valves should not be used for throttling, as they are designed primarily for on/off service. Using them for throttling can wear out the valve prematurely.

Conclusion:

Brass gate valves offer a combination of durability, versatility, and functionality. Their inherent corrosion resistance, suitability for various applications, and longevity make them an ideal choice for many sectors. When selecting a brass gate valve, it’s crucial to consider its type, the specific requirements of the application, and the conditions it will be exposed to.

How do you choose a gate valve supplier?

1. Determine Your Requirements:

- Application: Understand the application where the valve will be used. This includes the type of fluid, operating temperature, and pressure.

- Specifications: List the technical specifications like size, type (OS&Y, NRS), material (brass, stainless steel, etc.), and any special requirements.

2. Research and List Potential Suppliers:

- Referrals: Check with industry peers, associations, or forums for recommended suppliers.

- Online Directories: Platforms like Alibaba, ThomasNet, or Google can help identify potential suppliers.

3. Evaluate Suppliers Based on Critical Factors:

- Experience & Reputation: Check how long the supplier has been in the market. Look for customer reviews or testimonials.

- Quality Assurance: Ensure the supplier adheres to international standards like ISO. Ask for certifications.

- Product Range: A supplier with a diverse product range can cater to varying requirements.

- Technical Support: A good supplier offers technical support for product selection, installation, and maintenance.

- After-Sales Service: This includes warranty, return policies, and promptness in resolving any issues.

4. Request and Review Quotations:

- Seek detailed quotes from shortlisted suppliers. This should include product specifications, pricing, delivery timelines, payment terms, and other essential details.

5. Visit the Supplier (if feasible):

- Personal visits can provide insights into the supplier’s manufacturing capabilities, quality control processes, and organizational culture.

6. Evaluate Price vs. Value:

- Don’t choose solely based on price. Consider the overall value, including quality, durability, after-sales service, and other benefits.

7. Check References:

- Before finalizing, contact some of the supplier’s past or current customers. They can provide firsthand feedback about their experiences.

8. Start with a Trial Order:

- Before placing a large order, start with a smaller quantity to assess product quality and service reliability.

9. Negotiate Terms:

- Discuss payment terms, delivery timelines, warranty, and other pertinent details. Make sure to get everything in writing.

10. Build a Relationship:

- Building a long-term relationship with a supplier can lead to better prices, priority service, and a mutual understanding of expectations.

The right supplier is not always the one with the lowest price but provides the best value for your investment. The effort spent selecting the right gate valve supplier can lead to long-term benefits and fewer headaches.