Valves are essential components in the industrial field, primarily used to control the flow of liquids or gases. The valve industry has a huge market size due to its critical role in various important sectors such as petroleum, natural gas, food processing, pharmaceuticals, water treatment, etc. As the global industry continues to develop, the demand for valves will grow.

Valves have become an indispensable part of our lives, effortlessly controlling the flow of fluids and gases we rely on daily. The valve spectrum spans two vast domains – the household and the industrial. While their core functionality remains analogous, the design, application, and requirements vary considerably. This article provides a deep dive into household and industrial valves, elucidating their key differences and why they matter.

Introduction: The Vital Role of Valves

Valves play a pivotal role in our homes and colossal industrial complexes. From the faucet you open for a morning splash to the intricate pipelines of a petrochemical plant, valves ensure precise control and safety. But what exactly distinguishes a household valve from its industrial counterpart?

Core Functions: The Basics

Household Valves:

- Primarily cater to domestic needs, including controlling water flow in showers, faucets, and appliances.

- It may regulate gas, especially in household appliances like heaters or stoves.

Industrial Valves:

- Designed for a plethora of applications, be it oil refineries, wastewater treatments, or power plants.

- They deal with a diverse range of substances, including aggressive chemicals, steam, or combustible gases.

Dimensions and Design Specifications

Household Valves:

- Compact, tailored to standard domestic plumbing lines.

- They can operate at relatively low pressures and are often manually operated.

Industrial Valves:

- Range from medium-sized to enormous valves for large pipelines or tanks.

- Built for high pressures and flow rates. Automation is common, using actuators or computerized controls.

Materials and Resilience

Household Valves:

- Predominantly composed of brass, plastic, bronze, or stainless steel.

- These valves are designed to be rust-resistant, catering to domestic water and gas supply needs.

Industrial Valves:

- Depending on their application, it is fabricated from specialized materials, from durable plastics to exotic alloys.

- It must often withstand extreme conditions, whether high temperatures, aggressive chemicals, or abrasive materials.

Complexity and Design Variants

Household Valves:

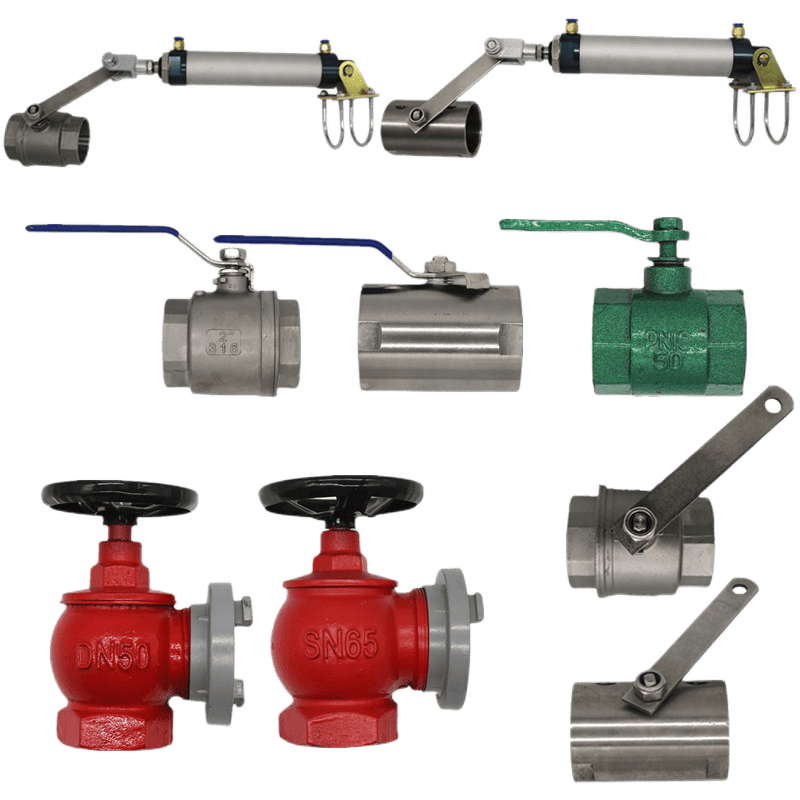

- Designs are relatively simple, ranging from ball valves and gate valves to mixer taps.

Industrial Valves:

- Complex designs tailored to specific industry needs. Variants include pressure relief, butterfly, diaphragm valves, and many more.

- Often incorporate advanced features like pressure sensors, flow rate monitors, or automated control systems.

Market Size

The global valve market size is approximately USD 50 billion and is expected to reach USD 60 billion by 2025. The Asia-Pacific region has the highest consumption of valves, accounting for 33% of the global market. This increased demand is mainly driven by the significant need for valves in the sectors propelling economic growth in Asia.

Industry Competitive Landscape

Competition in the valve industry is fierce, with continuous research and innovation being the primary way to improve product quality and performance. Large valve manufacturers and international brands occupy a relatively large market share, with companies like Honeywell, Emerson, and Tyco being the top “giants” in the market.

Future Development Trends

(1) Correlation with Industry 4.0 – People are hoping to use new technologies such as real-time monitoring and data analysis to improve production efficiency and reduce costs. Therefore, the valve industry will shift towards digitization, providing more comprehensive data collection and monitoring solutions.

(2) Energy conservation and environmental protection are the main themes. With increasing global attention on energy conservation and environmental protection issues, the valve industry will focus more on energy conservation and environmental protection. The design of the new generation of valves will be more innovative to achieve higher efficiency and reduce environmental damage.

(3) Product diversification – The emergence of various valve types, such as hydraulic, electric, pneumatic, and manual valves, will cater to different application needs, such as pressure relief, isolation, gate, and control valves. This will increase market segmentation and competition in the industry.

As the global industry develops, the valve industry market will expand further. However, with increasing competition, companies will need to continue to improve their product quality and performance to gain a larger market share in the fiercely competitive market.

Difference between industrial valves and household valves?

There are significant differences between industrial valves and household valves. Industrial valves are mainly used in various industrial sectors such as petrochemicals, water treatment, electricity, and mining. On the other hand, household valves are used in the pipeline systems of homes or commercial buildings, such as bathrooms, kitchens, and public restrooms.

Industrial valves are typically made from cast iron, steel, and stainless steel and have intense heat and corrosion resistance. In contrast, household valves are usually made from copper and brass alloys such as cast copper and forged copper and are generally smaller in size and less complex in design.

Industrial valves must meet performance and specification requirements to withstand harsh usage environments and meet relevant standards and regulations. In contrast, household valves must be stable and safe to use, operate easily, and meet national standards and regulations.

Standard household valves include globe, ball, axial flow control, and cast iron gate valves. The specifications, pressure, temperature, and other characteristics of household valves vary depending on the type and application. For example, globe and axial flow control valves are mainly used in hot and cold water systems, while ball valves are commonly used in gas or liquid pipelines.

Analyze the characteristics of standard household valves, such as styles, materials, specifications, pressure, and temperature.

Standard household valves are plug, ball, axial flow control, and cast iron gate valves. The materials and specifications of these valves can vary widely depending on the type and application. For example, plug valves are typically made from copper or stainless steel, with specifications ranging from 1/4 inch to 4 inches, pressure below 125 PSI (about 8.6 bar), and temperature ranging from -10℃ to 120℃.

Ball valves, which are often used in bathrooms, kitchens, and HVAC systems, have materials ranging from copper to stainless steel, with specifications ranging from 1/4 inch to 2 inches and a pressure range of 100 PSI (about 6.9 bar) or less and temperature going from -20℃ to 200℃.

Plumberstar flow control valves are also often used in showers and water faucets, with materials ranging from copper to stainless steel, specifications of up to 3/4 inch, pressures under 100 PSI, and temperature ranges from -20℃ to 200℃.

Cast iron gate valves are standard and economical, generally used in home water supply pipes. They are made of ductile iron, with specifications ranging from 1/2 inch to 2 inches, pressure below 200 PSI (about 13.8 bar), and temperature ranging from -20℃ to 200℃.

Household valves are smaller, simpler in design, and have lower performance requirements than industrial valves. Therefore, the price of household valves is relatively low. Choosing products from reputable brands and manufacturers with complete certification is recommended when purchasing household valves.

Maintenance, Durability, and Lifespan

Household Valves:

- Moderate lifespan, typically requiring sporadic maintenance.

- Homeowners or local plumbers usually rectify issues.

Industrial Valves:

- They are engineered for longevity and consistent performance.

- Due to the critical nature of many industrial processes, experts rigorously maintain, inspect, and replace these valves.

The Economic Perspective

Household Valves:

- Affordable, considering their scale and application. Readily available at local stores or online platforms.

Industrial Valves:

- Investment-heavy, owing to their specialized design, materials, and features.

- Procurement often involves negotiations, contracts, and relationships with niche manufacturers.

In Conclusion:

The demarcation between household and industrial valves is distinct, with each catering to its specific realm of applications. By understanding these differences, industries and homeowners alike can make informed choices, ensuring optimal performance, safety, and cost-effectiveness. As the world of engineering advances, so will the designs and capabilities of these valves, further refining the boundaries of their applications.