- The majority of floating ball valves cost less than trunnion ball valves. The durability makes trunnion-mounted ball valves a popular choice for heavy-duty uses.

- Floating ball valves help regulate water and work with chemicals.

- A floating ball valve has a ball that floats on a seat. This makes it a lesser probability that it will damage the ball. When you connect a ball to a trunnion, it makes the valve more durable.

What Is Floating Ball Valves?

Floating ball valves contain a ball that floats within the valve’s interior. The handle actuates the stem, which connects to the ball. A lever connects the ball and operates the valve’s opening and closing. Oil and gas, chemical refining, and water treatment are some industries that utilize floating ball valves.

Companies use floating ball valves in applications that require high precision. The ball in a floating ball valve can move freely up and down. It allows it to create a secure seal. It makes floating ball valves suitable for specific applications where minimal leakage is permissible.

How Do Floating Ball Valves Work?

Working mechanism

The stem, or shaft, connects to the top of the ball in the ball valve and turns it 90 degrees. This moves the floating ball valve.

As the ball rotates, the wall of the valve body either covers or uncovers the port. This either passes the media run or stops it. Enough space exists between the stem and the ball so that when it rotates on its axis.

Moreover, the flow pressure pulls it downstream against its seat, making a tight seal. In extremely low-pressure circumstances, moving ball valves might not close well after a certain amount of seat wear. The media does not have enough pressure to push the ball against the seat downstream for a tight seal. Most of the pressure further downstream is enough to keep the seal tight long after the seats wear down.

Floating Ball Valve Applications

-

Applications of a Floating Ball Valve

Floating Ball Valve for water tank

The effectiveness of floating ball valves renders them optimal for the following applications:

Water systems:

Water distribution systems necessitate optimal pressure maintenance to prevent air pockets from impeding and sustaining water flow. Additionally, we must regulate water flow to avoid overflows. A floating ball valve is a water system control device that opens and closes based on pressure.

Emergency shut-off systems:

For emergencies, pipeline systems transporting fuels, water, or gases need a quick shut-off valve. This ball valve works quickly and is suitable for SIL 3 emergency shut-offs because of its unmounted design.

Pipeline pressure relief:

Proper management of pipeline pressure is critical to prevent malfunctions such as bursts. A pipeline uses a floating ball valve as a pressure discharge valve. Unlike a mounted ball valve that can blow out, the floating ball valve can handle the pressure without breaking.

Advantages of Floating Ball Valve

- The mechanism of the floating ball valve is simple, making it easy to understand and use. It works better because of this style.

- The floating ball valve is perfect for pipes and systems circling heavy, thick fluids because it has little flow resistance.

- Their flexibility lets them handle severe pressures. The moving ball valve is flexible enough to handle changes in pressure and temperature. This is because the ball can move inside the valve.

- It seals well, so we don’t see any leaks when the system works. Since leaks are the main reason for losses in a company.

Disadvantages Floating Ball Valve

- The weight of the floating ball tends to settle on the seal ring. It causes it to form irregularly, making it less effective.

- The torque the ball creates depends on friction; if you get the wrong balance, the torque will not work.

- The floating ball inside the valve can’t always handle high pressure, especially if the valve around it is too giant. It leaves too much area for materials to pass through.

What Are Trunnion Ball Valves?

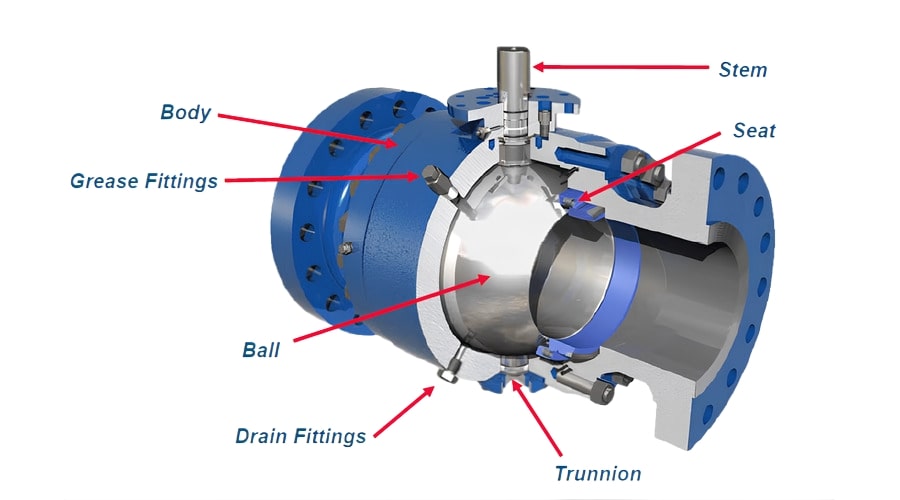

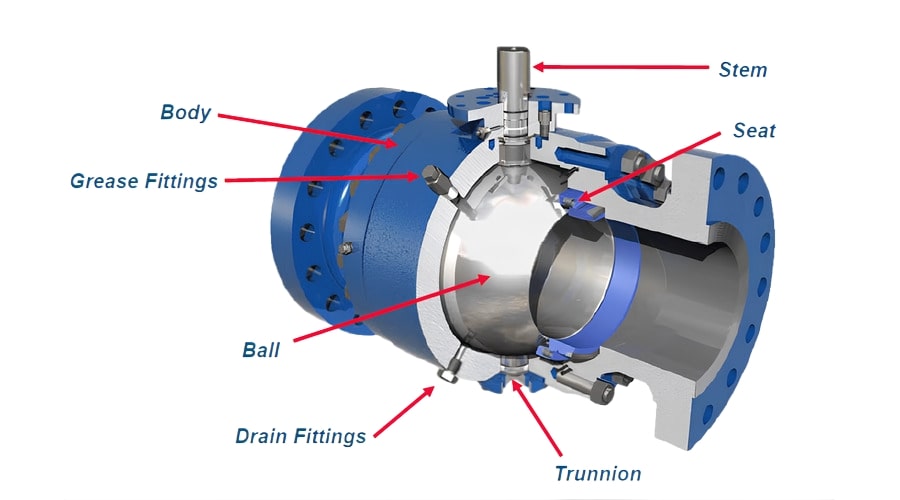

Trunnion ball valves consist of a ball held in position by two trunnions. This design passes the ball rotate, allowing the valve to open or close. This ball valve is a specific valve used in various industries. The purpose of these valves is to provide superior performance in required applications. Trunnion ball valves are available in a range of diameters and pressure ratings to handle the needs of various industries.

How Does a Trunnion Ball Valve Work?

Trunnion ball valves operate by quarter-turn to stop or start the flow of fluid through a pipe. Most ball valves have a “free-floating” design, but the trunnion type differs because it has a fixed structure.

The ball attaches to the stem on one end of a trunnion ball valve, while the other end connects to a trunnion-shaped shaft. This modification to the design holds the ball securely in position. The ball in a floating ball valve attaches only to the stem, so it rates the name floating.

Applications of Trunnion Ball Valve

- Chemical industries

Trunnion ball valves are optimal for various chemical industries because of their superior safety, reliability, and sealing capabilities.

- Oil and gas industries

Trunnion ball valves are suitable for various oil and gas industry applications. Several oil and gas enterprises utilize trunnion-mounted ball valves. It includes gas feed lines, industrial gas processing plants, field gas plants, oil refinery feedstock, and crude oil plants.

- Pipeline industries

Trunnion ball valves are incredibly useful in the pipeline industry. These valves can handle various applications, such as gas, slurry, and fluid transmission.

Advantages of Trunnion Ball Valve

- They feature spring-loaded seats that allow the industrial valve to manage high and low pressures without manual adjustments. These springs help restore equilibrium when pressures drop or abruptly increase without warning.

- You can use it in high-pressure situations because the object is less likely to fail. This ensures the valve maintains a correct closure on both sides without adding torque to the shaft. This gives it the necessary strength to withstand high pressures.

- A trunnion-mounted ball valve is affordable because it can handle excess pressure efficiently. This makes it an excellent option for various operations. This primary mechanism substantially reduces torque, reducing the need to install a large actuator.

Disadvantages of Trunnion Ball Valve

- Due to the fixed nature of the trunnion ball valve, it isn’t very easy to repair or perform maintenance on it. The only option is to shut down the system by manipulating a single valve component. This is a counterproductive action.

- Without appropriate maintenance, the welded sections of the trunnion ball valve begin to operate with increased friction. Moreover, this hurts the valve’s efficiency due to the increased torque and energy consumption.

Trunnion Vs Floating Ball Valve: Design

What are the main differences between a floating ball valve and a trunnion ball valve when comparing? The primary distinction lies in the ball’s design.

The ball in a floating ball valve is unrestricted to float within the valve’s body. This aligns the ball with the mount to create a close seal.

In a trunnion ball valve, the ball attaches to a short, cylindrical portion of metal known as a trunnion. The trunnion serves as a focal point for the projectile. It helps the valve and prevents the ball from cracking under extreme pressure.

Conclusion

There are a few essential aspects to know about floating ball valves vs trunnion ball valves. Because they can handle more pressure, trunnion ball valves work better in high-pressure situations. These valves are better for conditions where leaks are concerned because they are less likely to leak.

The float and trunnion designs are two main types of ball valves. Floating ball valves are the predominant valve variety found in industrial piping systems.

These valves are designed to cause wear on the seats. The engineers intended these valves to wear out the seats. These valves are designed to wear out the seats. The pressure of the media passing through the valve pushes the ball against the downstream seat to create a tight seal.

There are 2 main types of ball valve designs: floating and trunnion. It is most famous for industrial plumbing systems that use floating ball valves. When the seats on these valves start to wear down, the pressure from the fluid moves through the valve. It pushes the ball against the downstream seat to keep the seal tight. This article will explain the floating ball valve vs the trunnion ball valve. Let’s get started.

Floating Ball Valve Vs Trunnion Ball Valve: What Are the Key Differences?

Ball valves include both floating ball valves and trunnion ball valves. Ball valves are valves that utilize a ball to regulate fluid passage. The ball’s central opening enables fluid to pass through when the valve opens. When the valve is fully closed, the ball is rotated to obstruct the opening, preventing fluid from passing through.

- Sealing

Since the ball of a floating ball valve floats, the ball will move against the downstream seat when subjected to the pressure of the medium; therefore, the floating ball valve seal is a single-side seal. In contrast, the ball of the trunnion ball valve is immovable, so both sides must be sealed.

- Appearance

The appearance of the floating ball valve and the trunnion ball valve are readily distinguishable. If the valve body has a fixed axis at the bottom, it is a trunnion ball valve; otherwise, it is a floating ball valve.

- Operation

Both floating ball valves and trunnion-mounted valves have the common characteristic of employing a rotating ball mechanism to regulate the start or stop of fluid flow. The operation of these entities varies, as does their design requirements, which are influenced by factors like pressure, class, bore size, and other relevant variables.

- Risk of leakage

The leakage rate and maintenance requirements of floating ball valves are lower than those of trunnion ball valves. They’re less costly. However, trunnion ball valves can withstand more significant pressures and have better flow characteristics.

- Design

While discussing a floating ball valve vs a trunnion ball valve, what are the key distinctions between a trunnion valve and a floating valve? The primary distinction lies in the ball’s design. The ball in a floating ball valve is unrestricted to float within the valve’s body. This aligns the ball with the mount to create a close seal. However, in a trunnion ball valve, the ball is fixed to a short, cylindrical portion of metal called a trunnion. The trunnion serves as a focal point for the projectile. It helps the valve and prevents the ball from cracking under extreme pressure.

- Pressure

Floating ball valve balls exhibit greater adaptability to variations in pressure due to their ability to move freely in response to changes in valve pressure. In contrast, trunnion ball valves are better suited for situations where pressure remains relatively constant.

Floating Ball Valve Trunnion Ball Valve: Which is Better for Your Application?

When picking between a trunnion ball valve and a floating ball valve, there are many considerations to consider. Both have pros and cons, so the best choice for what you want will depend on many factors. I’ve compiled a quick summary of these two types of floating ball valves vs trunnion ball valves to help you make the best choice.

- The majority of floating ball valves cost less than trunnion ball valves. The durability makes trunnion-mounted ball valves a popular choice for heavy-duty uses.

- Floating ball valves help regulate water and work with chemicals.

- A floating ball valve has a ball that floats on a seat. This makes it a lesser probability that it will damage the ball. When you connect a ball to a trunnion, it makes the valve more durable.

What Is Floating Ball Valves?

Floating ball valves contain a ball that floats within the valve’s interior. The handle actuates the stem, which connects to the ball. A lever connects the ball and operates the valve’s opening and closing. Oil and gas, chemical refining, and water treatment are some industries that utilize floating ball valves.

Companies use floating ball valves in applications that require high precision. The ball in a floating ball valve can move freely up and down. It allows it to create a secure seal. It makes floating ball valves suitable for specific applications where minimal leakage is permissible.

How Do Floating Ball Valves Work?

Working mechanism

The stem, or shaft, connects to the top of the ball in the ball valve and turns it 90 degrees. This moves the floating ball valve.

As the ball rotates, the wall of the valve body either covers or uncovers the port. This either passes the media run or stops it. Enough space exists between the stem and the ball so that when it rotates on its axis.

Moreover, the flow pressure pulls it downstream against its seat, making a tight seal. In extremely low-pressure circumstances, moving ball valves might not close well after a certain amount of seat wear. The media does not have enough pressure to push the ball against the seat downstream for a tight seal. Most of the pressure further downstream is enough to keep the seal tight long after the seats wear down.

Floating Ball Valve Applications

-

Applications of a Floating Ball Valve

Floating Ball Valve for water tank

The effectiveness of floating ball valves renders them optimal for the following applications:

Water systems:

Water distribution systems necessitate optimal pressure maintenance to prevent air pockets from impeding and sustaining water flow. Additionally, we must regulate water flow to avoid overflows. A floating ball valve is a water system control device that opens and closes based on pressure.

Emergency shut-off systems:

For emergencies, pipeline systems transporting fuels, water, or gases need a quick shut-off valve. This ball valve works quickly and is suitable for SIL 3 emergency shut-offs because of its unmounted design.

Pipeline pressure relief:

Proper management of pipeline pressure is critical to prevent malfunctions such as bursts. A pipeline uses a floating ball valve as a pressure discharge valve. Unlike a mounted ball valve that can blow out, the floating ball valve can handle the pressure without breaking.

Advantages of Floating Ball Valve

- The mechanism of the floating ball valve is simple, making it easy to understand and use. It works better because of this style.

- The floating ball valve is perfect for pipes and systems circling heavy, thick fluids because it has little flow resistance.

- Their flexibility lets them handle severe pressures. The moving ball valve is flexible enough to handle changes in pressure and temperature. This is because the ball can move inside the valve.

- It seals well, so we don’t see any leaks when the system works. Since leaks are the main reason for losses in a company.

Disadvantages Floating Ball Valve

- The weight of the floating ball tends to settle on the seal ring. It causes it to form irregularly, making it less effective.

- The torque the ball creates depends on friction; if you get the wrong balance, the torque will not work.

- The floating ball inside the valve can’t always handle high pressure, especially if the valve around it is too giant. It leaves too much area for materials to pass through.

What Are Trunnion Ball Valves?

Trunnion ball valves consist of a ball held in position by two trunnions. This design passes the ball rotate, allowing the valve to open or close. This ball valve is a specific valve used in various industries. The purpose of these valves is to provide superior performance in required applications. Trunnion ball valves are available in a range of diameters and pressure ratings to handle the needs of various industries.

How Does a Trunnion Ball Valve Work?

Trunnion ball valves operate by quarter-turn to stop or start the flow of fluid through a pipe. Most ball valves have a “free-floating” design, but the trunnion type differs because it has a fixed structure.

The ball attaches to the stem on one end of a trunnion ball valve, while the other end connects to a trunnion-shaped shaft. This modification to the design holds the ball securely in position. The ball in a floating ball valve attaches only to the stem, so it rates the name floating.

Applications of Trunnion Ball Valve

- Chemical industries

Trunnion ball valves are optimal for various chemical industries because of their superior safety, reliability, and sealing capabilities.

- Oil and gas industries

Trunnion ball valves are suitable for various oil and gas industry applications. Several oil and gas enterprises utilize trunnion-mounted ball valves. It includes gas feed lines, industrial gas processing plants, field gas plants, oil refinery feedstock, and crude oil plants.

- Pipeline industries

Trunnion ball valves are incredibly useful in the pipeline industry. These valves can handle various applications, such as gas, slurry, and fluid transmission.

Advantages of Trunnion Ball Valve

- They feature spring-loaded seats that allow the industrial valve to manage high and low pressures without manual adjustments. These springs help restore equilibrium when pressures drop or abruptly increase without warning.

- You can use it in high-pressure situations because the object is less likely to fail. This ensures the valve maintains a correct closure on both sides without adding torque to the shaft. This gives it the necessary strength to withstand high pressures.

- A trunnion-mounted ball valve is affordable because it can handle excess pressure efficiently. This makes it an excellent option for various operations. This primary mechanism substantially reduces torque, reducing the need to install a large actuator.

Disadvantages of Trunnion Ball Valve

- Due to the fixed nature of the trunnion ball valve, it isn’t very easy to repair or perform maintenance on it. The only option is to shut down the system by manipulating a single valve component. This is a counterproductive action.

- Without appropriate maintenance, the welded sections of the trunnion ball valve begin to operate with increased friction. Moreover, this hurts the valve’s efficiency due to the increased torque and energy consumption.

Trunnion Vs Floating Ball Valve: Design

What are the main differences between a floating ball valve and a trunnion ball valve when comparing? The primary distinction lies in the ball’s design.

The ball in a floating ball valve is unrestricted to float within the valve’s body. This aligns the ball with the mount to create a close seal.

In a trunnion ball valve, the ball attaches to a short, cylindrical portion of metal known as a trunnion. The trunnion serves as a focal point for the projectile. It helps the valve and prevents the ball from cracking under extreme pressure.

Conclusion

There are a few essential aspects to know about floating ball valves vs trunnion ball valves. Because they can handle more pressure, trunnion ball valves work better in high-pressure situations. These valves are better for conditions where leaks are concerned because they are less likely to leak.