What Are Check Valves

A brass check valve avoids the reverse flow of liquid in a system. This is used in fire protection systems and irrigation. Also, it uses where fluid needs to keep from flowing in the reverse path.

The brass check valve is made from a copper alloy tougher than plastic. Yet, the brass is a blend of zinc and copper. There may be other metals present to increase rust resistance and machinability. Some of these metals are aluminum, lead, and arsenic.

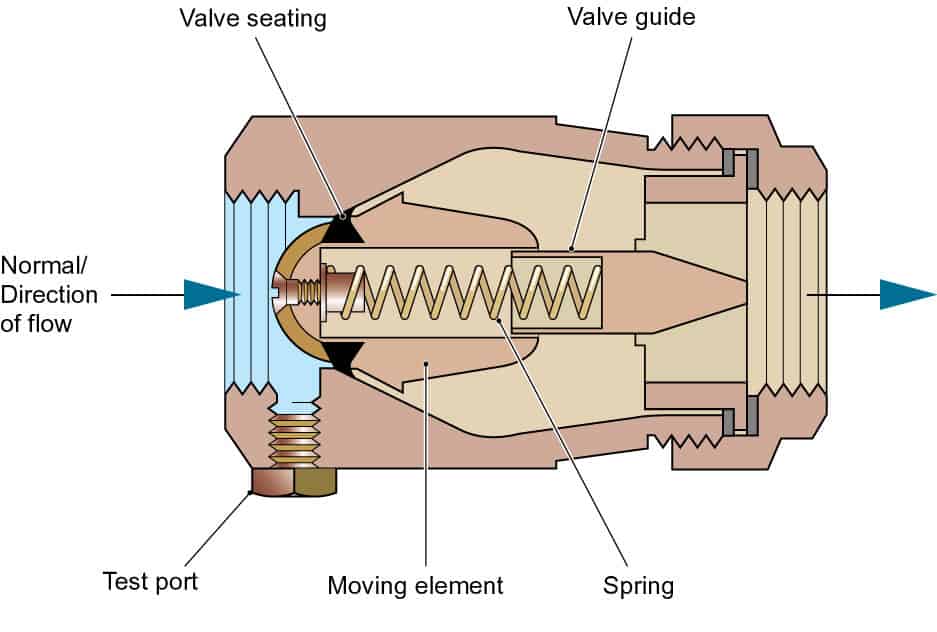

It lets fluid flow only in one path. This avoids fluid flow in the back direction. And which could cause pollution or destruction to other components. Check valves work and do not need to function. Most existing types have a small spring to close the valve. The medium pressure in the forward direction releases the valve. Note that the slightest pressure is vital to open the valve (cracking pressure).

How to Produce Brass Check Valve?

Introduction

Brass check valves are pivotal in many fluid systems, preventing backflow and maintaining steady, directional flow. Their non-return mechanism ensures that systems work efficiently, preventing potential damage and improving the lifespan of the equipment. But how are these essential components manufactured? This guide will delve into the meticulous process behind the production of brass check valves.

Material Selection

Choosing Brass: Brass, an alloy of copper and zinc, is the preferred material for many valves due to its corrosion resistance, machinability, and durability. Its composition can vary, affecting its hardness, resistance, and appearance.

Quality Control: Before manufacturing begins, the brass is inspected for impurities or inconsistencies. This step ensures that the final product will perform efficiently and last longer.

Design and Prototyping

CAD Designs: Modern valve production often starts with Computer-Aided Design (CAD) programs, where the valve’s design is conceptualized in a digital space, considering its size, pressure ratings, and specific use scenarios.

Prototyping: Before full-scale production, a prototype might be crafted to test the valve’s function and fit in real-world applications.

Forging and Casting

Forging Process: High-quality brass check valves are often forged. Brass bars are heated until malleable and pressed or hammered into valve shapes using high-pressure machinery.

Casting: Alternatively, molten brass can be poured into molds (casting) to create the valve’s body. This method allows for intricate designs but might require further machining.

Machining and Shaping

CNC Machining: Computer Numerical Control (CNC) machines provide precision in shaping the valve, ensuring accurate dimensions and threads.

Manual Adjustments: Even with the precision of machines, the human touch is sometimes necessary. Artisans might manually adjust or finish parts of the valve to ensure perfection.

Assembly

Integrating Components: The valve’s body, hinge pin, disc, and other components are assembled. This might involve screwing, pressing, or even welding parts together.

Quality Checks: After assembly, the valve is tested for leaks and functionality, ensuring the disc opens and closes correctly and there’s no backflow.

Surface Treatment and Finishing

Polishing: The valve is polished to a shiny finish to provide a sleek appearance and further protection against potential corrosion.

Coating: Some brass check valves might receive a thin protective or decorative layer, depending on the application.

Final Testing and Quality Assurance

Pressure Testing: To ensure the valve can withstand real-world applications, it’s subjected to high-pressure testing.

Inspection: Each valve undergoes a meticulous visual and functional inspection, ensuring no defects, such as misaligned components or rough edges.

The production of a brass check valve is a symphony of modern technology and traditional craftsmanship. From the initial selection of quality brass to the final rigorous testing procedures, each step is vital in ensuring the delivery of a reliable and efficient product. Understanding this process underlines the importance of choosing high-quality brass check valves for any application.

Brass valve assembly:

We will assemble your brass check valve from diverse parts. You will see the concluding valves after this procedure.

Water pressure testing:

We do 100% air pressure testing on your brass check valves before packaging and shipping.

Dimension of Brass Check Valve

| Size | H | L |

| 3/8 inches | 1.42 | 2.09 |

| ½ inches | 1.42 | 2.09 |

| ¾ inches | 1.56 | 2.36 |

| 1 inch | 1.77 | 2.62 |

| 1-1/4 inches | 2.07 | 3.19 |

| 1-1/2 inches | 2.17 | 3.55 |

| 2 inches | 2.74 | 4.22 |

Selecting the Right Brass Check Valve

Check valves come in different shapes and materials. The brass check valve is accessible in various kinds. Partiality for brass swing checks over brass ball check valves depends upon usage. Consider all likely options for choosing one type over another. Organizing custom valves is possible when the user specifies this to be serious.

How Does a Brass Check Valve Work?

Its working principle relies on letting flow in one path yet avoiding flow in the opposite direction. Brass Check valves are one of the only valves that are self-automated. Also, it does not need a human interface to cycle them.

The making of this valve is simple, including constituents such as a cover, body, seat, and disc. These valves are sensitive to flow and rely on media to open and close the seat. The inside disk allows media to flow ahead, which forces the valve to open. The flow is then inverted, closing the valve.

Brass check valve mechanism based on the differential pressure principle. In a check valve, the minor differential upstream pressure name is cracking pressure.

The cracking pressure plays a vital role in opening and closing this valve. This cracking pressure differs according to the design and size of different check valves.

Yet, the cracking pressure turns higher than the upstream pressure. The fluid tries to flow from the release side to the suction side. At this point, the valve shuts, preventing the fluid from flowing back.

This shutting process of the valve varies according to the size and design of the valves. Spring pressure or gravity helps to shut the valve. Most check valves have an arrow sign on their body representing the fluid flow direction.

Types of Brass Check Valve:

Brass Spring Check Valves:

Spring check valves a large stopper and hollow bodies that gets continuous pressure from a spring. When gas or fluid runs forward at high pressure, the force will overcome the pressure from the spring. It causes the stopper to open, letting the wanted flow.

Disparate swing check valves. Spring check valves offer low sound levels. They also lessen the sound and destructive effects of water hammers. This kind of valve works well in vertical usage. Yet as it uses a spring to close the valve, then depends on pressure and gravity.

Applications of Brass Spring Check Valves:

Spring check valves are perfect for many reasons in water pipelines and systems. This kind of valve guard’s equipment against the loss that can begin with backflow. Additionally, these valves release pressure from the system to form a safer atmosphere. Yet confirm proper system function.

Brass Swing Check Valves:

In brass swing check valves, a flapper will sway away to let the forward flow of a gas or fluid. When it is time to stop the flow, the flapper will rock back onto the seat—closing the valve as the system pressure drops. Swing check valves are famous due to their large flow capacity. These devices need a swinging motion to work. In comparison, their use is partial to vertical upward and horizontal flows.

Applications of Swing Check Valves:

Swing check valves task well with diverse media, including gases and liquids. Some use situations for swing check valves include flood limitations in sewage systems, toilet flush mechanisms, and firefighting equipment.

Dimension(mm):

| Size | D | L | H |

| ½ “ | 33.5 | 12.5 | 48.5 |

| ½ “ | 41 | 13.5 | 51.5 |

| ¾ “ | 46 | 14.5 | 59.5 |

| 1″ | 56 | 17 | 67.5 |

| 1-1/4″ | 64 | 17.5 | 72 |

| 1-1/2 “ | 80.5 | 19 | 82 |

| 2″ | 103 | 24 | 99 |

Brass check valve applications

A brass check valve regulates the flow of gases and liquids—valves made from brass, a material that recognizes strength and resistance to rust. Brass check valves are often used in sanitation. Yet also in industrial usage, where it is vital to keep the flow of gasses and liquids under control.

Brass check valves intend to let liquids and gasses flow in one way only. This avoids backflow and guarantees that the flow of liquids and gasses control. Brass check valves are used in gas lines and water lines. They also operate pumps and air compressors. Brass check valves offer in both socket weld and threaded variants. It makes them adaptable enough for many diverse kinds of systems.

Benefits of brass check valve

This kind of valve holds many benefits, comprising corrosion resistance. Yet the capability to endure and absorb heat well. More advantage is its flexibility. Yet, it welds to meet application requirements and the system. One sign of this kind is that it can break down when there are significant chlorine levels. Yet, it is used for drinking water applications.

Brass check valves are usually used in a diversity of industries. Because of their durability and reality. These are some of the benefits of using brass check valves:

1. These valves are much more durable and robust. Meaning they can survive high temperatures and pressure. This makes them perfect for the oil, gas plumbing, and automotive industries.

2. These valves are easy to fix and maintain, making them a low-cost solution for many trades.

3. Brass check valves are tough to rust. Meaning they will last longer in severe environments.

4. These valves have a very low friction coefficient, which means they are close and open and with low stiffness.

Bottom Line

A brass check valve is a kind of valve that aids in avoiding reverse flow in a piping system. This simple device is a disc or poppet with one or more ports resting against the seat when the valve closes. Check valves are very communal in plumbing systems.

The installation of check valves:

The check valve guarantees the flow direction of the water inside the pump. So on, ensure the usual process of the pump. So, should the check valve’s fixed position be set in front of the pump? Although in after, the pump can divide into two states:

There are two ways to fix brass check valves:

- In front of the pump:

Fix the check valve on the end of the vertical suction pipe before the pump.

She also called the bottom valve; the check valve once fills the pump with water. And for all, you don’t have to fill it whenever forcing water. Because there is no water in the pump and the suction pipe before the pump, the pump can only be idling and can’t pump water.

The pump must fill with water to pump water. This installation method for the pump is suitable when the pump is higher than the liquid level. However, this is also called the harmful pressure method.

- Behind the pump:

The valve is fixed in front of the water pump and at the end of the upright suction pipe called the bottom valve. This kind of fixation works at higher than water or liquid level. It is also called the harmful pressure method. The central target of fixing the valve in front of the pump is to occupy the pump Yet unless letting it flow idle free of any water.

The second method of fixing the check valve behind the pump is perfect when the liquid level is upper than the pump. This helps the easy closing and opening of the water pump deprived of closing the pump outlet valve.

This fixing method is valid for the initial and ending pump without closing the outlet valve. The female controls the pump system to avoid backflow when the fluid level exceeds the pump.